https://vimeo.com/1056462403 A quick AHR recap: From sunny and 85 degrees to back to reality with 4 inches of snow and 15 degrees. While at the AHR Expo, we visit with Milwaukee Tool, Uponor and Bradford White. This Weekly Update is powered by our partners at Milwaukee Tool Read more

Plumbing

A quick AHR recap: From sunny and 85 degrees to back to reality with 4 inches of snow and 15 degrees. While at the AHR Expo, we visit with Milwaukee Tool, Uponor and Bradford White.

This Weekly Update is powered by our partners at Milwaukee Tool.

Atlanta—Celebrating a century of excellence, innovation, and ingenuity, Rheem®, a leader in the water heating and HVAC/R industry, with manufacturing facilities in 88 countries, will showcase the culmination of 100 years of engineering at the 2025 AHR Expo. Rheem’s family of 50 global brands — including Rheem Heating & Cooling, Rheem Water Heating, Eemax®, Friedrich®, HTPG®, IBC™, Nordyne®, and Raypak® — will present Read more

Atlanta—Celebrating a century of excellence, innovation, and ingenuity, Rheem®, a leader in the water heating and HVAC/R industry, with manufacturing facilities in 88 countries, will showcase the culmination of 100 years of engineering at the 2025 AHR Expo. Rheem’s family of 50 global brands — including Rheem Heating & Cooling, Rheem Water Heating, Eemax®, Friedrich®, HTPG®, IBC™, Nordyne®, and Raypak® — will present a range of dependable, cutting-edge, and environmentally friendly product options designed for commercial and residential use.

Stop by the RIDGID booth to try out their latest drain cleaning, diagnostic, and pressing solutions ELYRIA, OHIO – February 11, 2025 – RIDGID®, a part of Emerson’s professional tools portfolio, announced their participation in the WWETT Show, Feb. 18-20, in Indianapolis. This year’s in-booth experience will include demos of a new game-changing handheld cordless drain Read more

Stop by the RIDGID booth to try out their latest drain cleaning, diagnostic, and pressing solutions

ELYRIA, OHIO – February 11, 2025 – RIDGID®, a part of Emerson’s professional tools portfolio, announced their participation in the WWETT Show, Feb. 18-20, in Indianapolis. This year’s in-booth experience will include demos of a new game-changing handheld cordless drain cleaner, along with their latest underground technology and pressing solutions, an exclusive show meetup for industry pros with the chance to win one of three RIDGID tools, and the first chance to enter to win a spot at the 2025 RIDGID Experience.

“WWETT will be the first place to experience our new K-46 Cordless SinkSnake™, a handheld drain cleaner that features an industry-first integrated, multi-position kickstand that alleviates the challenges of working under cramped vanities and in tubs,” said Jeff Albertini, product management director, underground technologies and licensing, RIDGID. “It’s been designed to significantly improve ergonomics when drain cleaning in sinks, tubs, vanities, and showers and our team is excited to be able to share it with those attending WWETT.”

“WWETT will be the first place to experience our new K-46 Cordless SinkSnake™, a handheld drain cleaner that features an industry-first integrated, multi-position kickstand that alleviates the challenges of working under cramped vanities and in tubs,” said Jeff Albertini, product management director, underground technologies and licensing, RIDGID. “It’s been designed to significantly improve ergonomics when drain cleaning in sinks, tubs, vanities, and showers and our team is excited to be able to share it with those attending WWETT.”

Along with the K-46, RIDGID invites tradespeople to stop by the RIDGID booth (#2605) to experience their other drain cleaning, inspection, pipe rehabilitation, and pressing tools, including these latest solutions:

o NEW SeeSnake® microDRAIN APX CSx Via™ System – This kit features the SeeSnake microDRAIN APX, an inspection camera ideal for small pipes and tight turns with a flexible push cable and compact camera head to navigate small-diameter pipes, p-traps, and narrow bends where other systems struggle. Equipped with TruSense® technology and auto-image rotation, this inspection camera provides bright, clear images with real-time angle and orientation feedback. Paired with the CSx Via, the system offers a flexible, bring-your-own-screen solution to stream, capture, and share inspection images.

o FlexShaft® KM-1004 Milling Machine – This innovative hybrid milling machine provides heavy-duty milling and a wall-to-wall clean on 1 ¼ to 4-inch pipe up to 80 feet with unmatched efficiency. With cordless freedom, plug-in capability, first ever FlexShaft cable counter, and best-in-class durability, the FlexShaft KM-1004 Milling Machine allows users to adapt to tough jobsite conditions and makes in-field serviceability effortless.

o SeeSnake Mini Pro Inspection Camera with TruSense Technology – The first reel of its kind to provide digital self-leveling without mechanical rotation to maximize uptime, the small, yet rugged Mini Pro is designed to inspect up to 200 feet of 1 ½ to 8-inch pipe with its mid-flex push cable that can navigate hard 90-degree bends. Its innovative 25 mm digital self-leveling camera head always keeps the in-pipe image upright and, when paired with a TruSenseenabled monitor, the Mini Pro delivers the industry’s best in-pipe image with superior clarity, detail and fewer blown-out areas and sections of the pipe that are too dark to see.

o K-4310 FXP™ Drum Machine – The K-4310 features an industry-first cable counter that provides real-time, in-pipe cable distance in 3 to 10-inch lines for faster locating and diagnostics. Ideal for residential and commercial plumbing and drain cleaning projects, its powerful brushless DC motor spins at 230 RPM allowing you to tackle tough jobs with less required maintenance. The battery-powered K-4310 is also the newest addition to the FXP Technology Platform, delivering cordless freedom and powerful performance.

Other RIDGID drain cleaning, diagnostic, and press tools will also be available for demo including sectional machines, drum machines, jetters, SeeSnake® camera systems and locators.

Along with product demos, RIDGID is hosting a booth meetup on Feb. 18 at 2 p.m. where industry pros will have the chance to win a K-46 SinkSnake™, K9-204+ FlexShaft® Drain Cleaning Machine or microDRAIN APX and Via Kit. Additionally, the first day of the show will kick off the RIDGID Experience 2025 and the RIDGID WWETT booth will be the first opportunity for attendees to enter for their chance to win a spot on the eighth annual, all-expenses-paid trip to RIDGID headquarters. Throughout the show, attendees can also scan their badge to enter to win one of three K9-102+ FlexShaft Drain Cleaning Machines.

Thu, Feb 27, 2025 12:00 PM – 1:00 PM CST Register here: https://register.gotowebinar.com/register/6255693841565296736?source=evite1 Coffee with Caleffi™ Complimentary Technical Training Webinar Plumbing Codes and Certificates: Safety Essentials Technical Content Level: Fundamentals Join us for the first Coffee with Caleffi of the year, featuring Chris DeMarco, Regional Field Manager for IAPMO in the Mid-Atlantic region. In this Read more

| Thu, Feb 27, 2025 12:00 PM – 1:00 PM CST |

Register here: https://register.gotowebinar.com/register/6255693841565296736?source=evite1

Coffee with Caleffi™ Complimentary Technical Training Webinar

Located in suburban Detroit, Blue-Ray Mechanical, Inc. has evolved from a residential heating, cooling, and boiler company to offering dozens of services to both commercial and residential clients. Nearly 75 years old, the third-generation, family-owned and operated company serves half a dozen counties in the Detroit metro area. Partners Matt Landelius and Wes Evans and Read more

Located in suburban Detroit, Blue-Ray Mechanical, Inc. has evolved from a residential heating, cooling, and boiler company to offering dozens of services to both commercial and residential clients. Nearly 75 years old, the third-generation, family-owned and operated company serves half a dozen counties in the Detroit metro area.

Partners Matt Landelius and Wes Evans and their growing team of 16 staff members pride themselves on keeping up with the latest industry innovations and sharing them with customers. “We were one of the first companies to convert from coal to natural gas, seeing the environmental and sustainability benefits. The HVAC industry is constantly seeing innovative technologies, and it’s our duty to stay up to date with these trends,” said Landelius.

The BitRip app and BR Code labels were first conceived in military operations. The app was built for simplicity of operation, with the ability to add checklist forms for frequently inspected items like HVAC equipment, ladders, and fire extinguishers. The labels are built for durability, with indoor and outdoor versions available.

Landelius and Evans have roughly 21 years of experience apiece with Blue-Ray, and throughout that work experience they’ve sought a better way of tracking things like HVAC equipment, maintenance logs, personal protective equipment, etc. For example, Landelius explained that tracking just the HVAC equipment and its maintenance for one of their customers (with 36 retail stores) involved a very hefty and unwieldy black binder. “I was using this binder and typing all this stuff up as I was getting the information and then I have this big black binder in my work van with me that I have to keep flipping through,” he said.

So, it was a welcome discovery when Landelius first learned about BitRip® and BR Code™ labels. The app and labels offer a unique new way of connecting physical objects with a vast amount of customizable data and tracking every scanned location.

Dirty Rapidly Changing Environments

BitRip co-founder Nick Dimitruk initially conceived this solution in field combat operations more than a decade ago, while serving in the Middle East as a U.S. Marine. “We were in dirty, rapidly changing, dangerous places and using expensive, mission-critical gear. We realized that people in other industries had the same headaches, stress, and urgency to get the mission done quickly and effectively, so we invented this technology,” Dimitruk said.

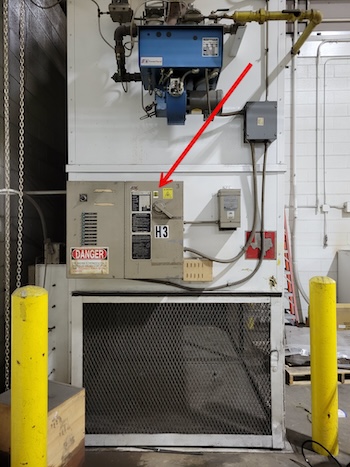

When Blue-Ray Mechanical Partner Matt Landelius first saw BitRip® and BR Code™ labels he quickly envisioned time resulting from their ability to connect physical objects with a vast amount of customizable data and tracking every scanned location.

Many of the same conditions are present in the rooftop HVAC spaces and mechanical rooms where Blue-Ray field technicians spend their time. Landelius saw BR Code labels and BitRip at a local supply house and immediately envisioned BitRip helping to eliminate the need for that big black binder.

“I tried it with a few (rooftop) units just to see how it would work and then I created a file for that store and then added all the units to it and I was able to send it to Wes and invite him into the project and that way he had it in his phone before he went there,” he recalled of that first trial. “We just rolled it out really quickly and it was really easy to use,” he said.

Now Blue-Ray staff uses the solution daily, replacing a lot of pen and paper and sticky notes and the need for staff to physically look at folders to access information. “We were really paper based, so BitRip makes it a lot easier,” Evans said.

Blue-Ray puts BR Code labels on rooftop units (RTUs), boilers, hot water systems, and other equipment, takes a photo of the manufacturer information tags, model and serial numbers, and specifics like refrigerant levels. Having all this information available so quickly and easily on a phone or mobile device “really helps out if someone calls and needs it.”

Creating Connectivity

“It makes it very easy to communicate with other techs or customers. It’s right there on our phones,” Landelius said. “It makes a really good tool as far as being in the field for right on the spot, connectivity, and being able to figure out what we need and when we need it,” Evans added.

For RTUs, Landelius generally scans the BR Code, then enters the name of the unit, the customer who owns it, what rooftop number it is, he then takes a photo of the tag and adds a note for its filter and belt sizes and whether any service has been done. He creates another note that serves as a service log.

All of this information is securely stored in the cloud within the BitRip app, and the Blue-Ray team controls who has access to the information. They appreciate that the labels can be locked so that people don’t get in there and “play around.”

Being able to remotely access key information like this before visiting a jobsite has been a true game changer, Landelius said. Evans said that another area where the app and labels are providing value is increasing billing transparency. Having a service log associated with the label that is right on the HVAC equipment that shows what repairs were performed, and when, is extremely valuable, he said.

“Everything seems to be going to connectivity through your phones…so, having BitRip to be able to share with other techs in the field I think will just shorten time on the phone, time waiting, time going to supply houses. You’re going to be able to share this exactly with another tech or your homeowner or business owner or property manager, and I think it’ll really shorten up the time that we’re wasting either being on the phone or driving to get parts after the fact of getting to a job when you could have come with parts,” Evans said.

The BitRip and BR Code label solution is “easily affordable,” according to Evans. He said that not having to carry a laptop or an iPad on a jobsite to input data is a bonus. Landelius added that the minimal cost of BR Code labels is easily built into any project’s billing. They have been using the heavy-duty BR Code labels and have been impressed with their ability to stay where they’re placed.

No More Black Binders

Landelius said that the unpopular task of updating the big black binder for each client is becoming outdated thanks to this solution. “We change units regularly at all these different buildings. I have to update that thing once a month and that requires me to be at home with the computer and sit there and I’m not the greatest typer so I’m just pecking away at the keyboard, but now, I don’t have to do it.”

Blue-Ray Mechanical puts BR Code labels on rooftop units (RTUs), boilers, hot water systems, and other equipment, and then they typically add a photo of the manufacturer information tags, model and serial numbers, and specifics like refrigerant levels.

He added that communicating with dozens of text messages and phone calls/voicemails each day multiplied by four technicians going to different jobs throughout the area eats up a massive amount of time. That time is now being spent more productively thanks to BitRip and BR Code labels.

BitRip has seen a huge adoption in the safety inspection tracking sector with checklist forms for different items like ladders, fire extinguishers and personal protective equipment. And Blue-Ray is considering using BitRip for those types of applications as well.

“BitRip makes it easy to be able to share and transfer information. I think it’s just going to make it easier the more jobs we go to, the more stickers we put up. I think in a couple of years, we might have the majority of our main accounts and residential, commercial, light industrial tagged up,” Evans said. As Blue-Ray continues to evolve Landelius and Evans are excited to see how this digital technology can continue to improve their bottom line.