With more and more homeowners looking to smart technologies to automate their homes, people can now automate almost anything — lights, garage doors, windows, blinds, appliances, clocks, speakers, door bells, surveillance cameras, home security systems, climate control systems, cleaning systems, sprinkler systems, lawnmowers — even food preparation. So, what about their plumbing systems? If you Read more

Uponor

With more and more homeowners looking to smart technologies to automate their homes, people can now automate almost anything — lights, garage doors, windows, blinds, appliances, clocks, speakers, door bells, surveillance cameras, home security systems, climate control systems, cleaning systems, sprinkler systems, lawnmowers — even food preparation.

Phyn Plus installed with Pro Squad installer

So, what about their plumbing systems? If you think about it, homeowners would love to be connected to their plumbing systems. What if a pipe bursts when they’re away? Or, there’s a tiny leak that’s been quietly wasting water (and money) for months (think: toilet flappers, dripping faucets or pinhole leaks in corroded metal plumbing systems). For those that only get their water bill on a quarterly basis, that little leak could add up to quite a big cost over time (not to mention a tragic waste of water, our precious natural resource).

And, it doesn’t necessarily have to be a leak. There are those forgetful homeowners (or their children) who leave a faucet running and leave the house with the water going continuously. I’ve even heard of pets (typically cats) that accidentally turn on faucets and leave them running for hours until the homeowner returns to find little Fluffy has just wasted hundreds of dollars down the drain. Certain smart water detection systems can even alert homeowners of abnormal water events such as these.

Water leaks and water misuse are real, and every homeowner has experienced a water incident at one time or another. If you’re still not convinced, here are some interesting stats that might make you think differently.

- According to the Insurance Information Institute, water damage accounts for almost half of all property damage claims.

- About one in 50 insured homes has a property damage claim caused by water damage or freezing each year, and water damage ranks as the second most common home insurance claim.

- Of homeowners who have experienced a water leak claim in the past two years, 57% spent more than $5,000 on clean-up costs, and 15% spent $20,000 or more.

- 41% of homeowners say a device that alerts them to water leaks is highly

If you haven’t thought about it, now’s the time. Intelligent water is the next frontier in the connected home, and plumbers can benefit greatly from this new technology. Adding a smart water technology offering to your plumbing business is a great way to gain new business and offer a valuable new benefit to existing customers.

How do you get started? First, you need to do your research. Certain manufacturers now offer smart water systems that are designed specifically with the professional plumber in mind. The Phyn Plus smart water assistant + shutoff, for example, is a connected plumbing device that is installed by a plumber in the Pro Squad nationwide network.

How do you get started? First, you need to do your research. Certain manufacturers now offer smart water systems that are designed specifically with the professional plumber in mind. The Phyn Plus smart water assistant + shutoff, for example, is a connected plumbing device that is installed by a plumber in the Pro Squad nationwide network.

It’s helpful if you’re familiar with the internet and have some tech savvy in your background. But, for products that are installed through a professional, exclusive network, you can get the training you need right from the manufacturer. All that’s required from you is a willingness to learn.

Think about it. Homeowners are craving new ways to get connected to the things in their homes, and they are willing to pay for it. They will pay you for it! Plus, when there is a leak detected in their home, guess who they’ll call?

These smart water technology systems are a wonderful revenue generator for anyone in the plumbing industry — from the established contractor to someone just breaking into the industry. They can apply to any type of application from new construction to remodels to re-pipes. Essentially anywhere there’s residential plumbing, these systems will work.

And think about how great it would be to have your customers calling you straight from their connected device’s app whenever they need service due to a leak. It takes the guesswork out of the equation for homeowners regarding the best professional to call for the job, and it ensures a faithful client base for you. Win-win.

And think about how great it would be to have your customers calling you straight from their connected device’s app whenever they need service due to a leak. It takes the guesswork out of the equation for homeowners regarding the best professional to call for the job, and it ensures a faithful client base for you. Win-win.

So, if you’re ready to up the ante in your business to offer a smart water leak detection system, think about all the positives it can offer and how easy it can be to get trained and up and running on a technology that is going to be in demand in the very near future.

You could be one of the first in your area to offer it, opening doors to customers you might never have the opportunity to encounter otherwise.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

For a more cost-effective ball valve option for ASTM F1960 PEX-based hydronic heating and cooling applications, look to Uponor’s ProPEX® brass ball valves. These commercial-grade, full-port ball valves are available in ½” to 2″ sizes and are appropriate for non-potable PEX piping systems containing up to 50 percent propylene glycol. The valves feature blow-out-proof stems Read more

For a more cost-effective ball valve option for ASTM F1960 PEX-based hydronic heating and cooling applications, look to Uponor’s ProPEX® brass ball valves. These commercial-grade, full-port ball valves are available in ½” to 2″ sizes and are appropriate for non-potable PEX piping systems containing up to 50 percent propylene glycol. The valves feature blow-out-proof stems and are available with stem extension kits to accommodate up to 2″ of insulation. They are code-compliant and listed to ANSI/NSF 14 and cNSFus-rfh and tested to ASTM F877, ASTM F1960, CSA B137.5 and NSF 359.

For a more cost-effective ball valve option for ASTM F1960 PEX-based hydronic heating and cooling applications, look to Uponor’s ProPEX® brass ball valves. These commercial-grade, full-port ball valves are available in ½” to 2″ sizes and are appropriate for non-potable PEX piping systems containing up to 50 percent propylene glycol. The valves feature blow-out-proof stems and are available with stem extension kits to accommodate up to 2″ of insulation. They are code-compliant and listed to ANSI/NSF 14 and cNSFus-rfh and tested to ASTM F877, ASTM F1960, CSA B137.5 and NSF 359.

Visit uponorengineering.com to download CAD and BIM design files for fast and easy specification and design.

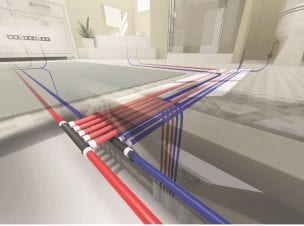

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system. However, you may not know there’s a new (and smarter) way to design and install a residential plumbing Read more

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system.

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system.

However, you may not know there’s a new (and smarter) way to design and install a residential plumbing system that installs faster, uses less materials, requires fewer connections, minimizes your liability and operates more efficiently.

It’s called Logic plumbing.

A Logic plumbing design can only be used with PEX piping, but since PEX is now used in more new-home construction than copper and CPVC combined, you’re most likely already using it. (And if you’re not, you need to check it out. PEX is highly durable, flexible and more cost-effective compared to copper and CPVC.)

The Logic approach leverages the flexibility of PEX pipe to minimize connections and reduce potential leak points while also incorporating multiport tees located near fixture groupings to both limit the amount of pipe and connections needed while also improving installation efficiencies and system performance.

What’s a multiport tee?

I’m sure right now you’re wondering, “What’s a multiport tee?” It’s essentially a bunch of tees all molded together to create one long tee with multiple outlets. This innovative product minimizes connections and is the heart and soul of a Logic design.

For example, six regular tees will have 18 connections, but a flow-through multiport tee with six outlets will only have eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Think about how much faster you could install a system when you’re making half the number of connections.

For example, six regular tees will have 18 connections, but a flow-through multiport tee with six outlets will only have eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Think about how much faster you could install a system when you’re making half the number of connections.

And get this — while multiport tees may resemble a manifold, they have the benefit of being hidden behind walls without the need for an access panel. Yes, you heard that right. No need for an access panel, minimizing costs and labor to help keep your projects on schedule and on budget.

Multiport tees are made of engineered polymer (EP), a thermoplastic material that has been used in plumbing applications for more than 20 years. EP has superior mechanical, chemical and thermal properties that provide dimensional stability in demanding applications, including areas of high stress, heat and moisture.

And, like PEX, the EP material in multiport tees resists corrosion, pitting and scaling, so it creates a highly durable system that’s engineered to last. Best of all, multiport tees (as well as all EP fittings) are approved for direct burial in the soil or concrete slab, so they are ideal for in-slab plumbing applications.

The Logic layout

So what exactly is a Logic plumbing layout? It’s quite simple: a main line connects to a multiport tee with distribution lines going out from the tee. These individual lines extending from the single multiport tee provide water to all fixtures in a single or adjacent grouping.

This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

For example, a 2,300-square-foot, two-story home using a Logic design requires only 637 feet of pipe while a home-run system uses 1,515 feet of pipe. That’s more than twice the amount of piping necessary.

In addition to the added costs required to install all that extra pipe, the system performance is also greatly reduced due to added pressure loss and longer wait times for hot water. Plus, all the extra pipe can lead to issues isolating hot and cold water lines. This increases heat transfer and energy inefficiencies within the plumbing system.

And, while it’s true a Logic installation uses slightly more connections than a home-run layout (59 vs. 48 in the 2,300-square-foot, two-story home example above), the amount of pipe savings is significantly more beneficial with the labor and material savings you get with less pipe to install (not to mention the efficiency of the system).

A Logic layout also installs much faster compared to a trunk-and-branch system due to the vast reduction in connections. With the two-story home example above, a Logic layout uses a mere 16 fittings and 59 connections compared to a whopping 96 fittings and 165 connections for trunk and branch. That’s six times the number of fittings and nearly three times the amount of connections!

All those added connections greatly increase your liability with more potential for leaks, plus it also limits the performance of the system with increased pressure loss.

So there you have it! Just a few “logical” reasons why you should consider a smarter approach to plumbing a home that will improve your installation times, limit your liability and offer an all-around better-performing system for the end user.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

John Reutter has been named the new vice president of Finance for Uponor North America. He will lead all of the company’s finance-related teams, including Accounting, Finance, Risk Management and Legal. Bill Gray, president of Uponor North America says, “John’s experience working in the water and energy industries, assisting with integrations, incorporating financial metrics into Read more

John Reutter has been named the new vice president of Finance for Uponor North America. He will lead all of the company’s finance-related teams, including Accounting, Finance, Risk Management and Legal.

John Reutter has been named the new vice president of Finance for Uponor North America. He will lead all of the company’s finance-related teams, including Accounting, Finance, Risk Management and Legal.

Bill Gray, president of Uponor North America says, “John’s experience working in the water and energy industries, assisting with integrations, incorporating financial metrics into strategic goals, and guiding the financial aspects of multimillion-dollar projects were key factors in his selection. We’re excited to have John as part of our senior leadership team. I’m confident he will play an important role in the continued growth of our organization throughout North America.”

Sometimes its fun to step back and see the whole process from start to finish. Here’s a time lapse video of the prep and install for the radiant in-floor heating at the #duluthbuild project in Northern Minnesota. I’ve been trying to document each step along the way for this project we are building for my Read more

Sometimes its fun to step back and see the whole process from start to finish. Here’s a time lapse video of the prep and install for the radiant in-floor heating at the #duluthbuild project in Northern Minnesota.

I’ve been trying to document each step along the way for this project we are building for my little sister and brother-in-law and I’m starting with the over 7K sq ft of radiant. If you’d like to follow along you can search the hashtag #duluthbuild on either Facebook or Instagram, doing so will show you all the posts from the project.

If social media isn’t your thing or you’d just rather stay put here on The Hub check out these recent videos:

What is permanent? What will be there in 100 years?

Uponor Ecoflex pre-insulated job site install