https://youtu.be/uN4-f1acm3w Caleffi is STOCKED and LOADED. We have the plumbing and hydronic products you need including PRVs, TMVs, relay controls, separators, zone valves and more. Caleffi production and warehouse staff remain healthy. We are busier than ever thanks to our loyal customers. And our lead-times have never been better! Bring it on. Caleffi Guaranteed. Click Read more

hydronics

Caleffi is STOCKED and LOADED.

We have the plumbing and hydronic products you need including PRVs, TMVs, relay controls, separators, zone valves and more. Caleffi production and warehouse staff remain healthy. We are busier than ever thanks to our loyal customers. And our lead-times have never been better!

Bring it on. Caleffi Guaranteed.

Click here for more information!

Seminar attendees can earn credits and certifications. Broomfield, Colo. — Viega LLC is adding more classes to its schedule of online seminars for contractors who want to increase their knowledge and add skills. While Viega’s seminar centers in Colorado and New Hampshire are temporarily closed due to COVID-19, the company is making the valuable training Read more

Seminar attendees can earn credits and certifications.

Broomfield, Colo. — Viega LLC is adding more classes to its schedule of online seminars for contractors who want to increase their knowledge and add skills.

While Viega’s seminar centers in Colorado and New Hampshire are temporarily closed due to COVID-19, the company is making the valuable training available for free to contractors, distributors and others.

While Viega’s seminar centers in Colorado and New Hampshire are temporarily closed due to COVID-19, the company is making the valuable training available for free to contractors, distributors and others.

Viega, the leading manufacturer of pipe fitting installation technology, is offering classes in such subjects as ProPress, MegaPress and PureFlow PEX, as well as radiant and flushing systems training. The classes are taught by Viega’s expert instructors. Some courses offer Continuing Education Units while others include the opportunity to earn industry credentials from Viega.

Classes are free, but registration is required. For a schedule of Viega classes and to learn more, click here.

In addition, Viega is continuing its “TechTalk LIVE!” program. Master plumbers and Viega training managers Troy Locke and

Bo DeAngelo will discuss technical topics and answer questions from viewers in realtime.

The next webinar is Wed., Aug. 26 from 5 to 6 p.m. CT. Previous sessions are available on Viega’s YouTube channel.

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service. Features of the new design include full opening integral union ends, bi-directional condensate flow, ¾” Female NPT inlet/outlet tappings and ¾” Read more

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service.

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service.

Features of the new design include full opening integral union ends, bi-directional condensate flow, ¾” Female NPT inlet/outlet tappings and ¾” male NPT x socket fittings. The unit also comes with snap-in mounting brackets included.

The redesigned CN4B-600C, CN4B-850C, CN4B-1200C, CN4B-2000C four-inch neutralizers are designed to facilitate the use of Neutra-Safe’s proprietary media sacks for simple recharging of the unit. This Neutra-pH media blend is a blend of blend of 99 percent pure calcite and magnesium oxide, provides the most efficient neutralization possible. It eliminates clumps that can clog traditional neutralizers. The sack can be opened to release the media for use in Neutra-Safe’s older four-inch tube models.

The best features of the original four-inch neutralizer remain, including a clear tube for easy visual inspection and patented integral union ends with O-ring seals for a leak-proof connection.

Neutra-Safe’s tube style condensate neutralizer line includes seven models, serving high-efficiency, gas-fired appliances up to 2 million BTUH input capacity.

For more info, www.NeutraSafe.com.

A new life. Nicholas Verkhoturtsev’s story starts in his hometown of Ural—everybody calls it Siberia—Russia. In 2002, Nicholas graduated from Law State University with a Bachelor’s degree. That same year, a company Nicholas worked for as a lawyer, purchased a plumbing company and Nicholas became co-owner of that company. Teaching law at the University and Read more

A new life.

Nicholas Verkhoturtsev’s story starts in his hometown of Ural—everybody calls it Siberia—Russia. In 2002, Nicholas graduated from Law State University with a Bachelor’s degree. That same year, a company Nicholas worked for as a lawyer, purchased a plumbing company and Nicholas became co-owner of that company.

Teaching law at the University and working on his Master’s degree seemed to be the career path he set for himself. “I didn’t do anything in that plumbing company; I just controlled its finances, but I paid attention and learned their work, skills and knowledge,” says Nicholas.

In the meantime, with increasing corruption in Russia, Nicholas became disenchanted and bored with law so he turned to plumbing. “I got interested in plumbing because I liked it as a field where everything depended on my skills and knowledge, not on other people—judges, prosecutors, government people etc.—or how much money I bring them under the table. Yes, I would make more money if I stayed in law, but I fell in love with plumbing because of that independence,” says Nicholas.

He created a plumbing company and hired the guys from the company he controlled previously. “I continued to learn their plumbing skills and did all paper work and management of operations. In 2003-2004, I started to do all work myself and fired the guys who worked for me. Most of my jobs in Russia was residential, but I did some big projects such as a water park—the radiant heating system with mixing and pump units, used 18 miles of PEX pipe—an auto dealership—radiant heating system with climate control, for example,” says Nicholas.

Nicholas soon realized that growing and developing his plumbing business looked grim, and any outlook for making his family’s life better looked increasingly bleak, “because of huge corruption, a sputtering economy and terrible politics by fucking Putin and his people,” says Nicholas.

Nicholas soon realized that growing and developing his plumbing business looked grim, and any outlook for making his family’s life better looked increasingly bleak, “because of huge corruption, a sputtering economy and terrible politics by fucking Putin and his people,” says Nicholas.

What was supposed to be a planned vacation to the United States turned out to be a lifetime commitment. “I tried to change things by becoming a peaceful political protester in my home city, but with very bad results. I ultimately decided to move to the U.S., got all of the necessary documents, and did it.”

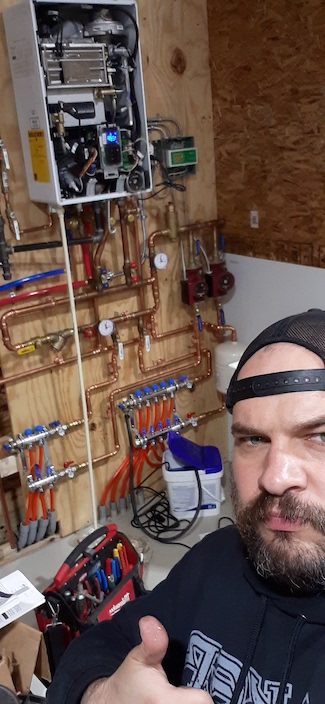

Upon arriving in the United States, Nicholas worked for David Hesson, and for the past five weeks has been working for Robbie Mann at A. Mann Plumbing LTD, Centerburg, Ohio, as a tech for residential and commercial plumbing and hydronic heating systems, service plumbing and drain cleaning. “I am very happy to be a part of their team,” says Nicholas.

Upon arriving in the United States, Nicholas worked for David Hesson, and for the past five weeks has been working for Robbie Mann at A. Mann Plumbing LTD, Centerburg, Ohio, as a tech for residential and commercial plumbing and hydronic heating systems, service plumbing and drain cleaning. “I am very happy to be a part of their team,” says Nicholas.

While growing in the trades and starting his own plumbing business in Russia, Nicholas didn’t have any mentors, really. But, according to Nicholas, “I would call Eric Aune a friend and mentor; I learned a lot from him on Instagram while I worked in Russia.”

Now in the states he’s learned from Hesson, and his current teachers and mentors, Robbie Mann and Mark Starkey. “Every hour, every minute when I work with them I gain knowledge and skills. And, they always answer my stupid questions,” jokes Nicholas.

The Next Generation

Nicholas does express concern about the future of the trades. “I don’t see many young people who are ready to grow and learn things in plumbing, here is the USA and Russia.” And, from what Nicholas has seen is that plumbing in America is always growing. The importance of the trades has never been more evident than in these uncertain times of the pandemic. “After fucking Covid starts, we are getting more service calls. Covid just proves plumbing is as necessary ever,” says Nicholas.

“We all need to reach to people, young people and make them able to realize that plumbing is an essential job, a necessary job, and that people can’t live without water, heating and waste management.”

“We all need to reach to people, young people and make them able to realize that plumbing is an essential job, a necessary job, and that people can’t live without water, heating and waste management.”

Nicholas’s advice to those entering the trades? “Learn everything yourself; learn more than you should know. When you start to work in plumbing, do more than you should do and don’t wait for someone to give you skills and knowledge. Just get all this yourself.”

Me Time, Social Media

In his spare time Nicholas continues to learn plumbing, and he reads American plumbing codes. As well I do some exercises on my knees and back. That is what plumbers need. And, according to Nicholas, balancing family/work life is sharing every concern, every thought, every action about your work with your spouse. Your family should know every detail of your work life. “In my opinion, it helps find necessary time for your family.”

Social media has been instrumental in Nicholas’s growth, as well. He has found many of his current friends in the states on the social media platform. “A couple of my best friends from Instagram are Eric Aune and my boss Robbie Mann. Eric has always supported me, and when I arrived in the U.S., he sent me a bunch of tools which I’m still been using every day,” says Nicholas (@installer.nicholas). “I think Instagram is the best network to share work, knowledge and skills. And sharing these things is a way to find people who understand you totally.”

Social media has been instrumental in Nicholas’s growth, as well. He has found many of his current friends in the states on the social media platform. “A couple of my best friends from Instagram are Eric Aune and my boss Robbie Mann. Eric has always supported me, and when I arrived in the U.S., he sent me a bunch of tools which I’m still been using every day,” says Nicholas (@installer.nicholas). “I think Instagram is the best network to share work, knowledge and skills. And sharing these things is a way to find people who understand you totally.”

The last time Nicholas said, “Today is a great day”? It’s hard to say, says Nicholas. “In plumbing I enjoy results done perfectly; when everything is perfect, especially systems water flow and efficiency. Sometimes I even lose time/money to get something perfect, but I do it to enjoy the result … to enjoy my life, finally.

Earning a Bachelor of Arts in Criminal Justice, Michael Flynn’s (@flynnstone1) career path took an unexpected turn. “I fell ass-backward into the trade,” says Flynn. Early on, Flynn worked as pool lifeguard for six years, and, at the time, he knew a family that owned a plumbing and HVAC business. “They asked me to come Read more

Earning a Bachelor of Arts in Criminal Justice, Michael Flynn’s (@flynnstone1) career path took an unexpected turn. “I fell ass-backward into the trade,” says Flynn. Early on, Flynn worked as pool lifeguard for six years, and, at the time, he knew a family that owned a plumbing and HVAC business. “They asked me to come on as a helper and driver, and they said I could go on my interviews and take care of my criminal justice stuff any time I needed.”

After realizing that he wasn’t getting hired due to the job shortage in 2008, Flynn focused all of his energy on the trade; he started paying more attention because this was his new career path.

When the guy Flynn was driving for left that company a year and a half later, Flynn’s boss at the time threw him the keys and told him to hop in the truck. “Needless to say, I was shaking in my boots. I was super nervous to run my own truck and service calls. Yet the boss told me to call him anytime I needed help to describe what I was looking at. The dude was a genius; he helped me fix it every time, and this was before FaceTime and good quality phone pictures, lol,” says Flynn.

With this new-found confidence instilled by his boss, it finally clicked in Flynn’s head that he could succeed in the field. Then, a self-inflicted roadblock. Flynn got a DUI and the company couldn’t keep him on, which inevitably led him on the path to sobriety. “I’m going to be four years sober on the 19th of this month,” says Flynn.

With this new-found confidence instilled by his boss, it finally clicked in Flynn’s head that he could succeed in the field. Then, a self-inflicted roadblock. Flynn got a DUI and the company couldn’t keep him on, which inevitably led him on the path to sobriety. “I’m going to be four years sober on the 19th of this month,” says Flynn.

Searching for new work, he worked for a company for six months and eventually moved to another company. “That company’s boss taught me a lot about the business aspect of the trade, and he was super hard on me to succeed. Because of that, I did 1/2 million in sales for him on the service side in one year.”

Eventually, Flynn sought an opportunity to advance his career and he moved to the company he is at now, Service Professionals, Union, New Jersey, to do installs. Working with Service Professionals for the past six years, Flynn wears many hats and has multiple responsibilities. “I am a lead installer for residential installations for plumbing and boiler service, and I oversee all operations on the jobsite, and entire projects. I’m also a field supervisor, and take care of warranty issues, difficult service calls, and sometimes oversee other installs that I am not even a part of,” says Flynn.

Eventually, Flynn sought an opportunity to advance his career and he moved to the company he is at now, Service Professionals, Union, New Jersey, to do installs. Working with Service Professionals for the past six years, Flynn wears many hats and has multiple responsibilities. “I am a lead installer for residential installations for plumbing and boiler service, and I oversee all operations on the jobsite, and entire projects. I’m also a field supervisor, and take care of warranty issues, difficult service calls, and sometimes oversee other installs that I am not even a part of,” says Flynn.

The last few months have been rather difficult, but lately business has picked back up. When COVID-19 first started here in the states, work was extremely slow, says Flynn. The company had to lay off a few installers—some who weren’t comfortable coming into work and some that just wanted to take off. “It was rough; fighting to get 25-30 hours a week when I’m normally at 50-60. People wouldn’t let us in the house. Now it has picked up because the weather is getting warmer and people need their AC. We are wearing masks and gloves, and asking customer to keep their distance when we are performing an install.”

Flynn owes much of his growth and success to his father. “I’m adopted, which can be tough for some people. He showed me the meaning of hard work, but most of all, he showed me the love and affection I needed,” says Flynn. “He told me that if I wanted something, I had to put in the work to get it, and I still carry that to this day.”

Flynn owes much of his growth and success to his father. “I’m adopted, which can be tough for some people. He showed me the meaning of hard work, but most of all, he showed me the love and affection I needed,” says Flynn. “He told me that if I wanted something, I had to put in the work to get it, and I still carry that to this day.”

That hard work translates to happy customers. “I get the best feeling when a customer sees the finished install and says ‘wow’! Taking a really bad looking and terribly functioning system and turning it into gold is what I live for,” says Flynn.

Beast mode

Flynn’s advice to those considering the trades is to dive head first into the trade and don’t be afraid to ask questions. “The lead, boss, or owner knows a lot more than you will ever know. That doesn’t mean they are not willing to teach you what they know. Are a hands-on learner or a watch and learner? It helps so they can get you to a point where you can perform tasks on your own,” says Flynn.

While the job is very rewarding, it’s not all puppy dogs and rainbows. “It’s a rough and tough industry. You have to lift stuff, push stuff and pull stuff; that’s just the nature of the beast. But, it’s also extremely fun. We have a great time every day, whether it’s joking on the job site—while still getting work done—or problem solving in a customer’s home. It really is a great place to be.”

The RIDGID Rp241 propress tool is one of Flynn’s go-to tools.

Yet, people have to know that the trade and industry is always changing, says Flynn. “My concern is people’s unwillingness to change with it and adapt. Some things never change. But some things are completely different. You have to look at things totally different now and be able to adapt. There is a lot of technology that can help people improve system performance, for example.”

According to Flynn, that excitement and visibility for the trades needs to start with shop classes in middle school and high school. For instance, recently Flynn was cleaning out his basement and found some woodworking projects he did in middle school. “I said to my wife, ‘Damn, I wish they had shop in high school.’ I might have been even further in my career if they did,” says Flynn.

Being part of the RIDGID Experience was one of the best things in Flynn’s career

Moreover, the trades need to more in the discussion as a viable option. “Everyone is pushing college, college, college when you can go to trade school and be debt-free. Don’t get me wrong, I benefited from college as far as knowledge and people skills, but I am not using that degree.”

Finding success in the trades does take time, hard work and dedication. And finding the right balance between home and work life can be difficult. “Balancing is hard, but it’s great for me because when I’m home, I’m home. I don’t have to go out. No on-call for me at all. There is an install weekend rotation, but that’s it. My wife knows that I am working very hard to provide so she doesn’t give me a hard time. If I know it’s going to be a long day, I let her know beforehand. She really is a great support for me. Communication is key to that, as well,” says Flynn.

In what spare time he has, Flynn enjoys reading and researching, BBQs and cookouts with family and friends, concerts and fishing trips. That researching includes scrolling through IG and absorbing as much information as he can. Social media has been a beneficial frontier for Flynn. “IG has been great for me. Connecting with everyone in the trades is incredible, and it really has helped me up my game on install with cleanliness and functionality. All of the tips and tricks is amazing.

In what spare time he has, Flynn enjoys reading and researching, BBQs and cookouts with family and friends, concerts and fishing trips. That researching includes scrolling through IG and absorbing as much information as he can. Social media has been a beneficial frontier for Flynn. “IG has been great for me. Connecting with everyone in the trades is incredible, and it really has helped me up my game on install with cleanliness and functionality. All of the tips and tricks is amazing.

I’ve also made some contacts with some tool companies, which is cool. Obviously, being part of the RIDGID Experience was one of the best things in my career, and I found out about that through Mechanical Hub!” says Flynn.

The last time Flynn said it was a great day? “It may sound cheesy, but every time I step back and look at a completed job that is running perfectly, I have a good day. I really do love what I do.”