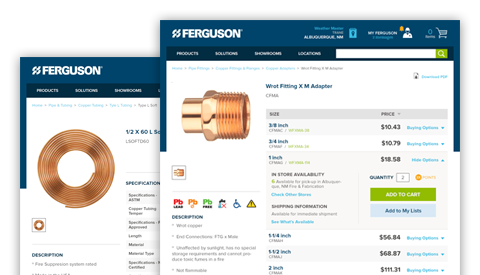

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource. As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover Read more

HVAC

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource.

As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover, running a successful plumbing business requires access to quality products, reliable suppliers, and expert advice. In today’s digital age, having a robust online platform can significantly streamline your operations and contribute to your business’s growth.

In today’s post-COVID world, especially dealing with disruptive supply chain issues, it almost goes without saying; you can never have too much inventory on the truck or back at the shop. That’s why I rely on Ferguson.com, a comprehensive website that has plumbing contractor-specific resources available, all of which are literally just a click away. And that click provides real-time stock and pricing of more than 200,000 HVAC and plumbing products; I can see what’s in stock and my contract pricing.

My plumbing business relies on my wholesaler to carry a vast range of top-quality products from leading brands, and I trust Ferguson to provide those trusted, reliable, and durable solutions. Whether I’m looking for pipes, fittings, valves, fixtures, boiler parts or specialty items, I look to Ferguson.com.

Some really helpful features include “My Lists.” I am able to customize the order process with just a few clicks, instead of individually searching for the products I purchase regularly and organizing lists of the products I want. This ultimately has saved me time and has helped to streamline my ordering process. Ferguson.com even gives me the ability to share those lists I’ve created and keeps products I purchase under the “Bought Often” tab, which is automatically updated monthly.

The Quick Tools feature is a shortcut that makes it easy for trade professionals to quickly access other popular site features. It gives me the quick ability to order, reorder, find an order, or turn existing quotes into orders, all in one place. In some cases, I can even order online and have the order ready in an hour with Pro Pick-Up 1 Hour (at locations where Pro Pick-Up 1 Hour is available).

While traditional brick-and-mortar purchasing is still a viable wholesale solution, with Ferguson.com, I can gain access to a seamless and convenient online ordering system. This allows me to browse through products, check availability, compare prices, and place orders anytime, from anywhere. By simplifying the procurement process, Ferguson.com saves valuable time and effort, enabling me to focus on serving my customers better.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Sometimes I need to know what was on an order or the last time I bought a certain product. I’m able to find all of that online and end any confusion about my orders. If I need to see the status of an order, I can see it on my Ferguson Dashboard or Orders, and even get the proof of delivery. (Proof of delivery may not be available depending on how the order shipped or if it was signed for.)

Forward Thinking

Ferguson understands the importance of competitive pricing for plumbing contractors. By signing up for a Ferguson.com account, one can unlock access to exclusive contractor pricing on a wide range of products. This ensures that I can offer my customers competitive rates while maintaining healthy profit margins for my business. The savings one can achieve through Ferguson.com can significantly impact your bottom line and give you a competitive edge in the market.

It’s pretty simple, really. Creating an account on Ferguson.com provides plumbing contractors with a range of powerful tools to manage their business efficiently. By logging in, one can track his or her order history, access invoices, and manage one’s account settings, all in one centralized location. This streamlined account management feature eliminates the need for tedious paperwork and enables one to stay organized and in control.

What’s also cool about the site is that I can enroll for the free PRO Plus™ program. After I enrolled in this program, I now earn one point for every dollar I spent online. I can then redeem those points for cool prizes and earn Bonus Points faster by purchasing featured products. PRO Plus™ customers are also eligible for discounts with select businesses.

Ferguson.com boasts an extensive inventory of plumbing products, tools, and supplies, as well as expert advice and efficient account management, making it a one-stop solution for all of my business needs. By utilizing the features and capabilities of Ferguson.com, I can streamline my operations, relieve operational stress, and propel my business toward greater success. Sign up today and unlock a world of opportunities for your plumbing contracting business with Ferguson.com.

The new course is part of the Counter Intelligence training series, designed to provide distributor employees with knowledge and skills to grow sales and build strong customer relationships Business Development Resources (BDR), a trusted provider of business coaching and training services for the HVAC, plumbing, and electrical industries, announces HVAC 101 for the Counter, a new live virtual course Read more

The new course is part of the Counter Intelligence training series, designed to provide distributor employees with knowledge and skills to grow sales and build strong customer relationships

Business Development Resources (BDR), a trusted provider of business coaching and training services for the HVAC, plumbing, and electrical industries, announces HVAC 101 for the Counter, a new live virtual course series that empowers HVAC distributor counter teams with essential knowledge to improve customer service, efficiency, and revenue generation.

“Your parts counter team must have a foundational understanding of the products you sell and how they work,” said Matt MacArthur, BDR’s Director of Training. “This allows them to deliver a higher level of customer service and efficiency, which leads to increased average tickets and greater customer satisfaction and loyalty.”

BDR announces HVAC 101 for the Counter, a new live virtual course series that empowers HVAC distributor counter teams with essential knowledge to improve customer service, efficiency, and revenue generation.

HVAC 101 for the Counter, scheduled for three sessions in October and November, gives attendees an overview of different types of HVAC equipment and their components, including gas furnaces, heat pumps, air conditioners, and ductless units. In the sessions, attendees will learn why it’s important to know HVAC systems and their components and how they work and operate, the different components and accessories available for each type of system, and communication skills for interacting with customers at the counter.

HVAC 101 for the Counter is presented in three two-hour sessions so teams can train without being pulled off the counter for an entire day. The sessions include:

- Gas furnaces, components, and accessories (Oct. 12)

- Heat pump and air conditioner components and accessories (Oct. 26)

- Ductless heat pumps, components, and accessories (Nov. 9)

HVAC 101 for the Counter is part of the ongoing Counter Intelligence training series, designed to provide distribution parts counter and inside sales employees with the knowledge and skills they need to succeed by growing sales and building stronger customer relationships.

To learn more about BDR’s HVAC 101 for the Counter training course, visit https://www.bdrco.com/event/counter-intelligence-hvac-101-for-the-counter/.

Prestigious award celebrates Peterman Brothers president and other ambitious entrepreneurs who are building a better world Ernst & Young LLP (EY US) today announced that Chad Peterman, president of Peterman Brothers, a leading HVAC and plumbing company serving the greater Indianapolis area, was named an Entrepreneur Of The Year® 2023 Midwest Award winner. The Entrepreneur Of Read more

Prestigious award celebrates Peterman Brothers president and other ambitious entrepreneurs who are building a better world

Ernst & Young LLP (EY US) today announced that Chad Peterman, president of Peterman Brothers, a leading HVAC and plumbing company serving the greater Indianapolis area, was named an Entrepreneur Of The Year® 2023 Midwest Award winner.

The Entrepreneur Of The Year Awards program is one of the preeminent competitive awards for entrepreneurs and leaders of high-growth companies. Peterman was selected by an independent judging panel made up of previous award winners, leading CEOs, investors and other regional business leaders. The candidates were evaluated based on their demonstration of building long-term value through entrepreneurial spirit, purpose, growth and impact, among other core contributions and attributes.

The Entrepreneur Of The Year Awards program is one of the preeminent competitive awards for entrepreneurs and leaders of high-growth companies. Peterman was selected by an independent judging panel made up of previous award winners, leading CEOs, investors and other regional business leaders. The candidates were evaluated based on their demonstration of building long-term value through entrepreneurial spirit, purpose, growth and impact, among other core contributions and attributes.

“This award is a testament to the foundation my father built at Peterman and the drive he instilled in my brother and me to always keep reaching for the next level,” Peterman said. “I’ve dedicated my life to serving this company, my community and the skilled trades. To be named Entrepreneur Of The Year is just an incredible honor.”

The award is the latest accolade given to Peterman and his company in recent years. In May, the Indianapolis Business Journal recognized Peterman Brothers as one of the 25 fastest-growing companies in Indianapolis for a fourth consecutive year. In 2022, Peterman Brothers landed a place on the Inc. 5000 for the fourth year in a row, and in 2021, the company was named Dealer of the Year by Bryant Heating & Cooling Systems, a leading supplier of HVAC equipment with more than 40,000 dealers in North America.

Peterman is also the founder of Peterman Top Tech Academy, whose latest class graduated earlier this month. In addition, he’s the host and creator of the Can’t Stop the Growth podcast, which is geared toward empowering leaders and helping business owners thrive and grow their company.

“Peterman Brothers has come a long way since its inception in 1986,” Peterman said. “We’re continuing to seek ways to better serve the community, including creating the Peterman Cares program to help those less fortunate. I’ve been blessed with an amazing team that has driven our expansion to six locations, and winning this award says as much about my staff and support system as it does about me.”

For nearly four decades, EY US has honored entrepreneurs whose ambition, courage and ingenuity have driven their companies’ success, transformed their industries and made a positive impact on their communities. Since 1986, the Entrepreneur Of The Year program has recognized more than 11,000 US executives.

As a Midwest award winner, Peterman is now eligible for consideration for the Entrepreneur Of The Year 2023 National Awards. The National Award winners, including the Entrepreneur Of The Year National Overall Award winner, will be announced in November at the Strategic Growth Forum®, one of the nation’s most prestigious gatherings of high-growth, market-leading companies.

Peterman Brothers is available to help with any plumbing or cooling needs. For more information, call (260) 201-3070 or visit www.petermanhvac.com.

Do you have big plans for your plumbing business? Are you ready to take your company to the next level? If so, you may have been considering expanding your company. Growing your plumbing business is the ideal way to take it to the next level of success, and now is a great time to do Read more

Do you have big plans for your plumbing business? Are you ready to take your company to the next level? If so, you may have been considering expanding your company. Growing your plumbing business is the ideal way to take it to the next level of success, and now is a great time to do it. Right now, the demand for plumbers is high. According to a recent HBI Construction Labor Market Report, there is a 55% shortage of plumbers that are available to work.

The shortage of plumbers provides you with the ideal opportunity to capitalize on this increased demand for your services. But, even when demand is high for your services, choosing to expand your business is still a big decision to make.

Taking steps to grow your business is always something that should be done carefully. Diving straight into scaling your business and investing significant amounts of money and resources to facilitate the expansion can be a costly error to make.

Putting too much of your time, money, and effort into growing your company can jeopardize your entire business and put everything you have worked so hard for at risk. To protect your business and to reduce the risks associated with expansion, it is crucial to take a measured approach. Read on to discover essential tips to help you successfully expand your plumbing business and help your company to reach its full potential.

Carry Out Extensive Research

Finding ways to reduce the risk of expanding your business is always crucial. Doing all that you can to protect your company as it is right now is essential. Otherwise, you risk sacrificing everything that you have worked for up to this point.

One of the best ways to reduce the risks involved in expanding your business is to carry out extensive research. Treating your expansion plans in the same way that you would a new business can be helpful. This means carrying out lots of research to familiarize yourself with competing businesses and the services that they offer. This will give you a far clearer idea of the types of services your business should offer if you want to compete directly.

Make a Plan

Taking a look through all the research that you have gathered together should mean that you now have a huge body of information that you can use to inform your expansion decisions. All of this research information may seem a little overwhelming to start with, but it is worth taking your time to work through it all, as it is the perfect way to understand who your competitors will be and how you can rival them successfully.

Working your way through all your research to build your knowledge is also the ideal way to identify any gaps in the market that your newly-expanded business will be able to fill. Based on all this information, you will be able to write a thorough business plan that details your expansion plans. Your business plan will provide to be vital in the weeks and months ahead, as you can keep referring back to it to ensure your progress stays on track.

Explore Opportunities

When you decide to expand your business, a whole host of opportunities will open up to you. You will be able to reach a whole new section of clients and even have the capability to offer specialist services based on your team’s expertise. Once you start to look for new opportunities, you will soon find that there are lots of options to explore in your quest to grow your business.

When you are just starting out on your journey into expansion, it is essential to keep your cash flow in mind at all times. Keeping your cash flow healthy is vital when expanding your business. Many companies make the mistake of stretching their finances too far during their growth phase, which means that they put their businesses under unsustainable levels of pressure. To overcome this, you may want to seek out contracts that offer your company repeat business to help your business to expand successfully while also maintaining a healthy cash flow. Pitching your business in the commercial sector is the best way to do this. Securing a contract to take care of all of a business’s plumbing needs and ongoing maintenance is an excellent way to receive a steady income for your business. As your team and your reputation continue to grow, you should find you attract more ongoing clients.

Invest in Software

While your business may have been successfully operating for a while now, it is essential to remember that the way you run it will need to change as it grows. More employees and an increase in jobs mean that it will be much harder to keep track of what is happening in your business on a daily basis. However, as your business grows, it becomes more important than ever before for it to stay organized and for you to keep track of what is happening both on a day-to-day level and at an operational level.

When you have employees going off to jobs in many different locations throughout the day, it can be an ongoing challenge to try and keep track of where they are and what job they are currently working on. But knowing this information is vital if you are to offer your customers the very best service and to keep your business running efficiently.

Investing in the best field service management software will make running your business so much easier. You will be able to organize your team’s workload more efficiently while also ensuring that your customers get a far better service. Choosing software that offers live field updates will help you to monitor where your team members are at any one time. This is vital when you run a plumbing business and will help you to provide an emergency plumbing service to your customers and to get your team to them in the fastest possible time.

Interplay Learning, the leading provider of online skilled trades training, is pleased to announce a strategic partnership with Southern Home Services Corporation, a leading residential home services provider specializing in HVAC, plumbing, electrical, and generator service, replacement, and maintenance. This important collaboration names Interplay Learning the exclusive content engine for technical training and the designated LMS Read more

Interplay Learning, the leading provider of online skilled trades training, is pleased to announce a strategic partnership with Southern Home Services Corporation, a leading residential home services provider specializing in HVAC, plumbing, electrical, and generator service, replacement, and maintenance. This important collaboration names Interplay Learning the exclusive content engine for technical training and the designated LMS provider across Southern Home Services’ growing network of 25+ locations.

Recognizing the crucial need for a standardized technical training and development system across its expanding portfolio of companies, Southern Home Services Corporation aligned with Interplay Learning to deliver a unified and scalable training solution to their 750+ technicians. By leveraging Interplay’s cutting-edge digital learning platform, technicians at every business location will have seamless access to industry-leading training tools and resources, including immersive 3D simulations and virtual reality experiences.

Interplay’s diverse content catalog will ensure that technicians across various skill levels and trades can enhance their knowledge, acquire new skills, and earn essential career-building industry certifications like EPA 608. Further, the platform’s built-in skills assessment tool will play a vital role in identifying and addressing technicians’ skills gaps, providing targeted learning paths to bridge those gaps. The state-of-the-art training program will also assist Southern Home Services in improving recruitment, addressing labor shortages, reducing callbacks, and driving revenue growth throughout its extensive network.

Matt Ellenberg, Training Manager at Southern Home Services, emphasized the importance of Interplay’s training and development on company growth, stating, “Training equals next month’s, next quarter’s, and next year’s revenue dollars. This partnership with Interplay is an investment in our technicians’ career development and a driver of future revenue.”

Chief Operating Officer Drew Poskon adds, “This training partnership is a testament to our commitment to providing best-in-class training that directly translates to best-in-class home service experiences for our customers.”

The relationship between Southern Home Services Corporation and Interplay Learning marks a significant milestone in advancing technical education delivery throughout the trades. By leveraging leading technology and comprehensive training resources, both organizations are poised to shape the industry, ensuring continued growth and success for Southern Home Services and its dedicated workforce.

“Interplay is thrilled to work with Southern Home Services in setting a new benchmark for technical education across the trades,” said Doug Donovan, CEO of Interplay Learning. “We are honored to work alongside them to drive acquisition success and provide their expanding workforce with a centralized system of career-building tools necessary for sustainable growth.”