… what is the level of scale in your water? Hard to say, I’d imagine. But, over time, believe me, you’ll know. Scale, also known as limescale, refers to mineral buildup—primarily magnesium and calcium—that creates a white, chalky-like substance that can accumulate on the plumbing system’s internal components, including water heaters, pipes, and fixtures, says Read more

heating and cooling

… what is the level of scale in your water? Hard to say, I’d imagine. But, over time, believe me, you’ll know. Scale, also known as limescale, refers to mineral buildup—primarily magnesium and calcium—that creates a white, chalky-like substance that can accumulate on the plumbing system’s internal components, including water heaters, pipes, and fixtures, says Randall Oshiro, Lead Engineer, Noritz America.

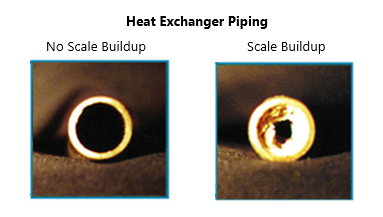

In other words, “Common in household water, especially in areas with hard water, scale is essentially the crusty stuff you sometimes see on old pipes or the heating element of an old kettle,” says Ben Tate, National Sales Manager—Water Treatment, Navien, Inc. “When water is heated, these minerals crystallize and stick to surfaces such as the interiors of pipes, boilers, and heaters, forming a hard, insulating layer. It’s a natural process, but not exactly a welcome one, as it hampers the efficiency of any appliance it settles in.”

Scale’s Geography

Scale’s prevalence comes down to the geological makeup of the land through which your water travels. Water is a universal solvent, and as it moves through soil and rock, it picks up minerals like calcium and magnesium. In areas rich in limestone and other calcareous rocks, which are composed mainly of calcium carbonate, water tends to carry a higher load of these minerals. Consequently, regions with such geological features—think of areas like Texas and Florida—often struggle more with hard water and, by extension, scale.

Calcium and magnesium are naturally occurring minerals, says Oshiro. Depending on where the water is drawn from, water flowing through ground sources that contain high concentrations of these minerals will absorb some of the minerals. For example, water drawn from an aquifer with a high concentration of limestone will inevitably have a high concentration of lime (calcium). Like the previous example, areas where water is drawn from underground are often where the highest concentration of hard water exists.

A Water Heater’s Nemesis

Yet the “damage” scale can bring can’t be overstated, says Dan Giosia, Assistant Product Manager, Bradford White Corporation, “The accumulation of scale in a water heating system diminishes the overall performance, efficiency, and lifespan of the water heater unless preventative maintenance measures are implemented.”

Scale poses a triple threat to water heating systems, says Tate. First, it’s an insulator. In a domain where efficient heat transfer is key, scale is a formidable barrier that keeps heat from doing its job effectively, which can drive up energy costs as your system struggles to keep up. Second, scale buildup increases the pressure in water lines and heating chambers, which can lead to leaks or mechanical failures. Lastly, the more energy and repairs a system requires, the more its lifespan diminishes. That’s why preventing scale isn’t just about maintaining water flow; it’s about saving money and extending the life of your equipment.

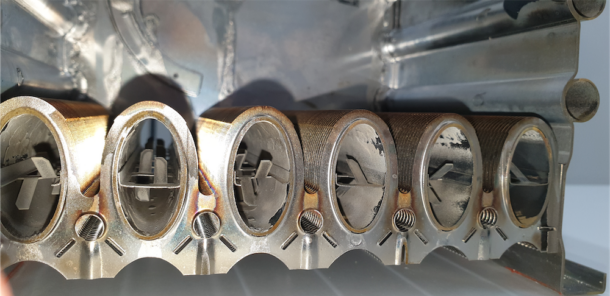

According to Oshiro, the primary danger of this scale formation is that it can accumulate inside the water heater (on the heat exchanger of tankless water heaters, along electrical heating elements, or along the internal flue of gas storage water heaters). This scale formation acts as an insulator in large amounts, preventing the proper heat exchange between the water and the heating source. “When this happens, the temperature will increase—as heat is not being drawn away at the designed rate—leading to increased thermal stress and decreased longevity of the internal components. Additionally, this buildup can reduce the surface area of piping, which can reduce the flow performance of the fixtures as well,” says Oshiro.

Tankless Magnified

Scale impacts both tank-type and tankless water heaters, though it manifests differently in each system, says Tate. In tank-type heaters, scale settles at the bottom of the tank, reducing heat transfer efficiency and leading to increased energy consumption and potential corrosion. Over time, this can significantly shorten the lifespan of the heater. Conversely, tankless models, which heat water directly, experience scale buildup directly on their heat exchangers. This can decrease heating efficiency and disrupt water flow, though it does not necessarily indicate a greater susceptibility to scale than tank-type heaters.

Regardless of the system type, the key to mitigating scale effects lies in regular maintenance. Both tank-type and tankless water heaters benefit from routine descaling and the proactive use of water treatment solutions like water softeners or scale inhibitors. Properly maintained, both systems can handle scale effectively, ensuring efficient operation and extending the lifespan of the heater. Thus, neither system is disadvantaged by scale when properly cared for, allowing users to choose based on their specific needs and preferences.

The reality is the mechanism/issue is about the same for both types of technology. “However, it will present itself much sooner/more apparently with a tankless type water heater than a tank-type water heater. The reason for this is basically that the pipes are smaller. Imagine a ¾” pipe and 24” round storage vessel. The smaller pipe, with a ¼” of scale buildup, loses significantly more of its surface area in comparison. This means that issues like reduced flow will become more apparent sooner,” says Oshiro.

However, it should be noted, continues Oshiro, that this same amount of scale will have the same actual effect on the systems (reduced efficiency, higher thermal stress). As a result, a tankless water heater may show signs of decreased performance sooner; however, this also allows the customer to preemptively conduct maintenance to ensure that the product will last many times longer than a storage tank-type water heater.

The storage tank-type water heater often continues to build up this scale over time, resulting in lower efficiencies (meaning higher operating costs) and eventual failure sooner. This scale formation is one of the primary mechanisms by which water heaters will fail. 1

According to Bradford White’s Giosia, scale does pose a greater issue for tankless water heaters compared to tank-type water heaters due to their compact heat exchanger design. With a limited surface area and brief heating period, tankless heaters must rapidly elevate water temperatures, requiring high temperatures within the heat exchanger. As a result, scale tends to accumulate on this surface. If scale buildup becomes excessive, it can restrict water flow through the heat exchanger to the point of causing component or unit failure so it’s important for homeowners to contact their plumbing professional for regular maintenance.

In comparison to gas tank-type water heaters, electric tank-type heaters are generally more susceptible to scale buildup. This is primarily due to the very hot surfaces of electric heating elements, which have a small area and are prone to accumulating limescale within the tank. However, the impact of scale buildup is limited by the fact that electric heating elements are relatively inexpensive to replace, especially when compared to the cost of replacing a tankless gas heat exchanger or complete unit.

Gas tank-type water heaters may vary in susceptibility to scale buildup depending on their design. Units with a burner located outside the tank are typically less affected by scale compared to those with an internal heat exchanger where scale can accumulate.

Action Plan

What can contractors/homeowners do to “combat” scale? “The first step is to know your water supply,” says Oshiro. “Almost every municipal water supply company will annually publish a water quality report that will include data about the hardness of your water supply. This rating will often be rated on a scale of grains per gallon (gpg), parts per million (ppm), or milligrams per liter (mg/L). These ratings tell the density of mineral hardness (calcium) present in the water supply. The USGS[1] has a relative hardness indicator, where 61-120 mg/L (3.6-6 gpg) would be considered somewhat hard water.”

The best way to reduce scale is to treat the cause. This means using water treatment devices to prevent the calcium from building up in your water heater and piping. However, this isn’t always possible, so maintenance can be conducted by a descale flush: running a deliming agent (ex., vinegar or a specialized deliming agent) solution through piping the water heater to neutralize the calcium. As calcium is a basic material (pH >7), the acidic deliming agent will neutralize the calcium and remove buildup.

It’s also essential to adhere to the manufacturer’s recommendations for preventative maintenance, including specific procedures and frequency, for their product, advises Giosia.

Regular descaling of the water heater is often recommended to minimize scale buildup on the heat exchanger of a tankless water heater. The frequency of preventative maintenance typically depends on the characteristics of the water supply in your area, such as whether it is heating hard or soft water.

Installing a water softener can help reduce the hardness of the incoming water into both tankless and tank-type water heaters. However, it’s important to consult with a plumbing professional to ensure compatibility and to follow their recommendations.

Navien’s Tate says contractors and homeowners in these regions should adopt a proactive approach to water treatment. Installing a water softener is one effective strategy; it replaces hardness ions like calcium and magnesium with sodium or potassium, preventing them from forming scale. Additionally, I’d recommend considering scale prevention systems, which are designed to transform hardness minerals into harmless crystals that won’t stick to surfaces. Regular maintenance checks are also vital—they help ensure that any potential scale buildup is managed before it becomes a serious issue.

If you know that your water source is hard water, Oshiro suggests that you can take action to alleviate the risks.

- Develop a routine maintenance plan: This can be done by “descaling,” or flushing, your water heater regularly, depending on usage and quality. Asking your water heater manufacturer or installer for recommendations on frequency is a great first step.

- Treat the water: There are ways to eliminate (sequester or remove) hard-water minerals from the water source. These include items like water softeners, which use an ion-exchange process to physically remove free calcium from the water, or products that use a polyphosphate media to sequester the calcium to prevent it from coming out of the solution when heated.

Technology Tips

Is there newer technology that could make the equipment more scale-resistant? “Indeed,” says Tate. “One of the latest advancements in this area is Template Assisted Crystallization (TAC), which is a highly effective technology for preventing scale without the use of chemicals or salt. TAC systems work by transforming the calcium and magnesium minerals in hard water into stable, harmless crystal particles. These particles then flow through the system without sticking to surfaces, effectively preventing scale buildup. This technology is particularly useful for protecting high-efficiency tankless water heaters from scale, ensuring they operate at optimal efficiency while extending their lifespan.”

To some degree, says Oshiro, the selection of materials, design of the heat transfer surface, and the temperature in which the system operates, all have roles to play in controlling the amount of scale formation.

- Materials with less surface roughness provide less chance for scale particles to attach.

- Systems with lower temperature rises can also slightly reduce the formation rate of scale.

There is constant research into reducing the harmful effects of scale formation in water heating products, but at its core, it is a challenging situation to avoid entirely.

According to Giosia, some tankless water heater models incorporate technology aimed at enhancing scale resistance, such as scale reduction technology and replacement filtration cartridges. Moreover, water softeners can serve a similar purpose in mitigating scale buildup.

However, despite these advancements, maintenance remains essential for all tankless water heaters to prevent excessive scale accumulation. Regular upkeep is necessary to ensure optimal performance and longevity of the unit.

In conclusion, the timeline for significant damage can vary widely depending on the water’s hardness and the frequency of system maintenance. In regions with very hard water and minimal preventive measures, says Tate, significant scale buildup can occur within just a few months, leading to efficiency losses and potential system failures. Conversely, with proper management and regular maintenance, scale-related damage can often be staved off for years, preserving the efficiency and extending the life of the system.

1

https://www.usgs.gov/special-topics/water-science-school/science/hardness-water#:~:text=Measures%20of%20water%20hardness&text=General%20guidelines%20for%20classification%20of,mg%2FL%20as%20very%20hard

Located in rural British Columbia, Lesley McGlenen has a much greater impact on the skilled trades than her small company would lead you to believe. Online, McGlenen goes by @ThePipeWench. She’s a plumber, gasfitter and hydronic professional. Most of her work is residential, but she dabbles in commercial work from time to time. From her Read more

Located in rural British Columbia, Lesley McGlenen has a much greater impact on the skilled trades than her small company would lead you to believe.

Located in rural British Columbia, Lesley McGlenen has a much greater impact on the skilled trades than her small company would lead you to believe.

Online, McGlenen goes by @ThePipeWench. She’s a plumber, gasfitter and hydronic professional. Most of her work is residential, but she dabbles in commercial work from time to time. From her shop in Scotch Creek, she travels to jobsites around Shuswap Lake, typically venturing up to two hours from home.

McGlenen’s father was a general contractor when she was young. She’d lend a hand where she could, cleaning up and helping on jobsites. Eventually, a plumbing contractor noticed her work ethic and offered her a job. She enjoyed the job for a while before trying her hand at cabinet making, all the while picking up skills that would aid her journey in the trades.

Eventually, plumbing called her back and she endeavored to finish her plumbing apprenticeship. Today, 17 years later, she’s sole proprietress of Pipe Wench Plumbing, Ltd.

Eventually, plumbing called her back and she endeavored to finish her plumbing apprenticeship. Today, 17 years later, she’s sole proprietress of Pipe Wench Plumbing, Ltd.

“I love this trade, and the variety it provides,” said McGlenen. “I’d get bored if I did the same thing day in and day out. The diversity of work creates a few challenges, but they’re not overwhelming. Different people, places and the occasional challenge keep me on my toes.”

She loves the job so much that she felt a calling to help other women become part of the skilled trade workforce.

A heart for women in the trade

“I want to impact and empower women to see the trades as a viable career,” said McGlenen. “There’s no proper direction in school. School systems aren’t asking young women what they really want to do. Even if they did, few would say they want to be plumbers, pipefitters or HVAC techs because the awareness isn’t there.”

McGlenen’s father didn’t push his own kids—two daughters and a son—toward the skilled trades because from personal experience how it can be hard on the body.

“Because the school system doesn’t present the trades as a high value career path, young men and women alike are left to find their own way. The big difference is that the skilled trades are more intimidating for potential female apprentices.”

“Because the school system doesn’t present the trades as a high value career path, young men and women alike are left to find their own way. The big difference is that the skilled trades are more intimidating for potential female apprentices.”

“I hear comments from time to time that young women are afraid of sexual harassment on a jobsite full of men,” said McGlenen. “I’ll admit, I’ve encountered some of that, but it’s always been a ‘bad apple’ scenario. The vast majority of men I encounter at work are very respectful. The ones I worked with early in my career were great guys.”

“There’s one other thing to consider,” she continued. “As sad as it is, women will face harassment in any job. Harassment isn’t exclusive to the skilled trades and it shouldn’t hang over the trades like a dark cloud. And it goes both ways. Men face harassment in the workplace from women, too. Harassment should not be a deterrent from this industry, and the fact that it’s still perceived this way shows a lack of knowledge and poor communication on our part.”

There’s a trade shortage in general, and women represent only two percent of the field—that alone represents a huge opportunity and room for improvement.

Because women in the trades are still such a rarity, McGlenen believes it’s important for women who’ve found their path as trade pros to speak openly about the broad range of possibilities.

“Women represent half the global population, yet we’re a tiny fraction of the skilled trade industry,” she said. “Why aren’t women jumping into the industry? Why do we feel our only path to success lies in a college education? It’s lack of representation, and that’s what I want to change.”

Taking it to the turf

After moving to Scotch Creek in 2020, McGlenen, an avid golfer, planned to host 30 of her friends at her local golf course. Then an idea struck her.

“I had this big group of women coming to golf, so why not make it a benefit tournament?” she said. “So, I made it official.”

In 2023, the first annual Babes GDGT (Goddamn Golf Tournament) was held at the Talking Rock Golf in Chase, BC, which benefitted the Women in Trades program at Okanagan College. “Funds raised at the golf event helped provide what women in the program need, including making the transition from the program to employment.”

“The goal of the event is to help women achieve the highest level of success possible in their selected skilled trade field,” said McGlenen. “We had 78 women at the golf tournament last year. That was a perfect number. Any more would have been too much for the first year, since I organized that event myself.”

McGlenen draws similarity between the trades and the game of golf. Both are arenas in which women often feel intimidated.

“I think it’s important for women to find excitement and challenge in golf – just as it is in the skilled trades,” she explained. “They need to make an initial push to overcome any hesitation they feel. I use golf as a business tool. Men do it, but women less so. The game can offer great networking opportunities. It’s just a matter of stepping out of your comfort zone.”

Intersecting interests

In 2022, McGlenen was signed into one of Taco Comfort Solutions’ Monday Night Live training sessions when Mike Miller, with Taco Canada, brought up the AHR Expo, suggesting that those in attendance meet up for a round of golf in Las Vegas.

So began the Taco Ryder Cup, in which a US team and a Canadian team go head-to-head on the golf course.

“It was great to meet Lesley in person and play golf with her, especially after seeing her on so many of our online training sessions,” said John Barba, Director of Training at Taco and an accomplished golfer. “She plays very well. For the record, Canada has beaten us both times, but neither of those losses were my fault! Lesley won both her matches and I won both of mine!”

“It was great to meet Lesley in person and play golf with her, especially after seeing her on so many of our online training sessions,” said John Barba, Director of Training at Taco and an accomplished golfer. “She plays very well. For the record, Canada has beaten us both times, but neither of those losses were my fault! Lesley won both her matches and I won both of mine!”

“Meeting the Taco trainers and so many of the people I’d seen on social media was so much fun,” said McGlenen. “I became a part of their learning community during COVID and it’s been invaluable since.”

The COVID lockdowns increased the need for online training for tradespeople across North America, but for McGlenen, the remoteness of her shop means that she needs to look online for training opportunities anyway.

“It’s nearly a three-hour drive for me to get to a training session hosted by a rep or wholesaler, and if I want factory training, it requires airfare. Instead, I just sign in to the “Taco After Dark” or “Taco Tuesday” training sessions. I can learn a lot from Dave Holdorf, John Barba and Rick Mayo without leaving my office. The availability of Taco’s tech support crew and the training I’ve received online gives me the confidence to tackle things I may not otherwise undertake.”

Taco appreciates what McGlenen is doing for the trade, so they’ve stepped up as a key sponsor for the 2024 Babes GDGT event. Mechanical Hub has also stepped up to help support GDGT this year with sponsorships.

Babes GDGT moving forward

The next Babes GDGT (@BabesGDGT) golf event will be held at Talking Rock Golf on June 8, 2024, and it’s already sold out with 128 golfers, and more than a few on the waiting list.

Unfortunately, Okanagan College’s Women in Trades Program was recently cut due to lack of provincial funding. But there are other schools in BC with similar programs.

“The fact that the program was cut illustrates how important it is for the trades to present a compelling and attractive pitch to women,” said McGlenen. “We hope to raise twice as much money this year, and we’re taking a close look at how best to support women in the trades with the funds we raise in June.”

In McGlenen’s battle to increase the skilled trade workforce, she’s quick to remind all tradespeople, not just women, that there’s more than enough work to go around. “Me against you” is the wrong mindset.”

“I hope that offering a new perspective, and enthusiastic advocacy for the trades will help to shift the demographic of tradespeople in Canada,” she continued. “There’s so much opportunity!

“With broader awareness of the trades, especially among women, it could lead to a win-win for all—from home and business owners to everyone in the trades,” she said. “We need to collaborate and develop better processes. It’s realistic and achievable, and I’ll do everything I can to help.”

Virtual and simulation training isn’t necessarily new to the industry but its acceptance has been met with intrigue, and trepidation. But to say that this is the future of training? Not so fast. The consensus thoughts regarding this type of training is that will never replace in-person or on-the-job training, but it will become a Read more

Virtual and simulation training isn’t necessarily new to the industry but its acceptance has been met with intrigue, and trepidation. But to say that this is the future of training? Not so fast. The consensus thoughts regarding this type of training is that will never replace in-person or on-the-job training, but it will become a cog in the overall “wheel” for training assets.

According to Taco Comfort Solutions’ Product & Application Instructor-East, Dave Holdorf, Taco doesn’t want to change its training necessarily, rather seek to enhance the training experience.

“We ask many attendees how we can improve our classes and seminars. One of the most frequent replies is: ‘Add a hands-on section to the class; the theory is great and useful, but I want to install.’

“In a classroom setting, this can sometimes be difficult for the space needed, the time it takes, and to accommodate the different skillsets of attendees. We believe we’re now on a track with virtual reality (VR) training to give that experience to attendees—whether they’re seasoned pros, or new to the trade. VR can help to guide participants in what to look for, and more importantly what not to do on a project,” says Holdorf.

F.W. Webb’s Michael DelConte checks out the VR display at the Taco booth during the AHR Expo.

Ken Midgett, former teacher and apprenticeship Instructor, Lehigh Career & Technical Institute, now Plumbing, Marketing Director with Interplay—whose mission statement is “Better Careers Better Lives”—believes that they can play a part in a person’s career trajectory with that person using Interplay’s content. “When a person engages in learning and increases both their fundamental knowledge and the steps to do a task, we are helping that person upskill and creating more career opportunities for them. The value of a product that interplay offers is the demand function. You do not have to wait until a class is offered you can just connect and learn,” says Midgett.

Adaptation to simulation and on-demand training is paramount to success for the learner and the business. Midgett says that traditional classroom learning for skilled trades is becoming more and more challenging for several reasons:

- Finding good instructors: Many think that because they know a skill, they can teach it effectively. As a former educator, this is not always the case. This leads to poor instruction and marginal learners who are not engaged.

- The cost: The cost of running and maintaining a hands-on training center is much higher than instructor salaries and consumables.

- Change or die: Young learners are not inept at learning from lectures. Most skilled trade learners need to be engaged with learning and it must represent meaningful learning.

- The disruption of classroom learning to the workday: A rationale for going to class in the evening for 2-3 hours is losing traction to young learners. Business owners become frustrated with learning times and days as they view this as unproductive time. Young learners need to be met where they are with training that fits their lifestyle.

Interplay Learning training, combined with the new employee with the right attitude who is coachable and willing to learn, can be an explosive combination with a win-win result. “Taking an apprentice and having them spend time training and learning with on-demand training and then pushing that person into the field with a skilled person to watch and do in the real world is the best way to train this person or persons at scale,” says Midgett, who says there are numerous other advantages to this model:

- On-job efficiency increases as the apprentice now possesses the foundational knowledge and skills to perform a given task.

• Relationships are better between the journeymen and the apprentice, as the journeyman perceives the apprentice as engaged and productive.

• Business owners experience low turnover, better culture, and increased revenue as these new hires have direction and are leaning at scale.

• Technicians feel confident in their work due to training and upskilling.

• Callbacks are reduced and remediation training for the technician to increase their confidence

• Service managers can focus on coaching and maintaining technician stats instead of being the only technical lifeline for numerous techs.

• When sending these apprentices to “factory training,” they can engage and understand this much better due to the foundational knowledge.

Nonetheless, Midgett says there are a few things to note and understand about simulation and on-demand training:

• On-the-job or hands-on training with higher skilled supervision cannot be replaced.

- Simulations are great at teaching steps and muscle memory of a task.

- Simulation or any on-demand training cannot teach “feel.” As an example, simulation training cannot teach the skill of what “tight” feels like with a pair of wrenches on threaded steel piping or how tight to make a tank-to-bowl connection on a closet, or how tight a screw should be on the control board. This is what the onsite skilled person or journeyman must understand and teach effectively on site.

“While VR, AR and simulation-based technology are great resources, I do not think that any one particular learning system or style is the future,” says Rich Camacho, CEO & Co-Founder, BlueRecruit. Having said that, Camacho utilizes Interplay’s services (all of Interplay’s certifications and courses live on BlueRecruit, and when a person completes an Interplay course, they can then add that qualification to their BlueRecruit profile to strengthen their profile for Employer) and he thinks Interplay is a fantastic tool to augment in-class learning and a great launch point for someone either just entering the trades or seeking to upskill a particular technique.

“However, at the end of the day true craft mastery will occur in the field with a wrench. As technology continues to improve and costs continue to decline, Interplay will play a larger and larger part of building the next generation of skilled trades professionals and we’re excited to work alongside them in building “Better Careers and Better Lives,” says Camacho.

Falls Church, Va. — For plumbing and HVACR contractors who are eager to make a difference, the Plumbing-Heating-Cooling Contractors—National Association (PHCC) is providing a timely opportunity to for them to do so by educating lawmakers during the May 21-22 PHCC Legislative Conference in Washington, D.C. As part of the conference, PHCC will facilitate visits between PHCC Read more

Falls Church, Va. — For plumbing and HVACR contractors who are eager to make a difference, the Plumbing-Heating-Cooling Contractors—National Association (PHCC) is providing a timely opportunity to for them to do so by educating lawmakers during the May 21-22 PHCC Legislative Conference in Washington, D.C.

As part of the conference, PHCC will facilitate visits between PHCC members and the offices of their elected representatives. The policy priorities for this year are:

- Protecting America’s energy future through fuel choice,

- Educating lawmakers on the costs and realities of building electrification,

- And supporting workforce programs and registered apprenticeships.

First-time attendees shouldn’t be nervous, as the event will provide personalized coaching by PHCC’s federal lobbyists, an easy-to-use app to help you navigate your Capitol Hill visits, and much more.

In addition to hearing from PHCC’s and other industry experts, attendees will hear from this year’s keynote speakers:

- Rep. Martin Frost (D-TX)

- And Rep. Tom Davis (R-VA).

These speakers will provide an objective overview of the state of politics during this pivotal election cycle. A complimentary copy of their book, The Partisan Divide, will be given to all conference attendees.

Are we beyond using the COVID pandemic years of 2020-2021 as a benchmark for anything moving forward? Ok, this will be my last but I felt that AHR 2024 knocked it out of the park, with attendance numbers equaling that of shows past, pre-pandemic. I actually heard, and this hasn’t been verified as of yet Read more

Are we beyond using the COVID pandemic years of 2020-2021 as a benchmark for anything moving forward? Ok, this will be my last but I felt that AHR 2024 knocked it out of the park, with attendance numbers equaling that of shows past, pre-pandemic. I actually heard, and this hasn’t been verified as of yet, but the day one on-site registration was nearing record levels. And day two crowds were still buzzing as traffic on the floor filled the aisles. (THIS JUST IN FROM AHR: It was clear to anyone filling the halls on Monday morning of the show that attendance was strong, welcoming 48,034 attendees there to interact with the 1,875 exhibitors spread across North and South Halls. )

To a booth, everyone was satisfied with the turnout and conversations during the show. The show marked a return to business as usual, at a much more accelerated pace. And to think, this is during mid-January, polar vortex temps, no less. (Don’t miss next year’s show February 10-12 in Orlando.)

U.S. Boiler Co.’s Ambient Heat Pump

Technology, innovation and new products dazzled, with heat pumps and the push toward electrification still dominating the topics of conversation. We heard more of VR and simulation training as a trending topic as well, with Artificial Intelligence, Workforce Development, Decarbonization all playing big parts at the show.

The Mechanical Hub team had a busy three days shooting videos in-booth, recording both Make Trades Great Again and Appetite for Construction podcasts, and we were even asked to emcee—and be a part of—a Coffee with Caleffi panel in the Caleffi booth on Monday morning. There, hosts John Mesenbrink and Tim Ward talked with industry bigs John Siegenthaler, Bob “Hot Rod” Rohr, Eric Aune and Andy Mickelson.

The discussion revolved around lifelong learning in the trades: where do these legends go to learn? Forgetting more than most of us will ever learn, Siegenthaler and Rohr talked about outlets for learning and continued training. Aune and Mickelson gave the point of view from a current business owner and working contractor, and the impact of social media in today’s PHVAC trades.

We can’t forget about the after-parties and the go-to for us has always been the Taco event Monday evening. It’s a chance to meet up with old and new friends alike.

From l to r: Eric Aune, John Mesenbrink, Ben White, Tim Ward, Mike Prencavage, Jr.

One event I had the pleasure of attending—and it was my first time—was the HVAC Tactical Awards extravaganza held at the Planetarium downtown Chicago. I believe this was the fourth annual event, and the tagline, “It’s a mindset” is turning into “It’s a movement.” This was another great event to see good friends, and the idea of night of “Blue Collar Goes Black Tie” can’t be overstated.

Ben Poole, HVAC Tactical

The industry needs events like this to showcase the trades in the best, shining light there is. And this event, with the red-carpet entry, exclusive red-carpet interviews, cocktail parties pre and post, and the awards ceremony, give this a gala-type feel, with everyone dressed to the nines, and I think everyone digs that vibe, at least for one night.

Links to AHR Expo Videos: