ASCO’s lead-free brass solenoid valves have been helping mechanical contractors and plumbers comply with the EPA’s Safe Drinking Water Act’s low lead requirements ever since 2015. The ASCO product line is continuously evolving to provide solutions to help end users with clean water automation. As part of our innovation roadmap, ASCO will be providing new Read more

Viega

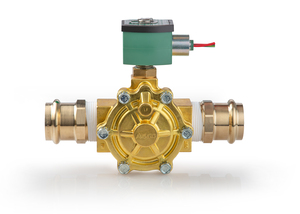

ASCO’s lead-free brass solenoid valves have been helping mechanical contractors and plumbers comply with the EPA’s Safe Drinking Water Act’s low lead requirements ever since 2015. The ASCO product line is continuously evolving to provide solutions to help end users with clean water automation. As part of our innovation roadmap, ASCO will be providing new laborsaving end connectors that will increase the speed of meeting EPA SDWA requirements.

These labor-saving features include the adoption of Viega ProPress and PureFlow fittings which allow mechanical contractors and plumbers to install ASCO lead-free valves with a RIDGID Press Tool in seconds. No hot work permit and no plumbing unions required. ASCO’s wide range of electrical connections also reduce delays in inspection time, with a ½” NPT conduit as a standard option.

Features and Benefits

Features and Benefits

- Helps contractors and plumbers meet EPA Safe Drinking Water Act low lead requirements in seconds.

- Viega ProPress and PureFlow fittings are factory installed to ASCO’s Lead-Free Brass Valves, and leak tested, reducing installation delays.

- ASCO’s Lead-Free Brass Valves come with a wide range of electrical connections, reducing delays during inspections.

For more information, please visit www.emerson.com/leadfree.

Bigger, better truck delivers mobile tradeshow experience Viega LLC is bringing its tradeshow experience to customers across the country with a new and bigger demo truck. The new Viega Roadshow truck displays a complete line of Viega products, including the ProPress, MegaPress and PureFlow fittings, PureFlow tubing, as well as valves, radiant heating systems and Read more

Bigger, better truck delivers mobile tradeshow experience

Viega LLC is bringing its tradeshow experience to customers across the country with a new and bigger demo truck.

The new Viega Roadshow truck displays a complete line of Viega products, including the ProPress, MegaPress and PureFlow fittings, PureFlow tubing, as well as valves, radiant heating systems and marine fittings. The 30-foot vehicle has two slideouts, a folding stage to safely accommodate more visitors and an island for hands-on demonstration of Viega tools and products.

“Viega put a lot of time and thought into designing this vehicle,” said Jim DeBroeck, the project manager. “As a result, it virtually duplicates the tradeshow experience for customers without them having to travel. Rather, we bring it to them.”

“Viega put a lot of time and thought into designing this vehicle,” said Jim DeBroeck, the project manager. “As a result, it virtually duplicates the tradeshow experience for customers without them having to travel. Rather, we bring it to them.”

The new black-and-yellow truck replaces a smaller vehicle that was pulled off the road last year when the pandemic began. The customized V8-powered Ford F-650 has been on the road since August. It will continue to travel throughout the continental United States, visiting distributors, tradeshows, construction sites and plumbing associations.

The wall displays have been designed to not only highlight the products, but also educate visitors about how to use the products and how Viega can benefit their businesses.

“The truck delivers the ‘a-ha’ moment for customers. When they see the range of Viega products, pull the trigger on a press tool and learn about the efficiencies Viega delivers, they will have what they need to incorporate Viega systems into their work and begin realizing the benefits,” DeBroeck said.

Viega LLC manager Daniel Rademacher has won the PMG Leadership Award from the International Code Council (ICC) for his work in training and educating plumbing professionals around the world. Rademacher, who is the Trades Education Network (VTEN) Program Manager for Viega, was given the award at the ICC’s annual meeting Sept. 18-28 in Pittsburgh, Pa Read more

Viega LLC manager Daniel Rademacher has won the PMG Leadership Award from the International Code Council (ICC) for his work in training and educating plumbing professionals around the world.

Rademacher, who is the Trades Education Network (VTEN) Program Manager for Viega, was given the award at the ICC’s annual meeting Sept. 18-28 in Pittsburgh, Pa. The award is given each year to an individual or organization for exceptional service to the plumbing, mechanical, fuel gas and swimming pool/spa (PMG) industry.

“Dan’s passion for providing relevant and engaging learning opportunities so that plumbing professionals can achieve their career goals, no matter where they are located, is unmatched,” the ICC stated.

“I’m humbled to receive this award from the ICC, an institution which has done so much to advance plumbing and promote the well-being of people around the world,” Rademacher said. “And I’m proud to be able to introduce safe plumbing practices where they are needed most.”

Rademacher directs the Viega Trades Education Network, which partners with trade schools to provide tools, lessons and training to help educate future trades professionals.

This is only the latest industry honor for Rademacher. Last year, he was elected vice president of the board of directors of the American Society of Sanitary Engineering – International. In 2019, he won a World Plumbing Council Education and Training Scholarship to travel to Rwanda for the purpose of developing and contributing further plumbing industry knowledge. Also, he was the International Association of Plumbing and Mechanical Officials (IAPMO) Industry Person of the Year in 2014.

He has 30 years of experience in the industry and is an accomplished instructor. He is certified as a plumbing/mechanical inspector and plans examiner by the IAPMO. He has extensive experience using, implementing and interpreting the Uniform Plumbing Code, the Uniform Mechanical Code, International Plumbing Code, International Mechanical Code and International Fuel Gas Code.

Source Brewing is a destination, a place to enjoy a craft brew in a scenic location. And while you’re there, look overhead – you’ll see some Viega products adding to the décor. Located in Colts Neck, New Jersey, Source Brewing is in a 125-year-old converted barn. In trying to maintain some of the character of Read more

Source Brewing is a destination, a place to enjoy a craft brew in a scenic location. And while you’re there, look overhead – you’ll see some Viega products adding to the décor.

Located in Colts Neck, New Jersey, Source Brewing is in a 125-year-old converted barn. In trying to maintain some of the character of the barn, there are exposed beams.

Matt Fleming, Vice President of All Star Plumbing, knew he’d be running copper and carbon steel lines in the building. He also knew some lines would remain exposed, so he suggested Viega, because of its clean look and for several other beneficial reasons.

“The owners liked the look of it, with the exposed lines and such,” Fleming said. “When this job came up, I thought, ‘Let’s press everything in here and see how it goes.’

The flameless connection of Viega press technology was another benefit, since the crew was working in an old wooden structure. There was nothing to worry about, with no flame needed.

The brewery contains 12 tanks with glycol for chilling, and 2″ ProPress fittings were used on those copper lines. The 2″ carbon steel line feeding steam to three tanks was pressed with MegaPress fittings, and there are ¾″ branches from the tanks also done with MegaPress.

For the gas, a 1½” line equipped with MegaPressG fittings runs to the steam boiler. There’s about 100 feet of 1″ carbon steel line with MegaPressG fittings going to the mechanical room.

Mike Glaser, President of Aqua Solutions, installed the water filtration system for the brewery. Nearly all of his Annihilator Ultra Systems are installed with ProPress, and have been for the past decade. He said he uses Viega, because he knows he can’t beat the product.

“Viega is always consistent,” he said simply. “The fittings don’t break, they are reliable, and we don’t have issues with ProPress.”

“This is the first brewery that we’ve done everything with pressing,” Fleming added. “We’re realizing the time savings and efficiency, plus the lack of leaks. We’re not a big company, but we have five other brewery projects now on the forefront!”

The National Science Foundation’s Daniel K. Inouye Solar Telescope in Maui, Hawaii, uses the largest mirror of any solar telescope in the world. Thanks to its 13-foot-wide mirror, it collects seven times more sunlight than any other solar telescope, producing the clearest, highest-resolution images ever taken of the sun. Not surprisingly, a solar telescope of Read more

The National Science Foundation’s Daniel K. Inouye Solar Telescope in Maui, Hawaii, uses the largest mirror of any solar telescope in the world. Thanks to its 13-foot-wide mirror, it collects seven times more sunlight than any other solar telescope, producing the clearest, highest-resolution images ever taken of the sun.

Photos courtesy of NSO/AURA/NSF

Not surprisingly, a solar telescope of this size produces a lot of heat. With a working lifespan of about 50 years – after more than two decades of planning by the National Solar Observatory and its partners – there is a lot that goes into keeping the telescope cooled so it can provide groundbreaking scientific insights.

And that’s where Viega comes to the table.

An enormous, unique project

Eventually, there will be more than seven miles of thermal piping within the telescope and support buildings, explained Lou Szabo, Facility Thermal Systems Site Coordinator for the National Solar Observatory. He spends his days helping to finish construction and commissioning the equipment that recently began collecting images of the sun.

Much of the piping was prefabricated years ago, as various parts of the facility and telescope were being built (construction has taken about 10 years). Traditional methods, mainly welding, were used. But then the project came to a crossroads.

“As the various science instruments are installed and other devices added to the telescope, the final piping needs to be completed or modified, and oftentimes in close proximity to optics or one-of-a-kind electronics that are worth millions of dollars – things that would take many years to reproduce if damaged,” Szabo said. “We can’t have any joining methods that use heat or fumes. It has to be a very clean process.

“The only way to install these remaining piping runs is with a joining system that meets the ‘no heat, no fumes, no dust’ requirements – and Viega hit that mark. We can go into these critical areas with very little equipment and complete press joints within inches of sensitive equipment, and the crews don’t have to worry about damaging it.”

As the need for a press-fitting solution surfaced, Szabo was already aware of Viega. He’s been in the piping trades for more than three decades and had previously used Viega.

He also knew that Viega had a large variety of fitting choices and, more importantly, offered plenty of technical support.

“When I presented the press system to the lead engineers and the decision-makers, I had to bring the best system I knew of,” he said. “Viega had been around the longest and had the best technical support if we had a question or got into a bind. We knew we had the reliability of the system behind us. It was really the only choice. I wouldn’t have been comfortable with others.”

Another factor to account for is the ozone conditions. The telescope is located at Haleakalā Observatories, at 10,000 feet in elevation, on the island of Maui. This location allows for great conditions for observing the sun but brings with it other unique elements, too.

“There is a high ozone content in the atmosphere here. Ozone was attacking a lot of rubbers and things, so we use HNBR sealing elements in all of our fittings,” Szabo said. “Some of the coolants we use are more exotic, and the HNBR holds up.”

The bulk of the coolant used is Dynalene HC20. The manufacturer lists both HNBR and EPDM as compatible materials, but the EPDM seal isn’t as resilient with the ozone presence, so Viega’s HNBR sealing elements are the right fit.

Inner workings of the telescope site

A series of primary loops come from the main mechanical/utility building, where all the chillers are located. The loops run to heat exchangers, followed by secondary and tertiary loops. There are dozens of pumps and tanks involved in the complex setup.

Piping in the system includes everything from 6” carbon steel piping to ½” copper tubing. Stainless steel is also used. The miles of piping run coolants and air to keep the telescope project at an appropriate temperature and to keep everything working smoothly. Viega ProPress fittings up to 3” in diameter and MegaPress fittings as large as 2” are used throughout the site.

The mirrors and transfer optics are cooled in a variety of ways, including cooled liquid and air. For example, air a few degrees below ambient temperature is typically blown on the back of the mirror cells.

The Dynalene coolant runs at a very low temp, some as low as –2 degrees F, some around 45 degrees. The coolant is also environmentally friendly, which was important for the culturally sensitive site that carried with it many environmental guidelines. Propylene glycol mixtures are also used in some of the scientific chillers.

“A challenge we have in the middle of the Pacific is having fittings available, and that’s why we try to keep our setup as simple as we can,” Szabo said. “It’s also why we went with MegaPress and ProPress. Much of it is available on the islands, whereas other systems are more difficult to get.

“We try to keep a stock of certain fittings and materials on hand and stay ahead of the game. Oftentimes we’re looking at a two- to four-week lead time to get less-common fittings to the island. Thankfully our supplier, PACE Supply, can often get us common fittings within a couple of days.”

Szabo said they strive to keep the piping runs as simple as possible to both limit flow restriction and allow the use of standard elbows, adapters, tees and couplings, which are more readily available on the island.

One-of-a-kind solar research

Plans for the Inouye Solar Telescope (named for the late Daniel Inouye, the U.S. Senator from Hawaii who played a crucial role in getting finances approved for the project and was a big advocate of STEM and science) started 25 years ago. Dr. Claire Raftery, Head of Education, Outreach and Communication for the National Solar Observatory, said innovating how to build something so complicated – and then get it funded – was a massive undertaking.

There was an extensive survey done to determine the location of the telescope. A few hundred sites worldwide were reduced to a short list of 72, which was whittled down to a six. From there, only three met the specific requirements that scientists were looking for, and the location in Maui was chosen.

The Inouye Solar Telescope’s unique location combines clear and vivid blue skies needed to observe the faint corona of the sun with a high elevation and low air turbulence of the atmosphere above the telescope. Thanks to all these things, the telescope can produce the best images of the sun ever taken so that scientists can learn more about the dynamic star.

“We’re studying an object that there’s still a lot of mystery around. Many questions remain unanswered because we don’t yet have the capability to answer them,” Raftery said. “We need more detail, higher resolution – and these are things this telescope will bring to the table. It’s really a fortuitous time to be working in the solar physics industry.”

The telescope is expected to be operational for at least 44 years – four solar cycles – which is one of the benefits of ground-based astronomy, Raftery explained.

“We can expand the abilities of this project much longer than we could from space,” she said. “It’ll never really stop being finished. We can adapt and improve. The team will continue to bring new science experiments online through the life of the telescope.”

Part of the federal requirements from the National Science Foundation include returning the site back to the way it was found, so in 50 years they won’t simply turn off the lights and walk away, but instead the project will eventually be removed from the site after it has run its course.

But with that prospect decades into the future, for now everyone involved with the project is exhilarated as the telescope begins recording images of the sun.

“I remind the crews that they are the only ones in the entire world working on this unique system,” Szabo said. “This is truly a one-of-a-kind project.”