In the last several decades, increasing regulations on lead content in drinking water systems have directly impacted the evolution of plumbing materials. For Viega, the transition from leaded bronze to ZL (zero-lead) bronze represented a significant milestone in ensuring compliance and advancing industry standards. This is further exhibited by the Viega MegaPress® Transition Coupling, which Read more

Viega

In the last several decades, increasing regulations on lead content in drinking water systems have directly impacted the evolution of plumbing materials. For Viega, the transition from leaded bronze to ZL (zero-lead) bronze represented a significant milestone in ensuring compliance and advancing industry standards. This is further exhibited by the Viega MegaPress® Transition Coupling, which uses press technology to make transitioning between different systems easier than ever before.

The Shift to Lead-Free Alloys

Regulations on lead content have appeared with respect to gasoline, paint and plumbing systems.

- 1974: The Safe Drinking Water Act (SDWA) was originally created in 1974 and been amended in 1986 and 1996. Allowed the EPA to regulate public water systems and impose limits on contaminants.

- 2008: California and Vermont reduced allowable lead content to 0.25% weighted average across wetted surfaces.

- 2011: The federal Reduction of Lead in Drinking Water Act (RLDWA) mandated a nationwide 8% lead limit.

- 2014: Full enforcement of RLDWA required manufacturers to adopt zero-lead materials for all new potable water systems, further reducing the lead limit for pipes, fittings, and fixtures to less than 0.25%.

These regulatory changes led to the development and adoption of alternative alloys that meet lead content requirements while maintaining performance.

Challenges in Transitioning to Zero-Lead Bronze

The shift from leaded to lead-free components presented significant engineering and manufacturing challenges:

- Material Properties: Traditional leaded bronze offered superior machinability due to lead’s lubricating properties. Lead-free alternatives, such as silicon and phosphorus-bronze alloys, required modifications of machining processes to mitigate tool wear and burr formation.

- Casting and Forming: Lead also contributes to metal fluidity, reducing shrinkage defects. Transitioning to zero-lead alloys necessitated mold redesigns and optimized casting techniques.

- Soldering and Brazing: The wetting behavior of lead-free materials differs from leaded solder, requiring adjustments to flux compositions and brazing temperatures. Installation techniques had to adapt as well due to differential heating between this new bronze and copper tubing.

- Corrosion Resistance: Some zero-lead alloys are more prone to dezincification and stress corrosion cracking, increasing the need for dezincification-resistant (DZR) alloys staying below 15% zinc or adding inhibitors.

- Compliance and Cost: Meeting NSF/ANSI/CAN 61 and 372 standards involved significant investment in new tooling, certification, and material procurement.

The Importance of Dezincification-Resistant (DZR) Bronze

Dezincification occurs when zinc is leached from brass, leaving a porous, weakened structure. Viega’s ZL bronze incorporates DZR properties to ensure:

- Enhanced corrosion resistance in aggressive water environments.

- Longer-lasting performance in high-temperature applications.

- Regulatory compliance without compromising material strength or durability.

Leading the Industry Forward

As part of our commitment to innovation and regulatory compliance, our zero-lead fittings exemplify how advanced material science can support safe drinking water initiatives. Notably, the MegaPress Zero-Lead Bronze Transition Coupling is the first and only press coupling of its kind, setting the standard as a durable, reliable and compliant solution for the plumbing industry.

https://vimeo.com/1074098129 On this Weekly Update—April 11, 2025, we talk tariffs, a visit with American Plumber Stories while some plumbers prepare for a turkey hunt and we visit with our friends at InSinkErator Read more

On this Weekly Update—April 11, 2025, we talk tariffs, a visit with American Plumber Stories while some plumbers prepare for a turkey hunt and we visit with our friends at InSinkErator.

https://vimeo.com/1071965170 On this week’s Mechanical Hub weekly update, we talk about the unpredictability of the weather, Utah’s Fluoride ban in drinking water, April Fool’s jokes, a visit with our friends from Viega and the Appetite for Construction podcast, which features Jorge Arias, vocational plumbing instructor at the Correctional Training Facility (CTF) Soledad State Prison in Read more

On this week’s Mechanical Hub weekly update, we talk about the unpredictability of the weather, Utah’s Fluoride ban in drinking water, April Fool’s jokes, a visit with our friends from Viega and the Appetite for Construction podcast, which features Jorge Arias, vocational plumbing instructor at the Correctional Training Facility (CTF) Soledad State Prison in California.

The publication of ASTM B1029 marks another milestone for the growing press industry Viega is proud to announce the publication of the ASTM B1029: Standard Practice for Press-Connect Joints with Seamless Copper and Copper Alloy Tube and Press Fittings. ASTM is a global organization that develops and provides standards for various industries and applications. Viega Read more

The publication of ASTM B1029 marks another milestone for the growing press industry

Viega is proud to announce the publication of the ASTM B1029: Standard Practice for Press-Connect Joints with Seamless Copper and Copper Alloy Tube and Press Fittings. ASTM is a global organization that develops and provides standards for various industries and applications. Viega took part in a rigorous consensus process to document best practices for creating press-connect joints. The new ASTM B1029 standard aims to enhance the reliability, efficiency, and adoption of press-connect technology in its approved applications by providing a standardized practice to be used industry-wide.

As a leader in the industry, Viega’s history, expertise, and innovative approach was instrumental in shaping this standard. Their commitment to innovation and quality is reflected in ASTM B1029, which aligns with the company’s mission to provide solutions that meet the highest industry standards. By collaborating with ASTM, Viega aims to support the widespread adoption of press-connect technology, offering engineers and installers a reliable, predictable, and efficient alternative to traditional joining methods.

Call to Action for Engineers and Specifiers

Viega encourages engineers, specifiers, and installers to incorporate ASTM B1029 language and practices into their projects to take advantage of the benefits offered by press-connect technology. The standard provides a clear framework for achieving optimal joint integrity and system performance.

Benefits of Press-Connect Technology:

- Fast: Press-connect fittings significantly reduce installation time compared to traditional methods.

- Safe: Eliminates the need for open flames or chemicals, reducing the risk of fire and exposure to harmful substances.

- Versatility: Suitable for a wide range of applications, from residential plumbing to complex industrial systems.

- Consistent: Simple connections create less variability between installers and more reliable systems.

The Plastics Pipe Institute, Inc. (PPI) announced today that its Building & Construction Division (BCD) has elected Bill Melvin of Legend Valve (Auburn Hills, MI) as Division Chair and Jim Paschal of Aquatherm (Lindon, UT) as Vice Chair. Melvin, who will also represent the division on the PPI Board of Directors for the next two Read more

The Plastics Pipe Institute, Inc. (PPI) announced today that its Building & Construction Division (BCD) has elected Bill Melvin of Legend Valve (Auburn Hills, MI) as Division Chair and Jim Paschal of Aquatherm (Lindon, UT) as Vice Chair. Melvin, who will also represent the division on the PPI Board of Directors for the next two years, takes over from Joseph Poniatowski of Asahi/America. The changes took effect June 1, 2024. PPI’s BCD focuses on pressure piping materials for plumbing and mechanical applications.

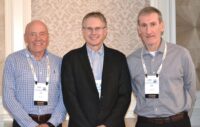

Jim Paschal (left) of Aquatherm, new Vice Chair and Bill Melvin (right) of Legend Valve new Chair of PPI’s Building & Construction Division with Lance McNevin, the engineering director for the division.

Bill Melvin has served on the Management Committee in several roles, including the Communications Committee Chair and Vice Chair. Jim Paschal also serves as Chair of PPI’s Polypropylene Pressure Pipe Steering Committee and formerly served as R&D Projects Chair. That position will now be filled by Rick Stock of Uponor. Brian Conner of Charlotte Pipe and Foundry joins the committee as Codes & Governments Affairs Committee Liaison.

Rick Stock, Uponor

Adam Grier of iNOEX serves as the Communications Committee Chair, and also as Chair of the PPI Umbrella Marketing Committee. Jason McKinnon of Viega LLC serves as the PPI Education Committee Chair and also as the BCD Education Chair, a position he has held for more than eight years. Forest Hampton III of Lubrizol continues as Advisory Council Liaison & Strategic Planning Chair.

According to Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division, “PPI’s management committee members provide significant guidance to staff on topics from research, codes and standards to education and advocacy. These new leadership positions solidify their continued commitments to PPI and the piping industry. We are grateful for the volunteer service of these dedicated members.”

Brian Conner, Charlotte Pipe and Foundry

PPI is the major North American trade association representing the plastic pipe industry. The Building & Construction Division represents plastic pressure piping materials such as CPVC, HDPE, PEX, PE-RT, PP-R, and PP-RCT.

More information can be found at https://plasticpipe.org/buildingconstruction