Since their introduction in North America in 1999, Viega press systems have earned a loyal following among plumbers and contractors who value their performance, efficiency and reliability. In recent years, this community has grown into a large following across Viega LLC’s social media accounts. In response, Viega LLC is recognizing some of its most enthusiastic Read more

Viega

Since their introduction in North America in 1999, Viega press systems have earned a loyal following among plumbers and contractors who value their performance, efficiency and reliability.

In recent years, this community has grown into a large following across Viega LLC’s social media accounts. In response, Viega LLC is recognizing some of its most enthusiastic and influential supporters through a new Press Masters Brand Ambassador program. The Press Masters are a group of highly skilled plumbing, HVAC, and general contractors who have built followings through their creative, and often entertaining, educational social media content.

In recent years, this community has grown into a large following across Viega LLC’s social media accounts. In response, Viega LLC is recognizing some of its most enthusiastic and influential supporters through a new Press Masters Brand Ambassador program. The Press Masters are a group of highly skilled plumbing, HVAC, and general contractors who have built followings through their creative, and often entertaining, educational social media content.

As Press Masters, they will use their social channels to educate people on the benefits of pressing with Viega fittings and share their trade expertise.

“The Press Master brand ambassador program is centered around building relationships with people who have shown great pride in their work using Viega fittings and who are passionate about being involved in the trade community,” said Rebecca Stamey, PR and Social Media Manager for Viega. “There is so much value in having the opportunity to partner with people who choose to use our products every day. We want to recoginize their endorsement for the brand and celebrate their accomplishments, all while also helping other realize the benefits of pressing.”

The current Press Masters are:

- Travis Abaire, @t.a.p.plumbingandheating, of Tap Plumbing & Heating in Bristol, Conn.

- Matt Fleming, @allstarplumbinginc, of All Star Plumbing & Heating in Manasquan, N.J.

- Terence Chan, @the__impetus, of Impetus Plumbing & Heating in Vancouver, B.C.

- Jonathan Cheever, @teamcheever, of Team Cheever Design Build in Park City, Utah

- Matt Benevides, @boston_plumbing_monstahs_, of Benevides Plumbing & Mechanical in New Bedford, Mass.

- Colton Henkowski, @viking_pipefitter, Technical Trainer for Viega in Broomfield, Colo.

To learn more about each Press Master and for those interested in applying to join the program visit viega.us/pressmasters.

Viega will sponsor pit crew in select races and have presence on the No. 47 Camaro ZL1 throughout the NASCAR Cup Series season. JTG Daugherty Racing has united with Viega, which is a a worldwide leader in pipe fitting installation technology for industrial, commercial, and residential projects. Viega is sponsoring the newly formed JTG Daugherty Read more

Viega will sponsor pit crew in select races and have presence on the

No. 47 Camaro ZL1 throughout the NASCAR Cup Series season.

JTG Daugherty Racing has united with Viega, which is a a worldwide leader in pipe fitting installation technology for industrial, commercial, and residential projects. Viega is sponsoring the newly formed JTG Daugherty Racing pit crew, and will have placement on Ricky Stenhouse Jr.‘s No. 47 Camaro ZL1 C-Post throughout the entire NASCAR Cup Series season.

“Viega supports professionals that make things happen, and we’re aligned to promote the high quality of their products,” Stenhouse Jr. said. “Pit crews are professionals with a special skill set, and they must have the right tools to do their job to work fast, efficiently and effectively just like the trades people working with Viega products. We have a fitting pit crew that Viega has partnered with this season. We’re looking forward to being successful on and off the track together, and communicating that Viega’s press technology is a safer secure alternative for connecting pipe.”

Viega’s saying is “Fast, Safe and Secure.” That key messaging will be showcased on the yellow and black Viega pit crew uniforms specially featured during 11 NASCAR Cup Series races this year when they service Stenhouse’s race car.

“Races are won and lost in the pits – it’s all about maximum efficiency and knowing the wheels are safely secured,” said Jared Mackrory, Viega Marketing

Director. “It’s the same challenge the professionals in our industry face as they install pipe fittings and hustle to get critical lines back up and running. We love that shared connection and are proud to support the professionals on the JTG Daugherty Racing pit crew.”

Viega’s pit crew uniform branding will include Las Vegas Motor Speedway (both races 3/6 & 10/16), Circuit of The Americas (3/27), Talladega Superspeedway (4/24), Dover Motor Speedway (5/1), Kansas Speedway (5/15), World Wide Technology Raceway (6/5), New Hampshire Motor Speedway (7/17), Pocono Raceway (7/24), Michigan Speedway (8/7), Watkins Glen International (8/21).

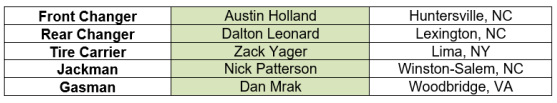

Viega is also pleased to announce the pit crew lineup for those races as follows:

For More information visit http://www.viega.us/ or contact the company at communications@viega.us.

There’s never a good time for a water-main break. But when it happens in the aftermath of a major hurricane, well, that can certainly throw a wrench into things. In September, just after Hurricane Ida hit the United States, staff at Massachusetts Maritime Academy in Buzzards Bay were scrambling. They were preparing for students to Read more

There’s never a good time for a water-main break. But when it happens in the aftermath of a major hurricane, well, that can certainly throw a wrench into things.

In September, just after Hurricane Ida hit the United States, staff at Massachusetts Maritime Academy in Buzzards Bay were scrambling. They were preparing for students to arrive on campus the next day, but a water pipe burst in one of the dormitories.

There was no time to waste. The break had to be fixed immediately or the school would need to delay students’ arrival on campus. In the aftermath of Ida, a massive Nor’easter was unleashed in the New England area, adding to the craziness of the day.

Facility staff at MMA keep Viega fittings and tooling onsite for repairs to what is an aging system, but – as Murphy’s Law would have it – they only had tooling for up to 2” and they needed ProPress rings for 2½” tubing. That’s when Andrew Hiller of CGW Associates got a phone call.

“I raced to my facility to see what tooling I had, but the storm was just massive. The rain was incredible,” Hiller said. “I got rerouted because our main route was underwater – about five feet in some areas.”

Hiller discovered he didn’t have the correct-size rings either, so he called Viega District Sales Manager Dan Paine and told him what he needed. Paine could get the rings from a central storage facility, and the two men coordinated to meet soon after so that Hiller could drive the tools over to MMA.

“I drove through the deepest puddle I’ve ever been through,” Hiller said. “It wasn’t a very big section, but it was very deep!”

Once Hiller got the jaws to MMA, they replaced the entire section of pipe, about 25 feet in length. He said it was aging and a bad design, plus it was a difficult area in which to make the repair. But thanks to Viega fittings and the quick actions of Hiller and Paine, the repair was complete and MMA was back online, ready for students.

“When our customers need something, Viega is there to help as quickly as we can,” Paine said. “People trust Viega because they know they’re not just getting a great product, but also the service and support that go along with it. I was glad we could lend a hand to help the school get back up and running quickly, with as little interruption as possible.”

RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, announces that Milwaukee® Tool, in partnership with RLS, has introduced RLS-compatible jaws for use with its popular M18™ FORCE LOGIC™ Press Tools. Available in sizes from 1/4″ – 1-3/8″, these new RLS ACR Press Jaws will allow Read more

RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, announces that Milwaukee® Tool, in partnership with RLS, has introduced RLS-compatible jaws for use with its popular M18™ FORCE LOGIC™ Press Tools.

Available in sizes from 1/4″ – 1-3/8″, these new RLS ACR Press Jaws will allow M18 tool users to take advantage of the time-saving and safety benefits of flame-free RLS press connections for HVAC/R, without needing to invest in a new press tool. These are the industry’s first jaws approved to press RLS fittings using 32 kN (kilonewton) tools.

In addition, the new Milwaukee jaws are also compatible with a wide range of other 32 kN tools on the market, including those from manufacturers such as RIDGID, Klauke, Viega, Dewalt, NovoPress and Rothenberger. Contractors who already own any of these tools will only need to purchase the Milwaukee jaws to begin installing RLS fittings.

Milwaukee’s RLS-compatible jaws will be sold exclusively through Milwaukee distributors. Contact Milwaukee or visit milwaukeetool.com for details. For more information on RLS press fittings, and a complete RLS Tool & Jaw Compatibility Matrix, visit rapidlockingsystem.com.

About RLS Fittings

RLS press fittings connect in 10 seconds using a battery-powered tool and jaws, replacing the time-consuming process of manually brazing HVAC/R joints. The fittings result in faster, more consistent connections that reduce total installed costs, while also increasing jobsite safety by eliminating the use of an open flame. More than 10 million RLS fittings have been successfully installed since their introduction in 2015

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A Read more

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes

Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A scan of the code will send the user to the product instruction page on viega.us. It’s estimated that this will eliminate more than 6 million pieces of paper a year, paper which often wound up littering jobsites.

Having the instructions in digital format means any updates are immediately and automatically reflected, another benefit.

“Viega LLC is committed to reducing its environmental impact in ways big and small,” said Adam Botts, Portfolio Manager for piping systems. “This is an example of a simple measure that, in total, will save an enormous amount of paper without inconveniencing customers. This absolves them of having to recycle or dispose of the instruction sheets properly. We look forward to rolling out additional initiatives, both seen and unseen, that will have positive impacts on our company footprint.”

Earlier this year, Viega Holding GmbH & Co., parent company of Viega LLC, was named one of the 50 Sustainability & Climate Leaders by TBD Media Group.