According to a recent study by Global Market Insights, the air source heat pump market value is projected to cross $77 billion by 2028. Increasing demand from growing real estate sector along with soaring requirement of space heating applications across colder regions will encourage the product deployment. Air to water source heat pumps segment is Read more

Featured Articles

According to a recent study by Global Market Insights, the air source heat pump market value is projected to cross $77 billion by 2028. Increasing demand from growing real estate sector along with soaring requirement of space heating applications across colder regions will encourage the product deployment.

Air to water source heat pumps segment is anticipated to witness a noteworthy growth owing to various features including simple design and easy installation, says the report. Rising global temperature and growing green building construction will provide positive drivers for product deployment. Integration with solar heating source and hence low input cost for product across temperate countries will drive the space heating systems demand in the forecast timeline.

Lochinvar’s air source heat pump water heater

The movement towards electrification—moving away from fossil fuel—seems to be the main driver of the heat pump movement. “I think consumers see an option to add PV, or join a solar garden, to become more energy independent. So having a heating, cooling and DHW option powered by your roof makes some sense. The rise in fossil fuel prices, uncertainty around supply certainly adds some motivation to look at heat pumps,” says Bob ‘Hot Rod’ Rohr, training manager, Caleffi, and former hydronic contractor of more than 30 years.

Recently, Mechanical Hub spoke with Arthur Smith, Residential Product Manager, A. O. Smith, and Jennifer Russell, Segment Development Manager, Decarbonization, Lochinvar, to get the latest on heat pump technology and heat pumps water heaters.

MH: What are some of the driving forces behind this technology?

Arthur: At A. O. Smith, we’ve seen two major driving factors behind the increasing popularity of residential heat pump water heaters. First, as consumers have begun to see wider availability of this technology, along with its carbon emissions reduction and tremendous cost savings, they’ve pushed to utilize heat pump water heaters in their own homes, further increasing demand. The second driving factor we’ve seen is the evolving regulations around decarbonization. These changes have placed an emphasis on heat pump technology as an excellent option for greenhouse gas reduction.

A. O. Smith’s CHP-120 heat pump water heater

Jennifer: On the commercial side, greenhouse gas emission reduction is the main driving force behind the increase and development of heat pump technology. However, due to the lack of availability of commercial heat pump technology, we don’t see it utilized in applications as often as the residential sector. In addition to state and local reduction goals, there are also many companies and building owners who are setting their own goals for reducing greenhouse gas emissions and they’re seeking out heat pump water heaters as a way to meet those goals.

MH: What are the benefits of heat pump technology?

Arthur: The core benefit of heat pump water heaters is the massive jump in efficiency. High efficiencies drive cost savings, which is a huge benefit to homeowners.

Jennifer: One of the main benefits of heat pump technology is that there are zero direct carbon emissions from the unit. For any commercial building looking to decrease its environmental impact footprint, this technology can play a big role in meeting those goals. In addition to the environmental benefits, heat pump technology is also incredibly efficient, providing an average annual efficiency of 200-300%.

MH: Do you see demand for heat pumps more on the residential side than commercial? What is the ratio?

Arthur: Overall, we’ve seen significant interest in both commercial and residential applications.

Jennifer: At Lochinvar, we’ve seen interest in both commercial and residential applications. Interest in ommercial applications for heat pump water heaters has grown significantly in the last couple of years, primarily due to evolving state and local environmental regulations.

Can the grid support a heat pump transition?

Arthur: The grid has been able to support the transition so far, but as heat pump technology continues to increase in popularity, developing the grid will need to be prioritized. It seems that most regulators are aware of this need to develop the grid and are building their regulations accordingly so the grid isn’t overwhelmed.

Jennifer: While the grid may be able to support a heat pump transition eventually, it can’t happen overnight. It’s going to take many years to fully develop a grid that can support a full transition to heat pump technology. In the meantime, we can develop and implement tools, such as demand-response technology, to help support the transition.

Commercial Heat Pump Water Heater

MH: Is a different skill set required for installation?

Arthur: On the residential side, there isn’t a different skill set required for installation. A. O. Smith designed our residential heat pumps so they can be installed in almost the same way as our standard electric water heaters. There are still some minor considerations, like draining non-acidic condensate produced by heat pumps and differing space requirements, but overall, the installation process is nearly the same as what most contractors are familiar with now.

Jennifer: There isn’t a different skill set required for installation, but there is unique training that can better prepare someone to install or service heat pumps. Heat pump water heaters have features that differ from traditional water heaters and these features require different training. Lochinvar offers training to help educate on the unique application features of heat pump technology.

MH: What is the life expectancy compared to boilers?

Arthur: Our heat pump water heaters are built to the same quality standards as all A. O. Smith products. We put care into developing products that perform well throughout their lifetime. We’re confident in our products and offer a standard 10-year limited warranty on every heat pump we produce.

Jennifer: You’re not going to see any loss of life expectancy with heat pump water heaters. They’re designed to hold up and perform as well as other water heating technology

MH: Do you offer training for these products?

Arthur: Since residential heat pump technology has been around for a bit longer than commercial, we’ve had time to develop training resources that focus on the installation and servicing of these units. A. O. Smith University offers digital live training at www.university.hotwater.com and there are courses available that focus specifically on heat pump technology.

Jennifer: At Lochinvar, we offer training resources to educate sales reps, engineers, contractors and technicians on heat pump technology. At the moment, our heat pump training focuses on topics such as applications for heat pumps, ensuring the correct unit size specification and understanding the technology’s benefits and features.

The Grand Opening of Rinnai’s RAM Lakes Facility in Griffin, Ga., featured the first non-condensing tankless—the first of many salable units— manufactured here in the states. At approximately 6:15 am on a crisp Tuesday morning, Rinnai America Corporation made history in the United States, and all of North America. At its new 300,000-sq.-ft RAM (Rinnai Read more

The Grand Opening of Rinnai’s RAM Lakes Facility in Griffin, Ga., featured the first non-condensing tankless—the first of many salable units— manufactured here in the states.

President, Rinnai America Corporation, Frank Windsor puts his John Hancock on the first unit manufactured at the RAM Lakes facility in Griffin, Ga.

At approximately 6:15 am on a crisp Tuesday morning, Rinnai America Corporation made history in the United States, and all of North America. At its new 300,000-sq.-ft RAM (Rinnai America Manufacturing) Lakes facility in Griffin, Ga., the first—of many non-condensing tankless water heaters—rolled off the line. On April 21, 2022, the Griffin facility completed the production of its first tankless water heater, a unit of the highly anticipated RE Series, the first and only non-condensing unit with a built-in pump and SmartCirc intelligent recirculation technology.

“This is a significant milestone for our company and corporation. We are here to celebrate not only becoming the first major tankless manufacturer in the North American market to invest in domestic manufacturing,” said Frank Windsor, President, Rinnai America Corporation. “But we are also launching a brand-new product here today, which will become a really compelling product we bring to market.”

On April 21, 2022, Rinnai held a festive Grand Opening at its RAM Lakes facility.

“This morning, the first RE Series tankless water heater came off the end of the line,” said Shelley Kiley, Vice President of Operations. “The day has arrived that we are going to produce our first salable RE Series tankless hot water heater and we are so excited. Over the last two years, it’s been a challenge for the entire team. They worked tirelessly through a lot of challenges, obviously covid, global supply chain issues, escalation of pricing of materials for the construction of this and I would say that the whole team is really proud that they came within 4% of budget and only six weeks of delay on the entire project from start to finish,” said Kiley.

Throughout the new facility, Rinnai definitely puts its money where its mouth is as you’ll find fully operational tankless units humming beautifully throughout, like this SENSEI RSC199iN.

In 2017, the global organization recognized the significant potential for this market and made the decision to invest in Rinnai America to become a growth vehicle for the corporation. According to Windsor, this has been a substantial investment over the last three or four years—a new corporate headquarters in Peachtree City, which was an $18 million dollar investment, a $10 million investment in our new world class innovation center attached to our headquarters in Peachtree City, along with this manufacturing and distribution center, which was a $70 million investment.

Perhaps supply chain issues have been alleviated with manufacturing in the states. Here, in the 140,000-sq.-ft. distribution center, the inventory is aplenty with tankless units produced at the RAM Lakes facility.

Over the last four years, the company has invested $100 million to show its commitment to the North American market. “In 2020, amidst all of the chaos associated with the pandemic, our company chose to move forward and invest, break ground on the facility we are standing in today. I’m very proud of the hard work and dedication our team has put forth in this initiative, which is critical for our organization’s future growth and success,” said Windsor.

With a goal of 400 units manufactured per line, at the time of the Grand Opening celebration, one line was up and running with a projected three lines running by summer. In addition, the RAM Lakes facility has already employed more than a hundred of the new local top talent with a projected few hundred additional jobs to be added by the end of the year.

Exporting tankless. What a concept. How cool is that? “It is cool. We will be shipping them to Mexico and shipping them throughout Latin America. We have a fast-growing Latin American business. It’s fun to be able to make product here in the U.S. and ship to other parts of the world,” said Windsor.

Tanika Peoples, Senior Human Resources Generalist, talks about Rinnai’s core values at the new facility.

Moreover, with all of the supply chain issues and complexities, having manufacturing here in the states alleviated some of the hassle. “This will have a huge impact on our supply chain. No. 1, we will be making the product right here in closer to our customer, and No. 2, we don’t have to rely on containers and supplies coming out of China. We are purchasing many of the parts right here in the U.S. or we’re purchasing it from our company in Japan. That really simplifies the process; it gets the product much closer to us. It’s also building the competency for our team to be able to innovate going forward.”

** Rinnai is a $3.2 billion company that is seen as one of the leading gas appliance manufacturers in the world. Rinnai is a market leader in Japan, Asia, Australia, New Zealand, with businesses also in Italy and the UK. For more than 100 years, Rinnai has developed high-quality products to heat water and homes. However, within the last few years, the company has looked towards new expansion opportunities, including investing in new markets to sustain innovation as well as operationalizing manufacturing and production to meet need. The North American market was quickly identified as one of the greatest growth vehicles for the company. Rinnai entered North America in 1974 in Southern California, moved to LaGrange, Ga., and recently its headquarters in Peachtree City, Ga.

San Antonio — The seventh Emerging Water Technology Symposium returned as an in-person event for the first time in four years, bringing together industry, manufacturing, water utility and government leaders from around the world. A focus of this year’s event was on resources communities require to build safe and resilient plumbing systems as well as Read more

San Antonio — The seventh Emerging Water Technology Symposium returned as an in-person event for the first time in four years, bringing together industry, manufacturing, water utility and government leaders from around the world. A focus of this year’s event was on resources communities require to build safe and resilient plumbing systems as well as meet the growing list of challenges to America’s drinking water.

The esteemed panel on Effective Risk Management of Building Water Systems for Pathogen Control included (from l to r) Julius Ballanco, president, JB Engineering; Kurt Steenhoek, International Representative, UA; Janet Stout, Executive VP and Founder, Special Pathogen Laboratory; James Dipping, Director of Plumbing Engineering, Environmental Systems Design, Inc.; Christoph Lohr, VP of Strategic Initiatives, IAPMO; and Matt Freije, CEO, HC Info.

The May 10-11 event at the Westin Riverwalk, San Antonio was co-convened by the Alliance for Water Efficiency (AWE), the American Society of Plumbing Engineers (ASPE), the International Association of Plumbing and Mechanical Officials (IAPMO) and Plumbing Manufacturers International (PMI).

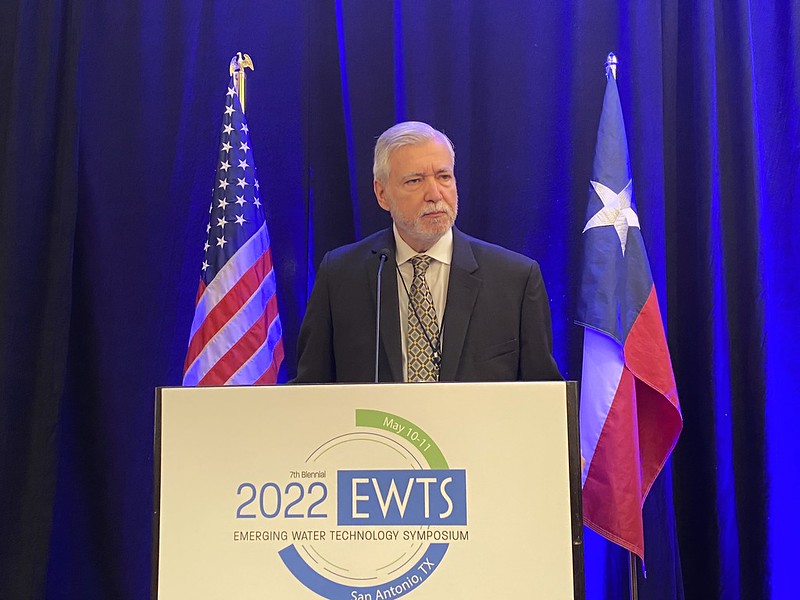

Pete DeMarco

“As an industry we have a number of high priority research needs that relate to water quality as well as water and energy efficiency,” IAPMO Executive Vice President of Advocacy and Research Pete DeMarco explained in discussing the importance of the symposium. “This year’s event brought together some of the brightest minds industry has to offer all focused on how we make our plumbing and mechanical systems safer and more resilient to meet the challenges ahead.”

In his opening remarks, DeMarco pointed to a number of accomplishments for which the EWTS has served as a springboard, including the development of the Green Plumbing and Mechanical Code Supplement (now the Water Efficiency and Sanitation Standard WE•Stand); ANSI/ASHRAE Standard 188-2018, Legionellosis: Risk Management for Building Water Systems; ASSE 12000 series on infection control and water quality, which is in IAPMO’s Uniform Plumbing Code (UPC®); and IAPMO’s Water Demand Calculator, whose second version was released in 2020.

“This symposium provides a much-needed platform for stakeholders across the industry to gather, discuss the latest research, and then discuss how we can take action,” he said. “It is a highly valuable event, and I look forward to seeing it continue to grow in the future.”

Kerry Stackpole

PMI CEO Kerry Stackpole spoke at the event and said the relationships between the organizations represented at EWTS had likely never been more important than they are now. He said that while the best and brightest among us devised medical solutions to the COVID-19 pandemic, the plumbing industry also played an important role.

“What’s also important is how our industry responded,” he said. “Our industry’s experience and our focus became touchless faucets, antimicrobial surfaces, water purification systems, all kinds of energy-efficient devices focused on safe and responsible plumbing. We all had a contribution to make and I think our industry stepped up.”

Stackpole said wildfires, flooding and drought that different regions of the United States are experiencing put those in the industry in a position to shape the future.

“Your active engagement here, in your communities back home, and in the marketplace of ideas, where we will have opportunities to share ideas with one another, will make all the difference,” he said. “You actually are able to turn the dial on this, and I think that’s really exciting.”

A day 2 panel saw (from l to r) Ed Osann, Senior Water Policy Analyst, NRDC; Dain Hansen, Executive Vice President, Government Relations, IAPMO; and Stephanie Salmon, Washington Representative, PMI, talk about the implications of the Infrastructure Investment and Jobs Act on Drinking Water and Wastewater.

This year’s keynote speakers were Robert Puente, president and CEO of the San Antonio Water System (SAWS), and Don Johnston, senior operations director, Indonesia, for Water.org.

Puente’s presentation looked at three ways in which SAWS, which serves 2 million customers over four counties, uses innovation to deliver water to its customers: advanced metering deployment, “smart” manhole covers, and conservation.

“It’s all about innovation,” he said. “And I think if you talk to our employees, although they will tell you that it’s their idea, we know that they got their idea from coming to events like this. Every good idea, you should expect it to be stolen, to be used by someone else, and you should be flattered by that. I think anything that you look at here started somewhere else, and we went to conferences in other cities and were able to bring back the ideas to SAWS to really get the innovation aspect in this.”

In delivering his keynote address remotely from Jakarta, Indonesia, Johnston spoke about the global water and sanitation crisis’s impact on low-income households — one in nine people lack access to safe water, one in three do not have access to a toilet — and some potential solutions. Working with financial institutions and water utilities, as well as sister company WaterEquity, Water.org helps bring affordable financing to people in need of water.

The Hub’s John Mesenbrink asks the hard-hitting questions during the symposium.

“In about 19 years of work on the ground, we’ve seen water and sanitation access reach more than 45 million people through more 10 million microloans disbursed to households with capital of $3.7 billion mobilized,” he said.

In his presentation, Phillip White, manager of plumbing and mechanical inspections for the city of Vancouver, British Columbia, shared how his city addressed the problem of insufficient sewer capacity when it came to capturing large amounts of rainfall through water reuse technologies. One development, the Oakridge Centre, utilized the IAPMO Water Demand Calculator and is expected to have the largest non-potable water system in North America.

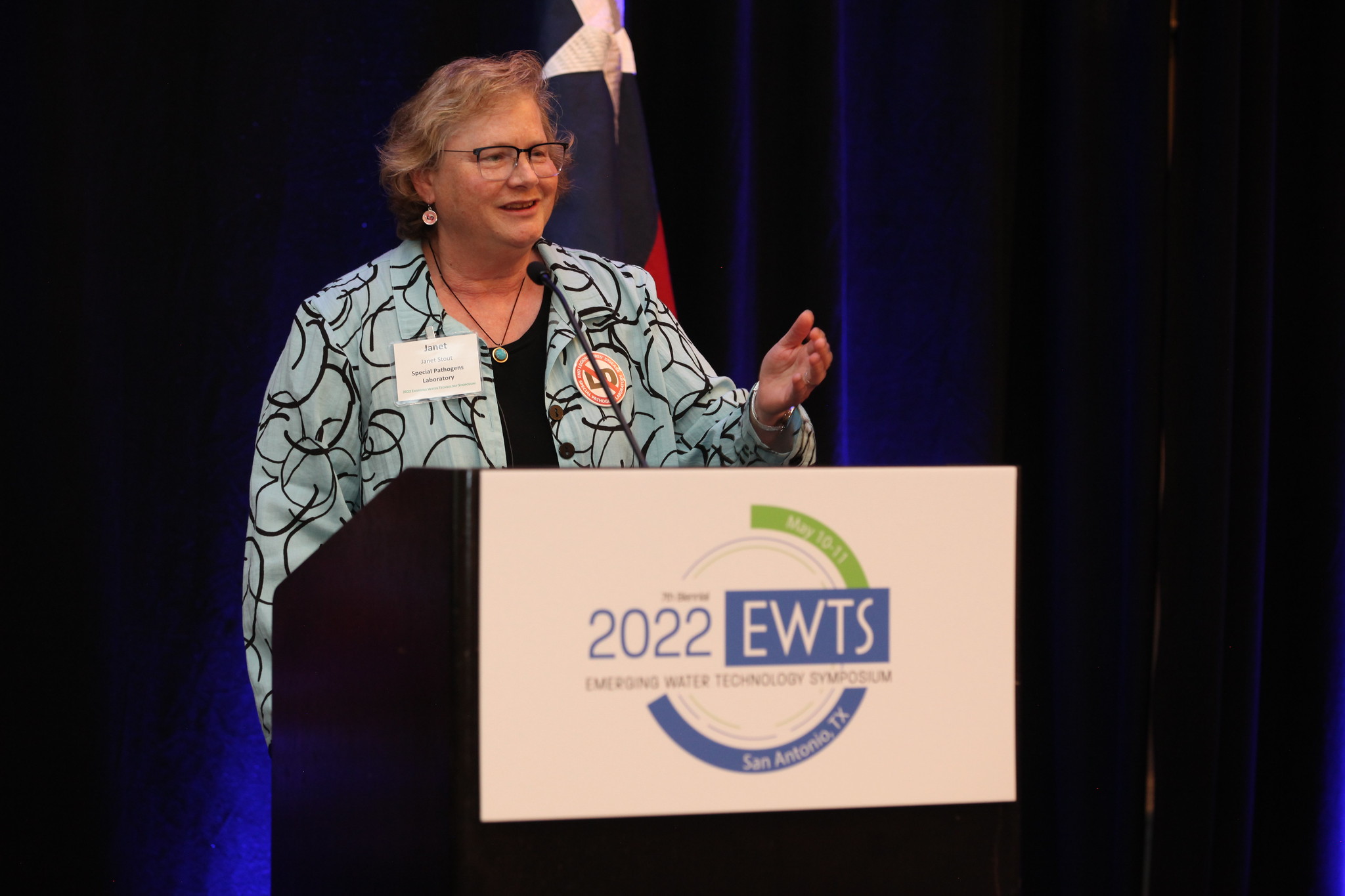

Janet Stout

Another speaker, Special Pathogens Laboratory Executive Vice President/Founder Dr. Janet Stout, looked at approaches and products for mitigating the risk of Legionellosis in point-of-use and point-of-entry building water systems. Improved water management requires knowledgeable Legionella prevention and water service providers, which can come from certification to ASSE/IAPMO/ANSI 12080 for Legionella Water Safety and Management Personnel.

IAPMO will provide sessions from the EWTS on-demand in the near future. To be notified when they are available, register at www.ewts.org/2022-ewts.

Flagship showroom in Fulton Market District highlights Sloan’s full suite of aesthetic, hygienic commercial restroom products. Chicago—On a dreary Tuesday morning in early May, Sloan sparkled by holding a ribbon-cutting ceremony to celebrate the opening of its flagship showroom and office space in the Fulton Market District. The flagship showroom highlights Sloan’s full suite of aesthetic Read more

Taking part in the ribbon cutting ceremony for the new space were Graham Allen and Kirk Allen, Sloan co-presidents and CEOs and fourth generation descendants of company founder William Elvis Sloan.

The Hub’s John Mesenbrink took part in some AR technology from the showroom.

Located on the building’s 10th floor, Sloan’s showroom space represents a return to the company’s origins, as Sloan was initially founded on nearby Jackson Boulevard prior to moving to its current Franklin Park headquarters in 1975. The new building features an office space and showroom, while Sloan’s manufacturing and corporate headquarters remains in Franklin Park.

The showroom features a wide range of Sloan products and innovations, including flushometers.

The showroom features a wide range of Sloan products and innovations, including sensor-activated faucets.

It was the most impressive gathering of young people interested in joining the trades that I have seen in quite some time. Iowa Skilled Trades (www.iowaskilledtrades.com), in conjunction with Home Builders Association of Des Moines (www.dsmhba.com) and the Skilled Trades Academy at Central Campus Des Moines Public Schools (https://centralcampus.dmschools.org/skilled-trades/), organized the very successful Iowa Build Read more

It was the most impressive gathering of young people interested in joining the trades that I have seen in quite some time. Iowa Skilled Trades (www.iowaskilledtrades.com), in conjunction with Home Builders Association of Des Moines (www.dsmhba.com) and the Skilled Trades Academy at Central Campus Des Moines Public Schools (https://centralcampus.dmschools.org/skilled-trades/), organized the very successful Iowa Build My Future event.

More than 5,000 students attended the Build My Future event held at the Iowa State Fairgrounds in Des Moines, Iowa.

Held at the Iowa State Fairgrounds, the third such event held live since its inception, Iowa Build My Future far surpassed any past events with more than 5,000 middle school, high school and other students—from more than 120 schools from across the state of Iowa—bussed in to take part of this career day, industry showcase and hands-on trades expo held April 13.

Students from across the state of Iowa participated in the hands-on Build My Future event, which included testing tools, working with ropes, roof building, excavating demos, and much more.

Brandon Patterson, architect of the Build My Future event in Iowa, is all smiles as the event went off without a hitch.

“The goal is to have the students get their hands on things they’ve never done before. Maybe they don’t have shop class, maybe they’ve never understood of any careers in manufacturing. We are letting them have a hands-on experience with these different careers,” says Brandon Patterson, workforce development, HBA of Greater Des Moines, the driving force behind the event.

Those different careers include plumbing, HVAC, electrical, carpentry, masonry, welding, and more. Housed inside and out, hands-on activities included soldering, roofing, welding and jobsite excavator demos, rope climbing with harnesses, and much, much more.

Students getting ready for the letter of intent signing.

During the show, there was a Letter of Intent signing, indicating that students intended to enter the trades after high school. “We are actually going to do a signing day for kids that are going into the skilled trades industry, most likely construction. We want to showcase these kids and show them what it’s all about,” says Patterson.

The letter also was co-signed by Iowa Governor, Kim Reynolds, who was in attendance for the Build My Future event. “I want to congratulate the students here today for taking the initiative to jump start your careers in apprenticeships that gives you an advantage; it gives you hands-on experience, a chance to earn while you learn, and it’s exciting,” said Reynolds.

The letter also was co-signed by Iowa Governor, Kim Reynolds, who was in attendance for the Build My Future event. “I want to congratulate the students here today for taking the initiative to jump start your careers in apprenticeships that gives you an advantage; it gives you hands-on experience, a chance to earn while you learn, and it’s exciting,” said Reynolds.

Reynolds continued, “I’m excited about the growth in Iowa’s registered apprenticeship programs. In 2021, we received 181 new programs in our state, the most ever in a single year and it puts Iowa as the national leader … we are going to continue to work with the kids, business, construction and the trades and we are going to transform the state of Iowa.”

Students were given plenty of swag from the event.

The letter signing was supported by RIDGID, Pfister, Iowa Skilled Trades and American Plumber Stories, and some key swag was given away at that time.

The Build My Future event left quite an impression on those attending, especially Mechanical Hub’s Eric Aune. “I wish I had something like this when I was in high school,” says Aune.

Prior to the Build My Future event, Mechanical hub was treated to a tour of the Skilled Trades Academy at the Central Campus in downtown Des Moines, Iowa. Tour guides Dan Knoup, executive officer, HBA of Greater Des Moines and Gary Scrutchfield, Lumberman’s Drywall & Roofing Supply, who are both active with the Skilled Trades Academy.

The Academy is open to 42 school districts and offers 89 various program courses from agriculture to electrical to plumbing to automotive to carpentry to marine biology. Yes, marine biology. High school students are transported there for a minimum of 90 minutes per visit to get them educationally on the right trade track.

The Hub’s Eric Aune interviews Mike Murphy, a former U.S. military serviceman, heads up the plumbing and mechanical department for the Skilled Trades Academy.

Central Campus complements and extends the programs of Central Iowa Schools, offering unique academic and career opportunities that direct, inspire, and motivate a diverse group of students.

Located at the heart of the model district for urban education, Central Campus offers hands on, real world work-based educational programs to a highly diverse community and surrounding areas. One of our greatest strengths is the friendships and networking of students from diverse backgrounds and communities. Des Moines Public Schools dedicates itself to excelling at unique and technologically advanced opportunities for all learners. Central Campus commits itself to providing equal access and prospects through rigorous academic and career training experiences for all.

Fun fact: the building was an assembly plant for Ford’s Model T.