Leading manufacturer announces its continuing investment in the plumbing and HVACR trade organization’s training, education and workforce development programs Bradford White Corporation, an industry-leading manufacturer of water heaters, boilers and storage tanks, and the Plumbing-Heating-Cooling Contractors—National Association (PHCC) announce the renewal of their exclusive strategic partnership agreement and confirm their joint commitment to promoting and strengthening the Read more

heating

Leading manufacturer announces its continuing investment in the plumbing and HVACR trade organization’s training, education and workforce development programs

Bradford White Corporation, an industry-leading manufacturer of water heaters, boilers and storage tanks, and the Plumbing-Heating-Cooling Contractors—National Association (PHCC) announce the renewal of their exclusive strategic partnership agreement and confirm their joint commitment to promoting and strengthening the plumbing and HVACR industries.

The continuing partnership between two of the PCHP industry’s most trusted organizations reflects their shared mission to support professional contractors and their teams through investments in training, education, recruiting and advocacy resources.

“Our exclusive strategic partnership is based on the foundational values that drive Bradford White and PHCC,” said Joel Long, president of PHCC. “Bradford White’s deep, demonstrated commitment to the priorities of contractors aligns with PHCC’s dynamic initiatives for advancing the industry, and together we can enhance the positive effect we have on the lives of professionals on the ground who are providing essential plumbing, heating and cooling services now and in the future.”

Through its strategic partnership agreement with PHCC, Bradford White supports a range of scholarships, programs and initiatives dedicated to the advancement of contractor education and excellence, contractor business development, and promoting the value of the trades, including:

- The PHCC Educational Foundation, which provides innovative educational programming to enhance the growth and success of the plumbing and HVACR industry workforce.

- The SkillsUSA Plumbing Championship, a national competition for high school and post-secondary students featuring more than 16,000 competitors, instructors, industry representatives and volunteers.

- The Invest in Your Future Campaign, a fundraising effort supporting future workforce development.

- PHCC Education Partner, in support of PHCC education and training that provides PHC business owners and their employees with easy access to high-quality education and training opportunities.

“Bradford White’s unique relationship with PHCC through the years has given us an opportunity to elevate and amplify our investment in the plumbing, heating and cooling industry,” said Carl Pinto, Jr., senior director of marketing communications for Bradford White. “Supporting the hard-working professionals in our industry and developing future generations of PHC experts not only enhances the current state of our profession, it’s critical to ensure safe, reliable delivery of essential services for years to come.”

For more information about Bradford White Corporation, visit https://www.bradfordwhitecorporation.com.

It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing. Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his Read more

It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing.

Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his own company since 2014. At the age of 18, Bickerton started into plumbing, working for a larger residential company doing large multi-unit buildings where he worked for 2 1/2 years before moving to a smaller company doing mainly commercial work.

The itch started for Bickerton when he started in construction over the summers during high school, working for a roofing company and a general contractor, basically doing whatever was needed on a job site. “I tried helping whoever needed to be helped on the site—plumbers, electricians, carpenters—cleaning up, making coffee runs, etc. I remember those summers working for the GC and I enjoyed helping the plumbers more than anything else. I realized I was falling in love with the industry, and the rest is history,” says Bickerton.

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Bickerton recalls speaking to his father, and a few other people he knew who worked in the trades, and was pushed in the direction of electrical or plumbing mainly because, “you’ll never be looking for work.”

After obtaining his Journeyman Plumbing and Gas Fitting License in 2008, Bickerton completely shifted gears and joined the United States Marine Corps where he was deployed to Afghanistan. It was a difficult decision but joining the military was something Ryan had always wanted to do. In 2008, it was the right time. After six years of service with the Marines, Bickerton returned to plumbing and got his Master Plumbing and Gas Fitting License. “I started doing more and more side work until I landed a few bigger jobs that motivated me to leap into owning my own company. I haven’t look back since,” says Bickerton.

Part of that drive came from his biggest role model, his father, who worked most of his life in a power plant in South Boston as a general mechanic—he could pretty much fix anything and everything that needed fixing. “My father is the hardest working person I know. I remember as a young kid not seeing him for days at a time because he was getting home late and leaving early before we were awake. I knew he was out working hard taking overtime to provide for us. He could and would fix most things around the house. I remember one year our water heater went out on Thanksgiving and he took care of it by himself. I thought that was pretty cool, and still do,” says Bickerton.

As for Ryan, he never considered himself a role model, but he tries to conduct himself that way. Any chance he gets, he’ll speak highly of the trades. “If any young kids ask me about the trades, I do my best to steer them in the right direction and let them know it’s a very viable option. It’s a rewarding career choice, and college and white-collar work doesn’t have to be for everyone,” says Bickerton.

Bickerton does rough-ins to beautiful renovations.

Bickerton’s trade role model was his first foreman, Mike Sheehan, a plumber for 30+ years, his body broken from years of moving massive boilers and extra heavy cast-iron pipe. “But he still loved the trade. He taught me a lot of my early skills, and he would say that this trade has all the potential to do anything you want with it, which has really stuck with me to this day,” says Bickerton.

Bickerton’s go-to tool has been the ProPress/MegaPress. “Don’t get me wrong, I loved to solder and took great pride in having clean joints, and still think it’s a necessary skill to have, but the press system is a complete game changer.”

While respecting these two men’s work ethic, Bickerton knows that balancing work and family life is important. It’s probably his most difficult task, says Bickerton. “I’m usually out the door by 5 am and home around 5 pm, and the kids go to bed between 7:30-8 pm and then most nights I have to do estimates or invoices when they’re in bed so I don’t have as much ‘leisure time’ as I’d like. I try to make every second I’m home count.”

And the weekends are for family. Bickerton used to work every Saturday and even some Sundays. Lately, however, Ryan doesn’t work Sunday unless it’s a catastrophic emergency, and on Saturdays he tries to be done by 12 or sometimes not at all. “Like I said before, I love plumbing and working but I don’t think I’ll ever regret not working more and spending less time with my family so I try to best divide my time in the fairest manner possible.”

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

Perhaps family means a bit more to Bickerton because his daughter, Mallory, was diagnosed with a rare genetic disorder called Rubenstein Taybi Syndrome (RTS). In 2017, Ryan and Micayla, along with some close friends, started a non-profit organization called Mals Pals Foundation. “We have been very fortunate with Mallory. We live in the epicenter for healthcare; she has had an inclusive educational opportunity here in Boston and it helps that we are able to pay for anything and everything she has needed in order to thrive,” says Bickerton.

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mallory is now seven-years-old and doing well. “Initially, there were concerns, but honestly, I wouldn’t have it any other way,” says Bickerton.

Bickerton looks forward to going to work every day. “But the most rewarding to me is being able to sit back at the end of the day or at the end of a job and look at what I’ve done,” says Bickerton. “I like having something tangible, that I can look at and touch and say I did that, or I fixed that or I created that. Whether it’s fixing a leaking faucet, creating a bathroom where there wasn’t one before, plumbing a 5-unit building completely from scratch or providing someone with heat and hot water for the next 20-30 years. That’s pretty cool.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

Propane CHP units offer resiliency, efficiency, and environmental protection Driven by the rising costs of electricity and increasing frequency of power outages, homeowners across the country are searching for energy solutions that are affordable, efficient, and reliable. When it comes to efficiency, there’s no doubt that micro-combined heat and power (micro-CHP) beats electricity supplied over Read more

Propane CHP units offer resiliency, efficiency, and environmental protection

Driven by the rising costs of electricity and increasing frequency of power outages, homeowners across the country are searching for energy solutions that are affordable, efficient, and reliable.

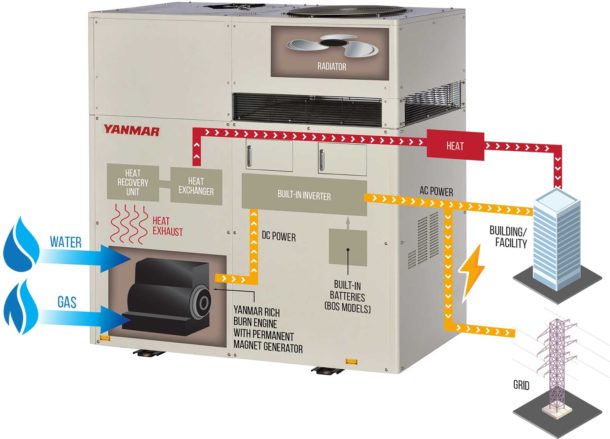

When it comes to efficiency, there’s no doubt that micro-combined heat and power (micro-CHP) beats electricity supplied over the grid. No longer limited to industrial and manufacturing applications, high-efficiency CHP systems have been making their way into more project types—including residential homes—through smaller micro-CHP units.

The basics of CHP and micro-CHP systems

The concept behind the micro-CHP system is simple: The unit replaces a traditional furnace or boiler and water heater with a single appliance that produces both hot water and heat as well as electricity for use in the home. Because the unit runs on propane and many units can start without power from the grid, it offers resilience and energy independence in the event of a power outage without the need for a standby generator.

Suppliers and builders who work with the technology say it can add up to considerable savings over time based on factors such as home size, location, and local electricity costs, but the value of CHP and micro-CHP units can be found nationwide.

Available in a wide range of capacities, CHP systems are ideal for single-family homes, apartment buildings, small businesses, utility power, and large commercial and industrial applications. For example, 1-3 kW units are ideal for 1,800-2,500 square foot single-family homes, 3-10 kW units work well for single-family homes with greater heating loads (like pool heating) and multi-family commercial and light industrial applications, and 10-50 kW units can power residential apartment buildings and commercial buildings (like restaurants).

Micro-CHP systems offer unmatched efficiency

A propane-powered CHP and micro-CHP unit’s total efficiency far outpaces the efficiency of traditional heating or water heating systems, providing operational savings from even the most efficient boilers.

According to the U.S. Environmental Protection Agency (EPA), the electricity that comes to a typical single-family home in the U.S. is only about 33 percent efficient. That’s because the heat used to generate it in a coal- or gas-fired power plant is lost, as is some of the electricity during transmission over high-voltage power lines.

Compare that to micro-CHP, which uses an on-site gas- or propane-fired engine to generate electricity while capturing the engine’s heat to produce hot water. These systems are typically 60 to 80 percent efficient, with some systems nearing 90 percent efficiency, according to the EPA.

CHP units are clean and environmentally friendly

Propane-powered combined heat & power (CHP) units produce significantly fewer harmful emissions, making it a better option for everyone—including customers. And as construction professionals know, environmental considerations continue to grow across the residential market.

Notably, the micro-CHP unit can reduce a home’s carbon dioxide emissions by nearly 50 percent, or 4.2 tons of carbon dioxide per year. Additionally, propane models reduce nitrogen oxide (NOx) emissions by 13 percent compared with natural gas and 50 percent compared with electric.

To determine if propane is the right fit for your next residential project, visit Propane.com.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Recognized for his outstanding leadership and dedication to his students at Norfolk Technical Center in Virginia, Anthony Bertolino was named the Plumbing-Heating-Cooling Contractors—National Association’s (PHCC’s) 2021 Plumbing Instructor of the Year. The award – sponsored by PHCC Corporate Partner Milwaukee Tool – was presented this week during PHCCCONNECT2021, the association’s annual conference, held in Kansas Read more

Recognized for his outstanding leadership and dedication to his students at Norfolk Technical Center in Virginia, Anthony Bertolino was named the Plumbing-Heating-Cooling Contractors—National Association’s (PHCC’s) 2021 Plumbing Instructor of the Year. The award – sponsored by PHCC Corporate Partner Milwaukee Tool – was presented this week during PHCCCONNECT2021, the association’s annual conference, held in Kansas City, Missouri.

“The instructors in the p-h-c field play a crucial role in developing tomorrow’s workers,” said 2020-2021 PHCC President Hunter Botto during the award presentation. “We are fortunate to have high-caliber men and women who devote their time – both on and off the clock – to prepare students for rewarding careers in our industry.”

Bertolino is “an exceptional teacher and role model for his students,” added Botto. In addition to running Bertolino Plumbing & Heating in Virginia Beach, Virginia, with this brother, he teaches all four years of plumbing apprenticeship at Norfolk Technical Center. He has dramatically improved both the retention rate for each class and the number of students, and his program is one of the largest in Virginia.

Ironically, Bertolino did not originally plan to become a plumber but rather study business in college and become a floor trader in New York City. After his father, a licensed plumbing contractor, explained the expenses involved with that plan, however, Bertolino considered plumbing. He enrolled in an apprenticeship program, earned his journeyman’s license, and – less than two years later – received his masters’ licenses.

This is one of the first stories Bertolino shares with his students. “I tell them that I have no student debt; I own my own business; and I really enjoy what I do,” he said. “I also tell them how much I have learned and that this is the career I chose.”

As an instructor, Bertolino’s effectiveness is more than charisma and straight talk, however. He incorporates the Montessori method of education that is based on self-directed activity, hands-on learning, and collaborative play. He engages students by sharing examples of his own on-the-job challenges and encourages them to discuss their work experiences to help advance the entire class.

“Tony’s students know that he expects them to apply their classroom knowledge to the day-to-day work and that licensure is the mark of professionalism,” Botto said during the award presentation. “He reminds them of the importance of plumbing to the health and safety of the nation.”

Bertolino’s connection with his students doesn’t end when their apprenticeships are completed; he stays in touch with many of them for years and keeps a collection of stories about the good things they have done in the trade. PHCC and Milwaukee Tool proudly recognized Bertolino’s ongoing commitment to these young professionals with this Plumbing Instructor of the Year award.

In an unprecedented time, newly elected PHCC president Joel Long says it’s time stop living in fear, and getting back to work is a top priority. Recently, Mechanical Hub had the chance to talk with Joel Long, co-owner of GSM Services, Gastonia, N.C., and PHCC president-elect. Running the nearly 100-year-old business with his brother Steven Read more

In an unprecedented time, newly elected PHCC president Joel Long says it’s time stop living in fear, and getting back to work is a top priority.

Recently, Mechanical Hub had the chance to talk with Joel Long, co-owner of GSM Services, Gastonia, N.C., and PHCC president-elect. Running the nearly 100-year-old business with his brother Steven. Joel started to work for the family business during high school summer breaks and fell in love with the business. After high school, Long attended North Carolina State University and graduated with a Bachelor of Science (BS) degree in Civil Engineering and Construction and started working for the family business upon graduation. In the following Q&A, Joel talks about his vision for PHCC and some critical issues facing contractors today.

Recently, Mechanical Hub had the chance to talk with Joel Long, co-owner of GSM Services, Gastonia, N.C., and PHCC president-elect. Running the nearly 100-year-old business with his brother Steven. Joel started to work for the family business during high school summer breaks and fell in love with the business. After high school, Long attended North Carolina State University and graduated with a Bachelor of Science (BS) degree in Civil Engineering and Construction and started working for the family business upon graduation. In the following Q&A, Joel talks about his vision for PHCC and some critical issues facing contractors today.

MH: What does the position of PHCC president mean to you?

LONG: I am honored to have this opportunity to serve our industry and association after it has given so much to our company and to me personally. I am thrilled to such a big opportunity to continue the work of those who have served before me and to make a little progress for our members and partners.

We are in a unique position to understand the depth of caring from the PHCC family. As many may know, tragedy befell GSM Services in April of this year with the murder of two of our coworkers. It was devastating to say the least, but PHCC members supported these two families on a massive scale and proved once again there is more good in the world than evil.

MH: What are some things you can take from your career that you can apply in the next chapter as president of PHCC?

LONG: There is nothing quite like the experience you gain while growing up in businesses like ours and then growing into a leadership position in that same business. I have spent a lot of time at the state and national levels seeing what works, what causes issues, and what is broken. I am going to use that experience to hopefully continue to move us forward.

MH: How do you think being in the trades will guide you as the next president of the PHCC?

LONG: I think I fell in love with our trade because the people at all levels are just the best of America. I have always loved how we have a “can-do” attitude and can conquer anything while focusing on our families and doing what is right. PHCC will be operating that same way in my year as president like we have since our founding.

MH: The last 18 months has been quite the experience. What do you tying will be some of your initiatives going forward as we seem to be moving post-COVID?

LONG: I would say we may look back and see these two years as some of the most challenging in our careers. Our members faced many challenges related to the pandemic and PHCC was able to provide a ton of assistance on those fronts.

Our members were deemed essential during the pandemic and continued to send our workforce into client’s homes and businesses as the disease raged. Protecting both customers and coworkers was a major concern all-across the country. PHCC got out front early with our Covid Recovery Center and our members were able to use our center to stay informed of changes and best practices to overcome the pandemic issues. We will be continuing that effort.

I also believe it is time to get back out on the road and live without fear. We are going to lead by example and get our association moving back in a pre-pandemic mode. We must be as safe as possible and respect the concerns of the public, but at the same time we must get back to work on a full-size scale!!!! It’s time to go!

MH: What is your vision to take PHCC to the next level?

LONG: PHCC is a federation of state and local associations and I believe it works best when each level is openly communicating and helping each other reach our individual and combined goals. Communication and collaboration are key to our mutual success. There are so many different opportunities across the country, and we must be very nimble and targeted in our approach to help our partners. We are here to serve our contractor members first and foremost, but our customers are also our state associations. Strengthening those relationships and building on small successes is how we will take PHCC to the next level.

MH: What are some critical issues facing contractors today?

LONG: I have heard from contractors all over the country and they are concerned about how they are struggling to get back to work through all the roadblocks we have been facing this past year or so. We will obviously continue to see the pandemic making us adapt our businesses going forward, but there are also opportunities for growth all around if we continue to search for them. I encourage our members to use PHCC and our members as resources to help find new growth opportunities and information to help your business thrive.

MH: How do we find and inspire the next generation of coworkers?

LONG: I love the movie The Untouchables with Kevin Costner and Sean Connery. One of my favorite scenes is when they are trying to find uncorrupted new recruits for the Treasury Department and they decide to go to the academy to get untainted recruits. We need to do the same to find the next generation.

Before the pandemic, PHCC had developed our online apprenticeship program and we were already having good success in giving students a pathway for a career. As the pandemic grew, our members really started using this as a recruiting tool to convince high school students and their parents that a career in our industry made a ton of sense without the college debt.

I believe today’s youth is looking for a career that helps them grow intellectually, gain financial independence, give opportunities to improve the world, and have opportunities for career advancement. We must continue to get he word out about how our industry can help them achieve their goals.

We must also continue to expand these efforts by widening the exposure of this program to other avenues on a state be state level. We will be encouraging our chapters to partner with as many local school districts, community colleges and HBCU’s about how to expand our opportunities.

MH: Finally, what do you like to do in your spare time?

LONG: I am a sports nut and love college football. I have followed NC State athletics since elementary school and continue to follow today, and as I say every year, this is the year we win the College Football National Championship! Eventually I’ll be correct, right? Also, if you bump into me and have an extra hour, just ask me about being at State when Jim Valvano was our basketball coach.

I also love fishing. Grew up with my father fishing on many Saturday mornings, and I love the time to unwind and reflect from the business. I also love the variety of fishing in N.C. We have wonderful fishing in the intercoastal waters, fresh water lakes all over the state, and my current favorite, trout fishing in the North Carolina mountains.