Solutions will Equip Trade Contractors with Powerful Tools to Run and Grow Their Businesses Mechanical Hub was onsite last week at ServiceTitan Pantheon 2023, its annual user conference, and if there was ever any doubt or fear that artificial intelligence (AI) was coming to the trades, Pantheon 2023 put those thoughts to rest. More Read more

Featured Articles

Solutions will Equip Trade Contractors with Powerful Tools to Run and Grow Their Businesses

Mechanical Hub was onsite last week at ServiceTitan Pantheon 2023, its annual user conference, and if there was ever any doubt or fear that artificial intelligence (AI) was coming to the trades, Pantheon 2023 put those thoughts to rest.

More than 1,500 service contractors, ServiceTitan team members and exhibiting partners spent three days exploring the “Journey to the Top” theme, which included more than 50 sessions to help contractors stay on track with next-level training, tools, and insights. In addition to the sessions, attendees enjoyed networking events, product plaza exhibit space, keynotes from industry VIPs and a closing fireside chat with tennis great Venus Williams.

“Over the past year, the world has seen a dramatic acceleration in AI advancements and ServiceTitan is making sure that the trades industry will be at the forefront of this technological revolution,” said Vahe Kuzoyan, president and co-founder at ServiceTitan.

To ensure Kuzoyan’s statement rang true, ServiceTitan introduced a suite of new products to empower residential and commercial contractors with groundbreaking technology to supercharge their businesses. Powered by Titan Intelligence, the company’s own AI solution purpose-built for the trades, these new cutting-edge solutions allow its customers to automate, predict, and optimize across their entire business.

Several of the new AI-powered products introduced at Pantheon include:

- Ads Optimizer maximizes the ROI of every dollar spent on an advertising campaign by educating Google Ads to focus on potential customers who are actively looking for service providers while avoiding users who aren’t. The feature also predicts which zip codes will have the most demand and automatically prioritizes ads for those specific locations.

- Dispatch Pro runs thousands of scenarios to get the right technician to the right job, allowing dispatchers to invest more time delivering a superior customer experience. Dispatch Pro’s algorithm also finds the best technician for every job based on the technician’s specific set of skills, recent sales performance, proximity to the job, and more – all to maximize profit.

- Integrated Financing gives contractors the tools they need to grow their business and protect their margins. The feature allows ServiceTitan’s customers to strategically control plans from multiple preferred financing providers on a single job, improving their customers’ approval rates. It also gives technicians confidence in offering plans that will ultimately win more high-value jobs easily.

- Second Chance Leads automatically detects unbooked phone calls from potential customers within minutes of the call ending, and specifically flags missed calls that the algorithm believes can be saved. The tool works in the background to identify missed opportunities, so ServiceTitan customers don’t have to.

“At ServiceTitan, AI means ‘Automated ROI,’” said Ara Mahdessian, co-founder and CEO of ServiceTitan. “We want to automate all the inefficient processes that steal precious hours away from contractors and their teams every single day, and at the same time provide actionable insights and powerful features to meaningfully grow their revenue. Our AI-powered tools allow our customers to focus their time and energy on what they’re best at, and most passionate about — solving problems for their customers and delivering the best quality service.”

While the session and networking was top-notch, Mechanical Hub was also selected as a session leader. They worked with Pfister Faucets and American Plumber Stories to present, ‘Building for Tomorrow: Recruiting & Retainment Tactics.’ The session highlighted Universal Plumbing’s Larry Jones, CEO and Shalanda Morris, Business Manager, and discussed their best practices finding, training and retaining employees. In addition, we looked for answers to address major roadblocks in recruitment, and shared some creative strategies to help contractors find their next rock star employee. A packed crowd of contractors also got to watch season four, episode one of American Plumber Stories.

Mike Prencavage Jr., owner of The Family Plumber, Los Alamitos, Calif., shared, “I attend pantheon for inspiration and motivation to grow my company. Being surrounded by great leaders and business owners in the industry does so much to rejuvenate my drive to succeed. AI will help streamline not only front office processes but also front line sales interactions. It’s important to never loose sight of the ‘customer experience’ and I feel that AI will only help to improve that high level of service. Servicetitans projected plans to incorporate these AI features are only going to help the industry and better the homeowners experience overall.”

For those that don’t use ServiceTitan and have never attened a Pantheon, it’s a learning and networking event for contractors of all sizes and experience in the home and commercial service industry. While most attendees are business owners, managers, IT professionals, or members of the finance team, all trades professionals are invited and encouraged to attend.

ServiceTitan was founded in 2007, and helps residential contractors manage a range of tasks including booking jobs, dispatching technicians, processing payments and overseeing marketing campaigns.

Mary-Anne Bowcott (@the_ladyplumber) is a testament to perseverance and hard work. In a male-dominant industry, now a successful business owner, she is blazing the trail for women to look at trades in a different light. Mary-Anne Bowcott has come a long way from the days of living on a farm— which housed a few hundred Read more

Mary-Anne Bowcott (@the_ladyplumber) is a testament to perseverance and hard work. In a male-dominant industry, now a successful business owner, she is blazing the trail for women to look at trades in a different light.

Mary-Anne Bowcott has come a long way from the days of living on a farm— which housed a few hundred birds, larger livestock, but mostly poultry—to the 4H program where she would show her chickens and ducks.

Born and raised on southern Vancouver Island, Mary-Anne Bowcott was a near straight-A student, who, by her own admission, was kinda awkward, a bit weird, and wasn’t one of the pretty girls in school, and she was bullied pretty hard. As a result, she dropped out in grade 11. Around the same time, her parents were mid-divorce and, “I decided that in my infinite wisdom at almost 16 years old, I would get a job at Wendy’s and move out on my own. I partied, got into a lot of trouble, struggled with addiction, and going for a doctoral degree went out the window at that point,” says Bowcott.

After a couple of years, Bowcott decided to smarten up. She went back to school and got her grade-12 equivalency—the youngest student in an adult class; they almost didn’t let her in because she was too young. “I slayed that with flying colors but still didn’t know what I wanted to do,” says Bowcott.

After a couple of years, Bowcott decided to smarten up. She went back to school and got her grade-12 equivalency—the youngest student in an adult class; they almost didn’t let her in because she was too young. “I slayed that with flying colors but still didn’t know what I wanted to do,” says Bowcott.

Bowcott recalls going on a date with a guy who owned a construction company and she mentioned how sweet it would be to get into construction, but at that time, it was an unrealistic option for women. “His response was, ‘Why don’t you?’ That got the wheels turning and I started handing out résumés at that time.”

It was a struggle to find employment at the time as being petite female teenager, says Bowcott, as employers didn’t exactly take her very seriously. She had no call backs on her résumés, and, in fact, she almost took her first name off of the resume so she would have a chance. Finally, Bowcott asked her friend’s uncle who owned a roofing and renovation company to hire her, and he did. She landed her first job in the industry as a roofing laborer. She worked that job, and a couple different companies for a few years, quickly working her way up to her boss’s lead hand on commercial and residential jobs. “I got bored of it after starting commercial, as we were stuck on the same jobs for months at a time. The spotty work during the winter months were hard too on the bank account so I started looking for other options at this point.”

Bowcott eventually, through more pestering, landed a plumbing apprenticeship and never looked back after that. “Honestly though, it was hard making the transition, as again, no one took you seriously even though you were in the construction industry. Yes, I had made a name for myself, but only in the roofing community, so switching out was like starting all over again.”

Now a 19-years veteran of the construction industry, a shingle roofer, Red Seal journeyman Plumber, Class B gas fitter and successful, award winning plumbing and gas business owner, “I hope that I can help pave the way for young women seeking a career in the building trades, showing first hand that you can do whatever you set your mind to with a little persistence, motivation, determination and a whole lot of pestering.”

Now a 19-years veteran of the construction industry, a shingle roofer, Red Seal journeyman Plumber, Class B gas fitter and successful, award winning plumbing and gas business owner, “I hope that I can help pave the way for young women seeking a career in the building trades, showing first hand that you can do whatever you set your mind to with a little persistence, motivation, determination and a whole lot of pestering.”

It shouldn’t go without noting that Bowcott often times censors her career path story, leaving out the dropping out of high school and getting into trouble. She is not ashamed or shy about how she got into construction. “I just don’t want high school students to drop out because they see someone who did, and then become successful. On the other side, I’ve also done public speaking on the fact that one can hit rock bottom, be mixed up in addiction and bad situations and still come out on top,” says Bowcott.

Fast-forward to 2023 and for the past eight years, Bowcott has been the proud owner of Westcom Plumbing and Gas Ltd, as well as Westcom Roofing and Sheetmetal, on Vancouver Island, British Columbia, Canada. The plumbing company specializes in plumbing repairs, service, drain cleaning, renovations, gas service, repairs, retrofit and light commercial.

Fast-forward to 2023 and for the past eight years, Bowcott has been the proud owner of Westcom Plumbing and Gas Ltd, as well as Westcom Roofing and Sheetmetal, on Vancouver Island, British Columbia, Canada. The plumbing company specializes in plumbing repairs, service, drain cleaning, renovations, gas service, repairs, retrofit and light commercial.

She finds the work particularly rewarding. “I really enjoy working with my hands and feeling like I’ve achieved something, helped someone, or made some sort of difference,” says Bowcott.

She always has been crafty, and coming from an artistic family, creating things has been something she’s done since she was a child. With plumbing and gas though—roofing as well—we are out there helping people, and she loves that. “Yes, the money is good, but it was never about that for me. It’s always been about helping and creating.”

Starting A Business

She knew she was ready to start her own company when she injured her back and almost went back to school to do hair. “But I couldn’t fathom going from my journeyman wage to minimum wage, especially with a mortgage,” says Bowcott.

“My husband and group of women I knew suggested why not start my own company? That way I could pick and choose the jobs I could do with the injury. I was at that time a new construction plumber and it wasn’t uncommon to do a full 7-10 days of straight groundworks. So, I quit my job and opened up my own company, and it was the best decision I have ever made.”

Nevertheless, as a woman-owned company in a male-dominated industry, Bowcott did have some anxious times, worried about work coming in. “I actually didn’t even put my name on my business card in fear that people wouldn’t hire me because I was a woman. I was wrong of course.

Nevertheless, as a woman-owned company in a male-dominated industry, Bowcott did have some anxious times, worried about work coming in. “I actually didn’t even put my name on my business card in fear that people wouldn’t hire me because I was a woman. I was wrong of course.

“There are people that don’t hire us because we are women, but we wouldn’t work for them anyway with that attitude. I kept the name of the business neutral as well to hide the woman factor. But honestly, I’m from a small town where everyone already knew me from growing up there, and as soon as I opened the company, like I mean day 1, I’ve been slammed busy. I didn’t advertise. I still don’t advertise. It’s all been word of mouth.”

Talking about being a female in this industry, Bowcott says she definitely tries her best to be a mentor for as many women as possible. Or men if they want, “but we don’t really get those calls lol.”

“I used to be more involved with non-profits and local groups, but I took a step back—as it was getting super time consuming and a lot volunteer work—to focus more on my business as well as social media as I seem to reach more women on social media than I did before.”

The Social Connection

And because of social media, many doors have opened, more than Bowcott thought imaginable. “Being able to go to the RIDGID Experience 2022, going to conventions and trade shows and hanging out and becoming friends with the plumbers that you have followed for years, the supportive messages and the messages of people needing mentoring or advice, or simply messaging to say that I made a difference in their life as an inspiration to them is truly heartwarming,” says Bowcott.

And because of social media, many doors have opened, more than Bowcott thought imaginable. “Being able to go to the RIDGID Experience 2022, going to conventions and trade shows and hanging out and becoming friends with the plumbers that you have followed for years, the supportive messages and the messages of people needing mentoring or advice, or simply messaging to say that I made a difference in their life as an inspiration to them is truly heartwarming,” says Bowcott.

“I am so grateful for the opportunities that have been dropped at my doorstep for simply taking a video or picture of what I did that day. And not that I needed to advertise, but I know a lot of my clients have called because of what they have seen on social media. They get to see what type of work you’re putting out there which really helps.”

“I am so grateful for the opportunities that have been dropped at my doorstep for simply taking a video or picture of what I did that day. And not that I needed to advertise, but I know a lot of my clients have called because of what they have seen on social media. They get to see what type of work you’re putting out there which really helps.”

Personal Touch

As far as downtime, what does Mary-Anne like to do to decompress? ““I don’t decompress haha. I rock climb, do Crossfit, personal training, surf, park roller skating, and I also clean my van at any opportunity if there’s something out of place. I try and do as much as possible at home before its time to make dinner. My days are long and exhausting, I can’t sit still, I don’t relax, I’m always on the go, and I wouldn’t have it any other way.”

As well as hurting her back, she struggled with severe knee pain from, you guessed it, roofing and plumbing, and she actually thought she was going to need a knee replacement by 40. She met with a local athletic therapist and he said that if she didn’t do some sort of weight training to strengthen areas that needed it, her body would “implode by 40.” “S“So, I started at my local Crossfit gym, and shockingly after 2-3 months, I had zero knee and back pain. So, I am a believer. I now work out around 4-5 days a week depending on how busy I am.”

As well as hurting her back, she struggled with severe knee pain from, you guessed it, roofing and plumbing, and she actually thought she was going to need a knee replacement by 40. She met with a local athletic therapist and he said that if she didn’t do some sort of weight training to strengthen areas that needed it, her body would “implode by 40.” “S“So, I started at my local Crossfit gym, and shockingly after 2-3 months, I had zero knee and back pain. So, I am a believer. I now work out around 4-5 days a week depending on how busy I am.”

Though she already travels a lot, there’s a few items pending on her bucket list: going to Morocco, going to Turkey, skydiving, an Indonesian boating/surf trip, and a trip to Tahiti.

If you ask Bowcott about her tattoos, she’ll tell you she made a lot of poor tattoo choices in her younger days. “My first was a tattoo in a hotel room when I was 16 by a pretty dodgy character. Thank God I didn’t end up with a disease after that one. It was supposed to be a fairy, but ended up looking like a gremlin trying to bang itself with its foot. I got it covered up with a tiger on a waterfall landscape, but I hated that too as it was definitely too cartoonish. I ended up getting 12 laser treatments on it and finally found someone to cover it up, and that’s when I got the tiger on my back, which I’m super happy with.”

If you ask Bowcott about her tattoos, she’ll tell you she made a lot of poor tattoo choices in her younger days. “My first was a tattoo in a hotel room when I was 16 by a pretty dodgy character. Thank God I didn’t end up with a disease after that one. It was supposed to be a fairy, but ended up looking like a gremlin trying to bang itself with its foot. I got it covered up with a tiger on a waterfall landscape, but I hated that too as it was definitely too cartoonish. I ended up getting 12 laser treatments on it and finally found someone to cover it up, and that’s when I got the tiger on my back, which I’m super happy with.”

What’s next? Bowcott tries to live her life as each one is her last and she tries to experience as much as possible, “because you really don’t know when you’re gonna go and I want to make sure I do as much as I can before that day. My husband’s best friend passed away a few years ago at 50 and it really buggered me up. Ever since then, my life has been nothing but trying to do it all NOW!”

In the Tool Bag

RIDGID end 190” wrenches, adjustable wide mouth Crescent, RIDGID 154 quick acting tubing cutter, Stanley tape measure, Milwaukee flip knife, a Himor HVAC multi-tool, and a hacksaw.

In the Van

Milwaukee portable band saw, Milwaukee oscillating tool, Milwaukee Hackzall, grinder and Fuel Packout vacuum, and a Hilti jackhammer.

Greetings everyone out there in Radio-land, and welcome to our show, Everything You Always Wanted to Know About Air-To-Water Heat Pumps* (*but were afraid to ask). Our hosts John Barba, Director, Sales Training NA, Taco, and Dave Holdorf, Product & Application Instructor – East, Taco, both of whom have a face for radio, are here Read more

Greetings everyone out there in Radio-land, and welcome to our show, Everything You Always Wanted to Know About Air-To-Water Heat Pumps* (*but were afraid to ask).

Our hosts John Barba, Director, Sales Training NA, Taco, and Dave Holdorf, Product & Application Instructor – East, Taco, both of whom have a face for radio, are here to take your questions and, if a miracle occurs, provide you with coherent answers.

And now, here are your hosts, direct via satellite from Cranston, Rhode Island – John and Dave!

John: Thank you everybody, and welcome to our show. I’m John and on the other microphone is Dave. Say hello, Dave.

Dave: Hello Dave.

John: Yep, those 11 semesters at the Connecticut School of Broadcasting are really paying off, aren’t they? Let’s get right to your calls and tackle some questions on Air to Water Heat Pumps. Dave, who’s our first caller?

Dave: First up JB, we have Elliot from Kansas City. Elliot, you’re up. What’s your question?

Caller: Hi, this is Elliot from Kansas City. Am I on?

John: Hi Elliot, you’re live, coast to coast. There are literally tens of people waiting on your question.

Caller: Wow. Tens, huh?

Dave: Okay, maybe dozens. So . . . what’s cookin’ Elliot?

Caller: Well, it’s pretty basic, but – how many BTU’s? What size house can I do with an air to water heat pump?

John: That’s a great question, Elliot. We get more calls about that than anything else. First, understand that any air-based heat pump extracts heat from the air using a refrigeration cycle. And it stands to reason that the colder it gets outside, the less heat there is in the air to, you know, extract.

Dave: That’s correct, JB. So as it gets colder out, the actual output of an air-to-air or an air-to-water heat pump goes down. So when you need more heat, the heat pump is actually producing less heat.

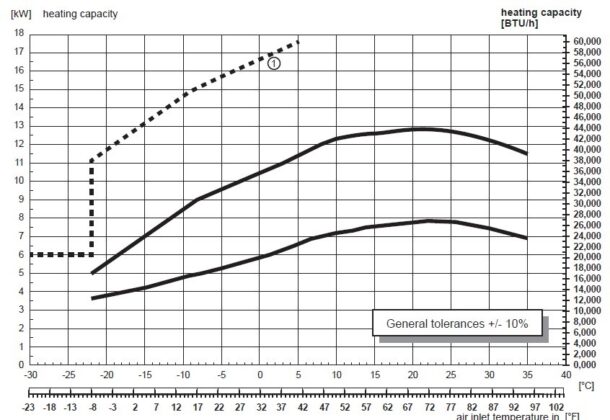

System M output chart:

Taco System M, air to water heat pump, heat pumps, heat pump technology, electrification, heating and cooling, plumbing HVAC

John: As you can see from this output chart for the Taco System M, as the outdoor temperature drops, so does the heat pump’s ability to produce BTUs for heating…

Dave: Uhhh, boss . . .

John: It drops off pretty sharply, as you can clearly see from this chart I’m showing you. When you hit 0o F, the output of the heat pump unit itself is about 21,000 BTUH . . .

Dave: Boss . . .

John: And when it hits its low limit of -7o F, its output is only around 17,000. It’s right there, plain as day.

Dave: Boss . . .

John: WHAT?!

Dave: It’s radio, they can’t see the chart.

John: Oh, right. Sorry. Anyway, that’s the case with any air-source heat pump. That’s why System M also includes a 6kW immersion heater in the buffer tank in its companion indoor unit, the HydroBox. That heater adds another 20,478 worth of potential output to the unit, for a total of just under 38,000 at -7o F.

And don’t fret about the immersion heater coming on willy-nilly. It’s intelligently controlled.

Dave: Willy-nilly?

John: It’s an industry term. Who’s our next caller?

Dave: We have Kyle on the line from the alliterative metropolis of Saskatoon, Saskatchewan.

Caller: Greetings, eh? It can get pretty frosty up here in Saskatoon. Can we hook up some backup heat for when it hits 40 below?

John: Gotta tell ya, my favorite Guess Who song ever is “Runnin’ Back to Saskatoon.” I love how it mentions all those great Saskatchewan towns, like Red Deer, Hanna and Medicine Hat.

John Barba

Caller: Uh, those towns’re in Alberta. Maybe I could talk to Dave instead?

Dave: I got ya, Kyle. It’s very easy to incorporate a backup or auxiliary heat source with an air-to-water heat pump. If the heat produced by the 37,000-plus BTUH System M at -7o F isn’t enough to heat the home, you can have the auxiliary heat come on at -8. Or, let’s say the heat pump/immersion heater combo comfortably heats a home at 10oF above with a total output of 46,000 BTUH, but it can’t take care of the load once it gets colder than 10oF. Then you can set up an auxiliary heat source – like a gas-fired mod-con – or, if the area isn’t allowing any new fossil fuel burning equipment, an electric boiler could meet that need. It’s actually a simple, single pole-double throw switch activated by outdoor temperature. It turns the heat pump off and turns the boiler on.

John: Great answer Dave. That’s exactly what I was going to say.

Dave: Yeah, but you were still runnin’ back to Saskatoon like the McKenzie Brothers. Let’s go to our next caller, Eric in Minnesota. Go ahead Eric:

Caller: (silence)

John: Eric, what’s your question?

Caller: (silence)

Dave: Welp, Eric’s not here. Let’s move on to Pete from Colorado. What’s up, Pete?

Caller: Hi guys. Long time listener, first time caller. Simple question: how does an air-to-water heat pump switch from heating to cooling?

John: Excellent question Pete. There are lots of ways to do it, ranging from a manual switch combined with turning a bunch of valves on and off, to a simpler, control-based solution.

Dave: That’s right, Boss. An integrated control, like the one with the Taco’s System M, uses an outdoor sensor. Based on the type of home, the climate and the level of insulation in the house, you can program an outdoor temperature at which the system goes into heating mode. Let’s say it’s 53 degrees. You can also program in the temperature at which the system goes into cooling mode. Let’s say that’s 63 degrees.

John: Remember gang, these are just examples. But Dave, if you go into heating mode at 53 oF and cooling mode at 63 oF, wouldn’t that leave a sizable dead band between the two?

Dave: Right you are, Sunshine. In that dead band, System M doesn’t do anything except maybe make domestic hot water if you need it to. If you need cooling and it’s 62 or 63 degrees, you can cool with the reserve of chilled water in the buffer tank. By the same token, if you need heating when it’s 54 or 55 degrees, you’ll have heated water in the buffer tank.

And if you have a houseful of people over for a spring holiday and you’re in the dead band, you can go into a forced cooling mode if you want to.

John: Awesomeness! We have two callers on the line now Dave, and both have the same question. Drake from Idaho and Tom from New Hampshire both want to know how an air-to-water heat pump can make domestic hot water when the heat pump itself is in cooling mode.

Caller: Yeah, this is Drake. I’m with that Tom guy. It doesn’t make sense that an air-to-water heat pump can make heated water for the indirect hot water tank and chilled water for cooling at the same time.

Caller: Yeah, this is Drake. I’m with that Tom guy. It doesn’t make sense that an air-to-water heat pump can make heated water for the indirect hot water tank and chilled water for cooling at the same time.

Dave: Great observations guys, and you’re correct. An air-to-water heat pump can’t make heated and chilled water at the same time.

Caller: Yeah, this is Tom. That Drake fellah is wicked smaht to ask that question. How can you make the watah hawtt when the freakin’ heat pump is making cold?

Dave: That’s where a buffer tank becomes really important. Let’s say the heat pump is in cooling made. With System M you’ll have a 30 gallon buffer tank filled with chilled water. When the indirect domestic water heater calls to make more hot water, the heat pump immediately jumps into heating mode.

Since you want to make hot water as quickly as you can, you can’t really wait for the 30 gallons of chilled water to be used up. And we don’t want the heat pump to turn all that chilled water into hot water. It would take forever and it’s not exactly what you’d call “green.”

John: Right you are, Dave. That’s where the piping in the System M indoor unit – what we lovingly refer to as the “HydroBox” – comes in. The piping arrangement in the HydroBox is called – are you ready? – a dual differential pressureless manifold. Its job is to hydraulically separate the heating and cooling piping circuits from the buffer tank-heat pump piping circuits. In addition, it also isolates the indirect DHW tank piping from both the heating and cooling circuits.

Dave: Exactamundo, my man. So when the indirect calls to make DHW, the heat pump itself goes right into heating mode, and the hot water from the heat pump bypasses the buffer tank altogether and goes direct to the indirect. The cooling circuit, meanwhile, can still run using the 30 gallons of chilled water that’s still in the buffer tank.

Caller: But won’t that water heat up quickly?

John: It’ll heat up over time, which means two things. First, the best applications for air-to-water heat pumps are very well insulated homes (think steroidal insulation) that don’t heat up or cool down quickly. That buys you time.

Dave: Additionally, you can program the unit to regenerate the hot water tank at specific times. Maybe the best time to do it during cooling season is at night when you’re asleep. You’ll be less likely to notice any temperature creep.

John: Wow, will you look at that. The old clock on the wall says time is up for this week’s edition of Everything You Always Wanted to Know About Heat Pumps* (*But Were Afraid to Ask). Thanks for being with us.

Dave: And if you enjoyed this show, make sure to join John and myself online during the spring and summer on Taco After Dark, our weekly nighttime program dedicated to all things hydronic, plumbing and heat pumps.

The fun starts once the sun goes down!

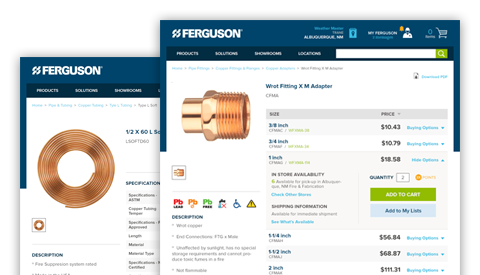

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource. As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover Read more

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource.

As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover, running a successful plumbing business requires access to quality products, reliable suppliers, and expert advice. In today’s digital age, having a robust online platform can significantly streamline your operations and contribute to your business’s growth.

In today’s post-COVID world, especially dealing with disruptive supply chain issues, it almost goes without saying; you can never have too much inventory on the truck or back at the shop. That’s why I rely on Ferguson.com, a comprehensive website that has plumbing contractor-specific resources available, all of which are literally just a click away. And that click provides real-time stock and pricing of more than 200,000 HVAC and plumbing products; I can see what’s in stock and my contract pricing.

My plumbing business relies on my wholesaler to carry a vast range of top-quality products from leading brands, and I trust Ferguson to provide those trusted, reliable, and durable solutions. Whether I’m looking for pipes, fittings, valves, fixtures, boiler parts or specialty items, I look to Ferguson.com.

Some really helpful features include “My Lists.” I am able to customize the order process with just a few clicks, instead of individually searching for the products I purchase regularly and organizing lists of the products I want. This ultimately has saved me time and has helped to streamline my ordering process. Ferguson.com even gives me the ability to share those lists I’ve created and keeps products I purchase under the “Bought Often” tab, which is automatically updated monthly.

The Quick Tools feature is a shortcut that makes it easy for trade professionals to quickly access other popular site features. It gives me the quick ability to order, reorder, find an order, or turn existing quotes into orders, all in one place. In some cases, I can even order online and have the order ready in an hour with Pro Pick-Up 1 Hour (at locations where Pro Pick-Up 1 Hour is available).

While traditional brick-and-mortar purchasing is still a viable wholesale solution, with Ferguson.com, I can gain access to a seamless and convenient online ordering system. This allows me to browse through products, check availability, compare prices, and place orders anytime, from anywhere. By simplifying the procurement process, Ferguson.com saves valuable time and effort, enabling me to focus on serving my customers better.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Sometimes I need to know what was on an order or the last time I bought a certain product. I’m able to find all of that online and end any confusion about my orders. If I need to see the status of an order, I can see it on my Ferguson Dashboard or Orders, and even get the proof of delivery. (Proof of delivery may not be available depending on how the order shipped or if it was signed for.)

Forward Thinking

Ferguson understands the importance of competitive pricing for plumbing contractors. By signing up for a Ferguson.com account, one can unlock access to exclusive contractor pricing on a wide range of products. This ensures that I can offer my customers competitive rates while maintaining healthy profit margins for my business. The savings one can achieve through Ferguson.com can significantly impact your bottom line and give you a competitive edge in the market.

It’s pretty simple, really. Creating an account on Ferguson.com provides plumbing contractors with a range of powerful tools to manage their business efficiently. By logging in, one can track his or her order history, access invoices, and manage one’s account settings, all in one centralized location. This streamlined account management feature eliminates the need for tedious paperwork and enables one to stay organized and in control.

What’s also cool about the site is that I can enroll for the free PRO Plus™ program. After I enrolled in this program, I now earn one point for every dollar I spent online. I can then redeem those points for cool prizes and earn Bonus Points faster by purchasing featured products. PRO Plus™ customers are also eligible for discounts with select businesses.

Ferguson.com boasts an extensive inventory of plumbing products, tools, and supplies, as well as expert advice and efficient account management, making it a one-stop solution for all of my business needs. By utilizing the features and capabilities of Ferguson.com, I can streamline my operations, relieve operational stress, and propel my business toward greater success. Sign up today and unlock a world of opportunities for your plumbing contracting business with Ferguson.com.

In the six years since its inception, Women in Energy (WE) has grown rapidly, providing women a variety of opportunities to strengthen their skillset and knowledge base as it relates to their careers in the energy, heating and cooling industries. The organization now has 500 nationwide members and is on a steady growth trajectory. It’s Read more

In the six years since its inception, Women in Energy (WE) has grown rapidly, providing women a variety of opportunities to strengthen their skillset and knowledge base as it relates to their careers in the energy, heating and cooling industries. The organization now has 500 nationwide members and is on a steady growth trajectory.

In the six years since its inception, Women in Energy (WE) has grown rapidly, providing women a variety of opportunities to strengthen their skillset and knowledge base as it relates to their careers in the energy, heating and cooling industries. The organization now has 500 nationwide members and is on a steady growth trajectory.

It’s worth mentioning that WE is not exclusive to women, and neither are its myriad learning and networking opportunities. Its mission, to connect and empower women working in the energy industry, extends to anyone looking to improve themselves and make an impact on the industry.

WE provides career resources, creates networking and mentoring opportunities, offers online and in-person educational courses and develops strategies to minimize obstacles women may face in the industry. The organization hosts an annual conference, weekly webinars, regional networking events, an upcoming golf outing, and now, a new online learning center called the learning portal, called the E-Learning Library, launched in September 2022.

“With all of our recorded Webinar Wednesday sessions, our educational library has grown to be pretty expansive,” said Judy Garber, WE Executive Director. “We’ve consolidated all of this content in the easy-to-access E-Learning Library on the WE website. Members can access this material wherever and whenever they wish.”

The material covers everything that someone relatively new to the industry – or someone who just changed positions – may benefit from; soft skills, leadership, legal, technical, personal development, etc. At one WE meeting feedback from participants suggested that basic information on various types of energy and HVAC technology was needed.

“We love identifying needs and providing meaningful solutions,” said Erin Holohan Haskell, WE President. “For instance, some of our members in marketing and customer service roles expressed an interest in learning more about the technical aspects of our industry to better assist their customers and expand their knowledge. This feedback gave us real direction in regard to the learning opportunities we wanted to create next.”

As a result, WE developed material on a wide variety of energy technologies. A small sample of the courses offered include Residential Heating 101, Heating System Basics, Biodiesel and Renewable Diesel 101, Heat Pumps 101, Introduction to Solar, Wind Energy 101, and Geothermal Basics.

The E-Learning Library is a great resource for business owners and managers to bring new employees up to speed, or for members to learn on their own.

“We realize that professionals are busy and may not be able to attend our live Webinar Wednesdays or in-person programming,” said Holohan Haskell. “This gives them the opportunity to access valuable content on their own timeline. And there’s content for everyone; those who are new to our industry as well as more experienced professionals.”

“One of the great joys I’ve found in working with WE is that we can move quickly to answer a need,” continued Holohan Haskell. “We’re small and new enough to be nimble. We think ‘what if?’ and then make ‘what if’ happen. In reality, that’s how WE was founded, and we’ve continued doing that. For a small organization, we’ve managed to get a lot done in a short time, thanks to the strong leadership of Judy Garber and a very engaged group of officers and members.”

(Left to right) Jacqueline Aceituno accepts the Judy Garber Rising Star Award from Judy herself. Photo Credit: Andrew Frongillo

The rapid growth exhibited by the organization speaks to the need for the resources that WE provides.

Benefits of annual membership far outweigh the $75 individual member investment. In addition to unlimited access to training, membership includes discounts to events, access to networking opportunities, mentorship, etc. Various levels of WE membership are available, from individual to a tiered corporate structure.

“We encourage people interested in WE to attend our annual conference or one of our other events,” said Garber. “These events are engaging, fun, and offer a great opportunity to see what we’re all about.”

The 2023 WE Conference will be held in Hershey, PA, from September 20 through 22. Also, WE’s second annual golf tournament will be held on October 9, 2023, at the Hershey Country Club.

“Business relationships are often strengthened on the golf course, but we’ve noticed that women often sit out of industry tournaments because they’re unfamiliar with the sport,” said Holohan Haskell. “WE is dedicated to providing our members with career resources to help them succeed in business, so we partnered with the Pennsylvania Petroleum Association on a tournament for golfers of all skill levels.”

(Left to right) Gary Cooperrider, Rosemarie Bartchak and Erin Holohan Haskell during a WE networking reception Photo Credit: Marjorie Feinman

Before the tournament begins, WE hosts an instructional session with a golf pro for those interested in learning the basics. If members are unfamiliar with golf, this was the perfect opportunity for them to learn the sport so they can participate in future networking opportunities on the golf course.

There are also numerous regional events held throughout the year. These events can be found listed at the WE website. For more information, please visit www.wewomeninenergy.com. The E-Learning Library can be accessed at E-Learning Library – Women in Energy (wewomeninenergy.com).