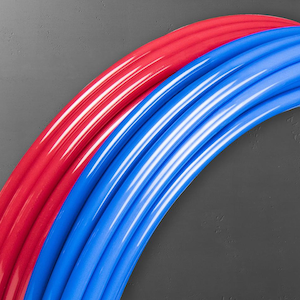

When you need a durable, reliable in-slab piping solution for your plumbing projects, look to pre-sleeved Uponor AquaPEX®. Pre-sleeved Uponor AquaPEX in-slab plumbing systems require shorter pipe runs for less material, less water volume, less energy, better hot-water delivery times and less water consumption. With its color-coded red or blue HDPE sleeving around strong, durable Read more

PEX piping

When you need a durable, reliable in-slab piping solution for your plumbing projects, look to pre-sleeved Uponor AquaPEX®. Pre-sleeved Uponor AquaPEX in-slab plumbing systems require shorter pipe runs for less material, less water volume, less energy, better hot-water delivery times and less water consumption. With its color-coded red or blue HDPE sleeving around strong, durable PEX-a pipe, you have the fastest, easiest method for installing plumbing systems in the slab.

To learn more, visit the Uponor Online Product Catalog.

Recently, the Mechanical Hub team took part in a two-phase, two-state trip to visit Viega’s North American manufacturing in McPherson, Kansas, and toured the brand new HQ and Seminar Center in Broomfield, Colo. Impressive is the first thing that comes to mind when describing both facilities. The McPherson manufacturing facility exudes the company’s philosophy of Read more

The new Viega North American headquarters in Broomfield, Colo., was designed to look like a fitting.

Recently, the Mechanical Hub team took part in a two-phase, two-state trip to visit Viega’s North American manufacturing in McPherson, Kansas, and toured the brand new HQ and Seminar Center in Broomfield, Colo. Impressive is the first thing that comes to mind when describing both facilities.

One of the Viega manufacturing facilities in McPherson, Kansas.

The McPherson manufacturing facility exudes the company’s philosophy of both progress and vision for the future. “We are constantly looking past the immediate future and into the distant future,” Eric Wicker, director, manufacturing, Viega.

Eric Wicker, director, manufacturing, Viega

This summer, Viega completed a two-year building program in McPherson that included: a 90,000-sq. ft. expansion of a manufacturing plant, completed in Dec. 2017; a new 205,000-sq.-ft. manufacturing plant, completed in June; and a new 25,000-sq.-ft. tool shop and apprentice building, completed in July. And, the company is currently building a 55,000-sq.-ft. logistics expansion—a high-bay storage and retrieval area for inventory.

The manufacturing floor at the McPherson facility is as meticulous as it gets.

Mimicking some of the processes from its global HQ in Germany, robotics and machining take center stage throughout the meticulous McPherson plant. Fear not, all of this new-fangled technology is not taking jobs away, rather increasing them. Currently at approximately 300 employees, the company hopes to hit the 500 mark by years ’23-’24.

Some of the copper inventory, now produced in the states.

McPherson is where Viega produces its PureFlow line of PEX product, as well as select fittings from the ProPress Copper and 80,000 sq. ft. dedicated to its MegaPress product lines. McPherson is also home to Viega’s master distribution center for North America.

Continued expansion is a testament to the company’s progressive philosophy. For instance, the company has dedicated 270,000 sq. ft. to the copper fitting production. “The goal is to be producing the majority of copper fittings sold in the U.S. right here in the states,” says Wicker.

Plastic fittings rolling off the line. Seven million per month made in Kansas.

The state-of-the-art distribution center incorporates the latest technology and automation, as well as an upgraded warehouse management system that provides faster product turnaround. With additional metals products being manufactured in McPherson, a larger distribution center for both metals and PEX products was necessary.

Although media wasn’t allowed to shoot photography inside the plants—understandably—the tour started in the 36,000-sq.-ft. Plastic Injection Molding area which exemplified the company’s high investment in tooling. Twenty machines produce approximately seven million fittings per month. This particular building was well lit and comfortable, due, in part, by the implementation of its own radiant heating and cooling technology.

Quality is never understated at Viega; we strolled through the Quality Assurance Lab where dedicated staff monitor product and equipment through a series of rigorous testing.

The Broomfield Seminar Center

Next, we toured the 200,000-sq.-ft. Extrusion Area where the plastic piping is made. Once made and exported from Georgia, Viega now produces its own resin—which is transformed into pellets—onsite. The rejected pellets are not repurposed, yet recycled and sold.

Whoa! Check out the beautiful seminar center, and the frickin’ view!

There is a Special Extrusion Area where plastic metal plastic tubing extrusion is performed. The only company in America making this, the plastic piping is integrated with aluminum so it can better hold its shape rather than returning back to its original form. (Nearby is a 40,000-sq.-ft. dedicated machine shop.)

Another angle of the entrance to the seminar center with the HQ in the background.

We then toured the 270,000 sq. ft. of ProPress copper fittings production area and 80,000 sq. ft. of the MegaPress/Metals production area. Strategically, it makes sense for Viega to start producing here in the states. With press technology introduced here in 1999, education and awareness of the process and technology have helped contractors nationwide run a more efficient business. Viega system solutions are designed to work together in plumbing, heating, cooling and pipe joining applications, making the contractor’s work fast, easy and safe.

The seminar center features an interactive display area chock full of Viega products.

The following day we were flown to Denver to tour the recently opened Viega North American headquarters and Seminar Center in Broomfield, Colo. The 55,000-sq.-ft. headquarters resembles a pipe fitting, and its interior is the real testament to Viega innovation. I can’t express enough how beautiful these two buildings are, and, of course, amid the breathtaking backdrop of the Rocky Mountains. The HQ building opened in January and the first official training took place April 8, and weekly training is booking fast. “Viega is absolutely committed to its customers and their success in the field,” says Bo DeAngelo, manager, technical training at the center.

Like a proud new papa, Bo DeAngelo gives the tour of the new seminar center.

Yet, I am always interested: when a new facility is built, does it incorporate its own products? While the cross-laminated timber beams are imported from Austria, the exposed ceilings give employees and visitors a clear view of the many uses of Viega’s innovative technology.

We’ve located the custom Viega chopper! It was taken in the middle of the night from the McPherson facility and relocated to Broomfield where it sits proudly on display. Who has the keys?

Potable water is carried through copper pipes connected with ProPress fittings. The carbon steel fire sprinkler system is joined with MegaPress fittings. Radiant heating and cooling keeps the building comfortable, while a snowmelt system keeps the courtyard free of ice and snow. Manifolds ensure the systems operate smoothly and efficiently. The restrooms feature wall-hung bowls and no exposed tanks, thanks to in-wall carrier systems and Visign style flush plates.

The new 23,000-sq.-ft. Broomfield Seminar Center next door supplements Viega’s Nashua, New Hampshire Seminar Center, which has trained thousands of people since opening in 2006. The new center is an innovative training experience and is equipped with four classrooms, two hands-on labs, and interactive displays throughout, which allows attendees to see, touch and experience Viega products. “Demand for training has been increasing steadily. This facility will allow us to continue to provide and expand on the training that our industry deserves,” says CEO Dave Garlow.

Viega experts lead single- and multi-day classes in everything from radiant system design and fire protection to hydronics and pathogen prevention. Despite being open only since April, it is on track to host more than 2,100 students this year, says DeAngelo.

The Hub’s Eric Aune checks out the hydronics and snowmelt display.

I walked away very impressed, telling DeAngelo I—and I’m sure the clients that visit—can’t help but feel energized the minute I walk in this facility. Shaking his head in agreement, “That’s what Dave Garlow tells me every day he walks in here,” responded DeAngelo.

Make no mistake, there is a lot of money, time and resources invested in Viega North America. But it’s a huge testament to the dedication the company believes is its biggest investment: its customers and its employees.

The interactive display at the Broomfield Seminar Center features a breadth of innovative Viega products.

Viega PureFlow PEX pipe and fittings have been listed by Underwriter Laboratories (UL) as approved for use in exposed fire sprinkler systems in basements. The UL listings mean builders and contractors are now able to use PureFlow, Viega’s versatile system of PEX pipe and fittings, throughout an entire residential fire sprinkler system, said Seth Larson Read more

Viega PureFlow PEX pipe and fittings have been listed by Underwriter Laboratories (UL) as approved for use in exposed fire sprinkler systems in basements.

Viega PureFlow PEX pipe and fittings have been listed by Underwriter Laboratories (UL) as approved for use in exposed fire sprinkler systems in basements.

The UL listings mean builders and contractors are now able to use PureFlow, Viega’s versatile system of PEX pipe and fittings, throughout an entire residential fire sprinkler system, said Seth Larson, product manager at Viega LLC. The listing eliminates the need for contractors who have used PureFlow PEX throughout a house to have to join it to pipe of another material in the basement.

“Contractors who prefer PureFlow for its easy handling, fast connections and reliability will be happy to know that they can save time and money now that they can use the system throughout the entire house,” Larson said.

The listings cover two types of ceiling. PureFlow can be installed and left exposed in wood joist ceiling assemblies where the following conditions are met:

- Joists are of dimensional lumber, engineered wood, wood I-joist or open web wood joists (wood floor trusses)

- Joists are of depths from 6-16 inches (152-204 mm)

- Joists are of spacing from 12-24 inches (305-610 mm) on center

- Joists can be exposed after installation

- Metal pipe hangers spaced at maximum 24 inches (610 mm) on center are used

- Listed residential automatic sprinklers of maximum activation temperature rating of 165°F (68°C)

PureFlow can be installed exposed across finished ceiling assemblies where the following conditions are met:

- Ceiling is finished with one of the following approved membranes:

- Minimum 3/8 inch (9.5mm) thickness code-complying gypsum wallboard or;

- Suspended membrane ceiling with lay-in panels or tiles having a minimum weight of 0.35 lb/ft2 (1.76 kg/m2) when installed with metallic support grids or;

- ½ inch (13mm) code-complying plywood or solid sheathing

- Metal pipe hangers spaced at maximum 24 inches (610 mm) on center are used

- Listed residential automatic sprinklers of maximum activation temperature rating of 165°F (68°C)

PureFlow is the PEX fire sprinkler system of choice for builders and retrofitters for its ease of installation, corrosion-free qualities and dependability. It’s the only PEX fire sprinkler system with an easy alignment bracket that eliminates the need for measuring when hanging pendants.

For more information on Viega, click here.

Installers find design and installation benefits from PEX plumbing system for micro apartments project The Interurban Lofts in Shoreline, Wash., just outside of Seattle, are part of a new housing trend for millennials looking for a hybrid approach to home life. These “apodments,” as they’re called, feature a unique setup of eight studio units per Read more

Installers find design and installation benefits from PEX plumbing system for micro apartments project

The Interurban Lofts in Shoreline, Wash., just outside of Seattle, are part of a new housing trend for millennials looking for a hybrid approach to home life. These “apodments,” as they’re called, feature a unique setup of eight studio units per “pod” with a full bathroom in each unit and a shared kitchen. Each unit is partially furnished with a bed, microwave and mini-fridge.

The community atmosphere targets university students, recent graduates, young professionals and even seniors with the purpose of giving individuals more affordable housing and the opportunity to spend money on experiences, not spaces.

When planning the design for the six-story, 22,000-square-foot, 80-unit complex, the developers wanted a plumbing system that was efficient, durable and long-lasting, so they chose to go with PEX. Uponor’s design engineers and the Interurban Lofts project engineers worked in tandem to create an efficient system utilizing the flexible PEX piping along with ProPEX® expansion connections and multiport tees throughout.

When planning the design for the six-story, 22,000-square-foot, 80-unit complex, the developers wanted a plumbing system that was efficient, durable and long-lasting, so they chose to go with PEX. Uponor’s design engineers and the Interurban Lofts project engineers worked in tandem to create an efficient system utilizing the flexible PEX piping along with ProPEX® expansion connections and multiport tees throughout.

The project used more than 10,000 ft. of Uponor AquaPEX® tubing to plumb the entire structure. For a few of the installers, it was their first time working with Uponor PEX. Thankfully, onsite training from the manufacturer gave them a short-lived learning curve.

“Once you’ve tried making a fitting two times, you’ve got it. It just becomes common sense,” said Roman Hudson, foreman at Wolfe Plumbing. “The Milwaukee M18™ FORCELOGIC™ ProPEX expansion tool operates the same as the smaller tool — just pull the trigger and let it go.”

“Once you’ve tried making a fitting two times, you’ve got it. It just becomes common sense,” said Roman Hudson, foreman at Wolfe Plumbing. “The Milwaukee M18™ FORCELOGIC™ ProPEX expansion tool operates the same as the smaller tool — just pull the trigger and let it go.”

The team appreciated the faster, easier installation with the Uponor PEX system, which included a lighter-weight solution compared to copper and other metallic piping.

“PEX is more forgiving and it’s lighter than copper,” said Hudson. “We used to use CPVC, stainless and copper pipes, but ProPEX fittings, man, it’s quick and fast. Once you started figuring it out, PEX is faster.”

The benefits didn’t stop there. With the design expertise from a manufacturer that’s been in the PEX industry for more than four decades, the project also reaped additional advantages beyond the installation.

The benefits didn’t stop there. With the design expertise from a manufacturer that’s been in the PEX industry for more than four decades, the project also reaped additional advantages beyond the installation.

“The cool thing about Uponor Design Services is, because it’s their product, they’ll push the engineering to the max,” said Bert Shepardson, commercial plumbing project manager at

Wolfe Plumbing. “That’s what allows us to use smaller pipe sizes and have more favorable installs.”