Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator. These circulators are available with cast iron or Read more

hydronics

Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

These circulators are available with cast iron or NSF/ANSI 61 & 372 certified stainless steel volutes, so they are ideal for closed-loop heating systems as well as domestic hot water recirculation systems. Both circulators also offer a convenient, rotatable control box cover for a professional look, no matter the orientation of the installed circulator.

The 0034e features an easy-to-use dial with five operating modes, including constant pressure, fixed speed, Taco’s exclusive activeADAPT™ self-adjusting proportional pressure, and 0-10V capability. The 0034ePlus adds proportional pressure and more constant pressure settings as well as a digital display with real-time feedback, including watts, GPM, feet of head, and RPM. Both circulators are dual-voltage 115V/230V.

Both new circulators come with exclusive features that make Taco’s ECM high-efficiency circulators so easy to use, including SureStart® automatic unblocking and air purging, BIO Barrier® black iron oxide protection, dual electrical knockouts, six-inch stranded leads, recessed flange nut-grabbers and double insulation so no ground wire is needed.

For more information, visit www.TacoComfort.com

The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Read more

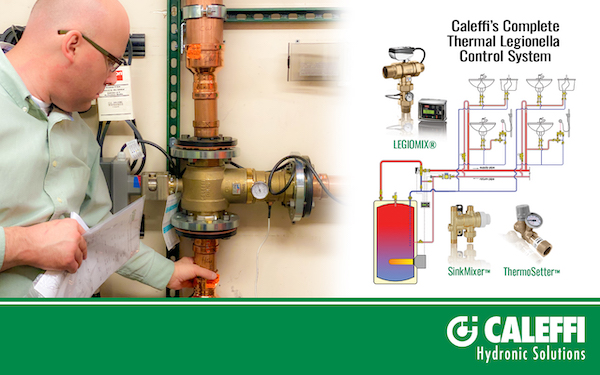

The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Legionella which can proliferate to dangerous concentrations.

Experienced water maintenance managers know susceptible systems should be flushed before reusing. Important considerations should not be overlooked such as ensuring all service lines are purged and dead legs drained.

Several factors determine if the system equipment requires treatment such as how long a system is left idle, the temperature of the stagnated water and condition of the internal surfaces. This is so bacteria that are resistant to simple purging/draining and have become resident in biofilm can be addressed. Common methods include thermal treatment or treating with chemicals such as chlorine, chlorinated gas and chlorine dioxide.

A significant benefit of thermal treatment is that it’s a proven, cost-effective method for bacteria management on an ongoing basis in the hot side of the plumbing system. The cold side doesn’t typically require ongoing treatment unless water remains stagnated for extended periods within the temperature range that Legionella grows which is 68°F to 122°F.

Thermal treatment requires little additional maintenance compared to chemical treatment. Also, common plumbing equipment such as seals, gaskets and polymer components are not exposed to potentially incompatible life-shortening chemicals.

Residual chemicals in the water can also be a human health concern if acceptable concentration values are exceeded. In contrast, most common plumbing materials can withstand, without effect, thermal shock temperatures such as 160°F.

Thermal treatment consists of periodically circulating elevated water temperature such as 160°F through the entire system for a specific and measured period of time, thereby killing harmful bacteria and restoring the water to a safe and usable condition. During this period it is important to ensure all point-of-use fixtures are either disabled for access or equipped with anti-scald devices. An example is the Caleffi scald-protection valve SinkMixerTM — an innovative, easy to install valve for under-sink applications.

Often the most difficult portions of the hot water side to circulate sufficiently through is the recirculation return risers. This because they are sized and balanced to a relatively low flow rate such as 0.5 GPM. The Caleffi ThermoSetterTM thermal balancing valve automatically responds when it senses high temperature water by fully opening an internal by-pass, thereby allowing a sufficient return riser flushing during treatment. It then automatically returns to standard operation state when water temperature decreases to normal.

If a building is equipped with a Caleffi LEGIOMIX digital mixing valve, it will enjoy highly accurate mixed water temperature 24/7. The LEGIOMIX has industry-unique, calendar- based automatic thermal disinfection programs. For thermal monitoring, it has data logging capabilities and can connect to a building automation system for remote monitoring and access.

LEGIOMIX combined with SinkMixer anti-scald valves and ThermoSetter recirculation balancing valves offer an innovative total thermal solution for control of safe and sanitary domestic hot water.

Lindon, Utah —Aquatherm, the industry leader in polypropylene piping systems, has released an informative new video that provides an overview of polypropylene pipe applications and benefits, as well as the company’s expertise and capabilities. The “Leading the Way in Polypropylene Piping” video includes information about the advantages of polypropylene pipe over steel pipe for commercial Read more

Lindon, Utah —Aquatherm, the industry leader in polypropylene piping systems, has released an informative new video that provides an overview of polypropylene pipe applications and benefits, as well as the company’s expertise and capabilities.

The “Leading the Way in Polypropylene Piping” video includes information about the advantages of polypropylene pipe over steel pipe for commercial heating and cooling systems, industrial piping, and domestic water systems. The video explains how polypropylene repels water and will never scale or corrode the way metal pipe does, thus ensuring the quality and integrity of mechanical systems and potable water systems.

The video also explains the heat fusion process that joins polypropylene pipe and fittings, and how heat fusion creates a connection that’s as strong or stronger than an as-manufactured section of pipe—with no leak paths.

Also covered are Aquatherm’s Fabrication Services and Scan-to-Fab, both of which can help simplify and compress the timeline of complex projects as well as provide labor savings.

A quick jobsite visit to the western suburbs of Chicago found hydronics guru Alan Carlson (Instagram @alan_carlson) swapping out leaking boilers at an 80-unit apartment complex. Carlson, a plumbing and heating industry veteran has been repping the trades for the past 19 years. He entered the plumbing trade back in 2001, and for the past Read more

A quick jobsite visit to the western suburbs of Chicago found hydronics guru Alan Carlson (Instagram @alan_carlson) swapping out leaking boilers at an 80-unit apartment complex.

Carlson, a plumbing and heating industry veteran has been repping the trades for the past 19 years. He entered the plumbing trade back in 2001, and for the past few years now, he has moved over to the hydronics side of the job with Ambrust Plumbing & Heating Solutions, Carol Stream, Ill., to where—back in 2014—he took his plumbing skills. Since 1918, Armbrust has provided DuPage County residents exceptional residential/commercial plumbing and heating services.

Carlson is testament to hard work and dedication to his craft. “I knew I wasn’t cut out for college and the trades has afforded me the opportunity to make a good living and provide for my family,” says Carlson.

Alan takes great pride in his work and it shows with the finished product. “I am a hard-working, goal-oriented person who specializes in problem solving, job quality and customer satisfaction.”

And don’t take his word for it, read what customers are saying about Alan and his professionalism. According to an online review, “This is the second time I have had Alan C. over to check on our plumbing. He is always friendly and very knowledgeable. He has a considerable level of experience and he has been able to answer all of my questions. When presented with options for needed services, he is honest in giving feedback with absolutely no pressure. Armbrust is a great plumbing company.”

And don’t take his word for it, read what customers are saying about Alan and his professionalism. According to an online review, “This is the second time I have had Alan C. over to check on our plumbing. He is always friendly and very knowledgeable. He has a considerable level of experience and he has been able to answer all of my questions. When presented with options for needed services, he is honest in giving feedback with absolutely no pressure. Armbrust is a great plumbing company.”

Carlson was introduced to the trades at a very early age because his great grandfather, C.J. Erickson, started one of the oldest, and still one of the most successful, plumbing businesses in Chicago. In 1906, Carl Joseph “Joe” Erickson immigrated to America from Sweden, settling in Chicago. Joe, an accomplished plumber, signed with Plumbers Local 130 and set out to live the American dream, opening his own shop.

Although Carlson never worked at his great grandfather’s shop in the city, he got a taste early in his youth of what working in the trades would be like. “I didn’t know what career I wanted after high school. I tried the local junior college without any direction, hoping I would magically find something. I didn’t even finish a year. I decided that if my family can run a successful plumbing company in Chicago for four generations, and if my neighbor who owns his own company can make a good living, I would try plumbing,” says Carlson.

The trades have enriched Carlson’s life because he now possesses important and highly desired skills. “I also have a better understanding and much higher respect for those who work physically hard to earn their wage,” says Carlson.

Carlson stresses that there never should be a negative stereotype attached to being in the trades. “Having a career in the trades does not mean that you’re dumb or dirty or should be looked down upon. A trade is a highly skilled and highly needed job. If you want to have a career where you will always be needed, regardless of the economy, become a plumber. And if you do decide to get into it, work hard, never stop learning and never stop asking questions; be the first one there and the last one to leave,” says Carlson.

Irvine, Calif. — Navien, Inc., the leader in condensing technology, will establish its first U.S. manufacturing and assembly operation in James City County, Va. The 300,000-sq.-ft. facility will be used as a distribution center for the first two years and begin the transition process & preparation into manufacturing operation in 2022 with the first stage of manufacturing Read more

Irvine, Calif. — Navien, Inc., the leader in condensing technology, will establish its first U.S. manufacturing and assembly operation in James City County, Va. The 300,000-sq.-ft. facility will be used as a distribution center for the first two years and begin the transition process & preparation into manufacturing operation in 2022 with the first stage of manufacturing expected to begin in 2023.

“Navien’s decision to locate its first U.S. manufacturing operation in James City County demonstrates the competitive advantage that Virginia offers to international companies looking to expand into new markets,” said Virginia Governor, Ralph Northam. “This project is an important win for the Greater Williamsburg region and our Commonwealth, as Navien will bring a key facility back into productive use, create 180 high-quality jobs, and utilize the nearby Port of Virginia as its gateway to the world.”

Contingent upon regulatory permits and approvals, Navien’s current plans are to expand the existing facility starting in 2023, which will triple the footprint to nearly 900,000 sq. ft. by 2026.

“The close proximity of this property to the Port of Virginia and the flexibility to expand and allow for Navien’s continued investment over time helped us make this decision,” said Navien CEO Sangkyu Lee. “Establishing an East Coast facility will support Navien’s growth and allow for faster delivery to primary eastern markets while balancing current shipments coming into California. We look forward to working with the Virginia Talent Accelerator Program as we grow this facility and its importance to Navien’s overall leadership position in North America.”

Distribution of Navien products from the new Virginia facility is slated to begin in April 2020.