We get our first in-depth look at the new Navien NFC We stopped at Navien’s booth at the AHR Expo to look under the hood of the new Navien NFC combi-boiler using Navien’s own firetube heat exchanger. Take a look at the video to see some details and specs, one thing that surprised me right Read more

Featured Articles

We get our first in-depth look at the new Navien NFC

We stopped at Navien’s booth at the AHR Expo to look under the hood of the new Navien NFC combi-boiler using Navien’s own firetube heat exchanger.

Take a look at the video to see some details and specs, one thing that surprised me right away was the included accessories. For contractors looking for high amounts of hot water production, a low head loss heat exchanger for easier piping on the hydronic side and additional features like remote connectivity it looks like the NFC is worth checking into. You can find more details and specifications on Navien’s website or here in our new product listings on Hydronics Hub.

All the bells & combi boiler whistles

The new Navien NFC combi boiler models come with a patented in-house designed and manufactured heat exchanger, Low Profile Burner for ease of service, advanced controls offering intuitive user navigation, a built-in DHW module (pump, flat plate heat exchanger, 3-way valve, mixing valve, water adjustment valve and auto water fill valve), common venting capability up to 8 units, cascading capability up to 16 units, and built-in hardware to connect up to 3 zone pumps without a need for additional external controllers.

It’s never a good thing when your building is known as “the leaky building.” That, however, was the unfortunate reputation of Windsor Over Peachtree, a 22-story, 265-unit condominium building in Atlanta. The vapor barrier on the 53-year-old building’s existing steel and copper piping had deteriorated, and the condensation that was forming on the pipes was Read more

It’s never a good thing when your building is known as “the leaky building.”

That, however, was the unfortunate reputation of Windsor Over Peachtree, a 22-story, 265-unit condominium building in Atlanta. The vapor barrier on the 53-year-old building’s existing steel and copper piping had deteriorated, and the condensation that was forming on the pipes was causing them to break down from the outside in. The combination of leaks caused by age and damage caused by dripping condensate was proving to be a regular and ongoing challenge in the building, and the need for an upgrade was apparent.

Windsor Over Peachtree is a 265-unit condominium building built in 1965.

“The management and maintenance staff had been chasing leaks for years,” said Jeff Long, Southeast District Product Manager, Commercial Group, Ferguson, the largest wholesale distributor of residential and commercial plumbing supplies and pipe, valves, and fittings in the U.S. “We had several discussions with them about changing out the piping.”

As might be expected in a half-century-old building, the challenges with the HVAC system ran deeper than just the piping. Foremost among the other issues was that the old two-pipe fan-coil system was struggling to keep up with the cooling demand during Atlanta’s hot summers. So when the money for an HVAC system upgrade was allotted, it was decided that a new system of water-source heat pumps—sized to handle the building’s 500- to 600-ton cooling demand—would replace the old fan-coil system that had been sized for a 300-ton demand.

‘Not Your Typical Plastic’

For Joe Escher, Vice President of E. Escher Inc. Mechanical Contractors, Roswell, GA, the project represented his firm’s first opportunity to perform a large-scale installation of Aquatherm PP-R piping.

At this project, Aquatherm Blue Pipe® replaced an old and leaky system composed of steel and copper pipe.

“This wasn’t your typical job where an engineer draws up a spec and everybody follows it,” Escher said. “We worked closely with the engineer and the building owner in a collaborative effort to determine the best equipment and the best piping system.”

Escher was on board with the conversations between the building owner and engineering firm about using Aquatherm, but he also wanted to see for himself the benefits of PP-R pipe.

At Windsor Over Peachtree, the piping had to run through 8-in. thick concrete floors with 10-in. square blockouts.

“Everyone has an ‘a-ha!’ moment when it comes to choosing PP-R pipe, and before it was determined that we were going with Aquatherm we visited Joe at his shop,” Long relates. “We put together some sections of 2 ½-in. pipe, and Joe tried to drive a nail through them with a hammer. I remember him reporting back and saying, ‘This is not your typical plastic.’”

Escher pointed out that he also researched the pipe using more sophisticated methods, but he does not discount the value of the hammer-and-nail test.

“Aquatherm is a plastic, but don’t even consider equating it to something like PVC or CPVC,” he said. “If you look at a cross-section of it you can see that it doesn’t even compare to those pipes. It’s in a class of its own.”

Ultimately, the decision to use Aquatherm pipe to serve the new heat pump system was an easy one.

“The building management didn’t want to use any flame or welding in an occupied building, and the project’s engineer didn’t like the idea of having a copper-press system behind the walls,” Long explained. “That gave us the opportunity to discuss Aquatherm pipe, and it turned out to be the perfect solution for this retrofit.”

In with the New

At the Windsor Over Peachtree project, more than 6,000 ft of Aquatherm Blue Pipe® SDR-11 ranging in size from ½ in. to 4 in. was installed, along with new Raypak boilers, Evapco cooling towers, Bell & Gossett pumps, and JCI-branded WaterFurnace water-source heat pumps.

Aquatherm pipe was able to be heat fused and installed in tight quarters without welding or open flame, which was extremely important in an occupied building.

Installation was made challenging because the floors were concrete slabs 8-in. thick, with blockouts approximately 10-in. square in identical locations from the fourth through the 20th floors. The existing risers went straight up through the blockouts without any offsets.

It was determined early on that the ability to fabricate Aquatherm offsite and transport the fabricated spools to the jobsite ready to install was going to be an important component of this project. Escher personally drew up the 16 sets of risers needed for the project and they were fabricated at Ferguson’s facility in Fulton, MS. The risers consisted of 1¼-in. through 4-in. pipe, with ¾-in. runouts.

“The fabrication was right on the money,” Escher said. “We had more than 4,000 joints in this system, and we had five leaks. On a typical solder job we’d expect around three percent. So we were very impressed with the extremely minimal leakage of the Aquatherm.”

Also impressive was the time savings of the off-site fabrication. Escher estimated it saved about four to five days per riser.

“It really worked out well to have Ferguson’s people fabbing and our people installing,” he said. “Ferguson had all the fabrication equipment and lower labor rates than what we pay our pipefitters. So when you combine the lower labor rate and the better equipped shop minus the cost of freight, they were very competitive.”

In addition, he said, having the fabrication done offsite allowed his company to use its shop personnel in the field.

“The result is that without adding any costs we were able to dramatically reduce the time to complete the project,” Escher said. “This was very important because whenever we took a riser out of service we had about 20 condos that did not have heating or cooling until the new Aquatherm piping and WSHPs were installed and operational.”

Escher noted that the light weight of PP-R pipe provided an added benefit.

“We had to take all the piping up in elevators, in nine-foot maximum sections, and even the four-inch pipe could easily be carried and handled by one person,” he said.

The piping’s virtually leak-free performance impressed the installing contractor.

The installation and onsite heat fusions were performed by Escher’s team using McElroy irons and McElroy Spider® 125 with Chain Clamping, which allowed them to perform heat fusions in the tight quarters of the blockouts.

“The Chain Spider allowed Escher’s team to get up against the wall like they needed to,” Long noted.

Unistrut Metal Framing Systems and Walraven hangers were used to position the new piping spools in the existing blockouts.

“It was very simple and it worked perfectly,” Escher said.

Benefits in Occupied Buildings

Other piping options such as steel and copper were initially considered for Windsor Over Peachtree, but the engineer had misgivings about those options in an occupied building.

“We were looking for a way to avoid welding or brazing pipe in an occupied building,” said Tim North, P.E., LEED AP, principal, Johnson, Spellman & Associates Inc. “The fact that no hot work permit was required was an important factor for us in selecting Aquatherm. It was the best solution in an occupied building.”

In addition, Escher noted that unlike welding, Aquatherm’s heat fusion process gives off no fumes or VOCs. That added to its attractiveness for Windsor Over Peachtree.

Investigation Leads to Appreciation

Although this was Escher’s first opportunity to use Aquatherm PP-R piping on a large-scale project, he and his team already feel like old hands with it. And he offered some advice to other contractors and engineers who are considering Aquatherm for a piping project.

“Do what we did,” Escher said. “Investigate it, look at other projects that have used it and talk to contractors who have installed it. You’ll find the same things I did: it’s tough, it’s lightweight, leaks are almost non-existent, and it has a built-in insulation value that may allow you to reduce the thickness of the insulation. In addition, the lack of flame and welding makes it very well-suited for retrofit projects.”

Offsite fabrication done by Ferguson helped speed this project along, as ready-to-install risers were shipped directly to the jobsite.

The fine aesthetic value of Aquatherm compared to steel also shouldn’t be overlooked, Escher added. “This system is running at 45°F to 90°F and didn’t require insulation,” he said. “However, we have some runs that are exposed in corridors, and if we had used steel pipe we would have had to paint it. Aquatherm, on the other hand, has an attractive exterior.”

A final bonus for Escher and his people on this project is something that can be all too rare in the construction industry: appreciation. The building went from a two-pipe system where the main HVAC system was either in heating or cooling mode to a system that can provide concurrent heating and cooling based on individual occupants’ preferences.

“Many tenants have been blown away by how comfortable it now is in their spaces,” Escher said. “We got tons and tons of compliments. So it was a very good project for us. The condo owners are happy, the building management is happy, and it worked out well for us. We’re very pleased and proud of this job.”

“I’m glad somebody out there cares about me,” said the eight-year-old child, now beaming with joy because he had just received a new pair of shoes for the holidays. For Bob Carpenter, hearing these words tugged at the heartstrings and made the effort so well worth it. You see, Carpenter’s full-time job is Outreach and Read more

Bob Carpenter, right, diligently runs the shoe drive.

“I’m glad somebody out there cares about me,” said the eight-year-old child, now beaming with joy because he had just received a new pair of shoes for the holidays. For Bob Carpenter, hearing these words tugged at the heartstrings and made the effort so well worth it. You see, Carpenter’s full-time job is Outreach and Education Manager, U.S., for Reliance Worldwide Corporation, yet spends most of his remaining time dedicated to his second full-time job, as CEO of the United Craftsman Children’s Shoe Drive (UCCSD), Inc., a non-profit organization that puts shoes—and now socks—on the feet of children from Children’s Homes and Foster Care.

The idea started back in 2005 when Tracy Newsome collected donations from fellow craftsman to “put shoes on those babies’ feet.” In 2009, Newsome was tragically killed in a car accident returning home from a job running cast iron for Art Plumbing at the Atlanta Hartsfield Jackson International Airport.

At his memorial service, Newsome’s widow asked Carpenter if he could help out and take over the shoe drive. He accepted, and what started with providing for 27 kids in the Atlanta area has turned into helping hundreds of kids every year.

It’s all about the kids.

In 2012, what was originally the TAN Shoe Drive becomes the United Craftsmen Children’s Shoe Drive, Inc., a 501 (C) 3, a federally recognized, non-profit charity incorporated in the State of Georgia. “The UCCSD is completely volunteer with no one receiving any compensation or travel reimbursements,” emphasizes Carpenter.

In 2014, UCCSD Inc. expanded into Birmingham, Ala. from the help of Wayne Brown, a retired plumber—a man whom Carpenter had never met. Brown helped set up a charity fishing tournament that started with six boats initially and turned into 27 (with the help of an anonymous contractor donor).

In 2017, in addition to the Atlanta and Birmingham, Ala. areas, UCCSD expanded with events in Daytona, Fla. and Tulsa, Okla. This year they will be branching into the Tampa, Fla. area, as well. In January 2017, James Reeves, Jr., a veteran of the U.S. Navy, and southeast regional sales manager for the ACCOR Technology, was named president of the UCCSD, and is now present at all of the fundraising and Shoe Drive events.

In 2017, in addition to the Atlanta and Birmingham, Ala. areas, UCCSD expanded with events in Daytona, Fla. and Tulsa, Okla. This year they will be branching into the Tampa, Fla. area, as well. In January 2017, James Reeves, Jr., a veteran of the U.S. Navy, and southeast regional sales manager for the ACCOR Technology, was named president of the UCCSD, and is now present at all of the fundraising and Shoe Drive events.

With the assistance from Shoe Carnival, which offers a 30% discount on all shoes purchased, most of the donations come from contractors, skilled craftsmen, and skilled trades organizations. Also, “Reliance Worldwide has been very supportive of my efforts,” says Carpenter.

The Shoe Drive’s mission is admirable—to let children who live in children’s homes know that the skilled craftsmen care about them by affording them the opportunity to pick out a new shoes, socks and enjoy a lunch with other children living in similar circumstances. For more information on the Shoe Drive, visit them online at www.unitedcraftsmenchildrensshoedriveinc.org.

Water Sanitation

If that wasn’t enough, Carpenter sits on the PHCC Georgia Board and the Georgia State Inspectors Association, and also recently played a major role with the International Water, Sanitation and Hygiene (IWSH) Foundation’s 2018 Community Plumbing Challenge (CPC) and the Navajo Water Project in Thoreau, New Mexico, an initiative to help ensure that every American has clean, running water forever.

A range of bathroom and kitchen renovations were carried out, including the installation of new basins, taps, toilets, water tanks, water pumps, and hot- and cold-water pipework. These renovations and repairs are required in order for these homes to be connected to water supply systems. Meanwhile, efforts outdoors will address the installation of, and connection to, new wastewater systems. In some instances where some residents of homes that grew up without any running water or indoor plumbing, through the help of some industry manufacturers and 60 plumbers, “We were able to equip 10 houses with water and proper sewage disposal. In one home, we witnessed a woman cry the moment we turned the water on,” says Carpenter.

A range of bathroom and kitchen renovations were carried out, including the installation of new basins, taps, toilets, water tanks, water pumps, and hot- and cold-water pipework. These renovations and repairs are required in order for these homes to be connected to water supply systems. Meanwhile, efforts outdoors will address the installation of, and connection to, new wastewater systems. In some instances where some residents of homes that grew up without any running water or indoor plumbing, through the help of some industry manufacturers and 60 plumbers, “We were able to equip 10 houses with water and proper sewage disposal. In one home, we witnessed a woman cry the moment we turned the water on,” says Carpenter.

Finally, Carpenter was asked to visit the Navajo Indian Reservation in Pinon, Ariz. to talk plumbing and teach some real-life skills to some 85 kids. Where others have declined the invitation due to the off-the-beaten-path location of the reservation, Carpenter does what he always does, and agreed to lend his time and expertise. “Everyone deserves a chance,” says Carpenter.

Judging from his work with the Shoe Drive and his efforts in the plumbing industry, you believe him at his word, and you can’t help but root for this guy.

An occupied 12-story commercial building–plus the need to replace nearly all the pipe and fittings—could only call for one thing. Viega ProPress. A crew from Green Team Services Corporation was brought in to update a large commercial office building in downtown Miami that was full of old galvanized pipe. James Terry, founder and president of Read more

An occupied 12-story commercial building–plus the need to replace nearly all the pipe and fittings—could only call for one thing. Viega ProPress.

A crew from Green Team Services Corporation was brought in to update a large commercial office building in downtown Miami that was full of old galvanized pipe. James Terry, founder and president of Green Team, said they replaced “every single piece of water pipe in that building,” which includes a restaurant on the first floor.

Built in 1970, much of the mechanical equipment in the 140,000-sq.-ft. building needed an upgrade. The company that had recently purchased the building decided to put in new chillers and replace the domestic water system. But because the building was fully occupied, it made things trickier, meaning Viega was even more attractive as the solution.

Work took about a month and a half in total. There were multiple phases to the job – changing over galvanized pipe to copper and installing new ball valves on each floor. There were multiple low- and high-pressure mains into the building, plus the team put in a new pump skid.

The first phase included running all new 4″ piping in the mechanical room which was in the basement. Terry said his crew spent about three weeks installing new water mains and then came back for a large overnight shutdown.

The first phase included running all new 4″ piping in the mechanical room which was in the basement. Terry said his crew spent about three weeks installing new water mains and then came back for a large overnight shutdown.

“We had 11 plumbers for 12 hours, overnight, from 9 p.m. to 9 a.m. It was a real marathon!” he said. “It would have been impossible without ProPress. The planning and the logistics that go along with an overnight project like this are huge, and it’s much more efficient to do with Viega.

“There are no surprises with ProPress. You know you have everything you need. I would never have done this job without being able to press. You’re talking over 100 joints in one night. You couldn’t solder that or do it any other way.”

Terry said using ProPress, particularly on the overnight portion of the job, kept the budget down for the client by having labor as low as possible. It also helped the team get the job done efficiently while having as little of an impact on the building’s occupants as possible.

Terry said using ProPress, particularly on the overnight portion of the job, kept the budget down for the client by having labor as low as possible. It also helped the team get the job done efficiently while having as little of an impact on the building’s occupants as possible.

Green Team bid the job with ProPress specified. Terry said they’ve been using Viega

for the past decade and can’t imagine using another method. “It’s the simplest form. I wouldn’t make a domestic water repair that was copper [without ProPress],” he said. “We have so much experience using Viega, and we’re so comfortable with it. The ease of use and the installation process is great – you just go get a couple of boxes of fittings, the press gun, and you’re ready to go.”

Green Team has multiple bins of “emergency” Viega fittings in the most popular types and sizes in its warehouse so that if they have an unexpected shutdown in the middle of the night, they don’t have to depend on their suppliers when it’s 3 a.m. However, Terry noted that Lehman Pipe in Miami has twice been kind enough to open in the middle of the night for the Green Team when they needed some unique parts that weren’t already on hand.

“We work on all kinds of buildings – offices, healthcare, education and hospitality type – and none of them want to wait to have their water on,” Terry said. “For me, Viega means you can get to the next job quicker because you’re getting the job done right the first time, and you know there aren’t going to be any issues.”

Click here to see this article in the November 2018 issue of Viega Voice.

The Design-Build Institute of America (DBIA) has announced the winners of its 2018 National Design-Build Project/Team Awards competition. The program promotes exceptional diversity in project size, sector, and geography while celebrating the innovative and collaborative teams who produce projects that inspire. This year’s winners, consisting of 29 projects across sectors including aviation, civic buildings, transportation Read more

The Design-Build Institute of America (DBIA) has announced the winners of its 2018 National Design-Build Project/Team Awards competition.

The program promotes exceptional diversity in project size, sector, and geography while celebrating the innovative and collaborative teams who produce projects that inspire. This year’s winners, consisting of 29 projects across sectors including aviation, civic buildings, transportation, and water/wastewater, were recognized at DBIA’s Design-Build Conference and Expo on Nov. 8 in New Orleans.

Within the water/wastewater category, two Brown and Caldwell-involved projects received accolades:

• National Excellence Award – RM Clayton Water Reclamation Center Headworks (City of Atlanta Department of Watershed Management)

RM Clayton Water Reclamation Center Headworks (City of Atlanta Department of Watershed Management)

• National Merit Award – Bush Beans Process Water Reclamation Facility (Bush Brothers & Company)

Bush Beans Process Water Reclamation Facility (Bush Brothers & Company) Photo Credit: Antonio Valdivia

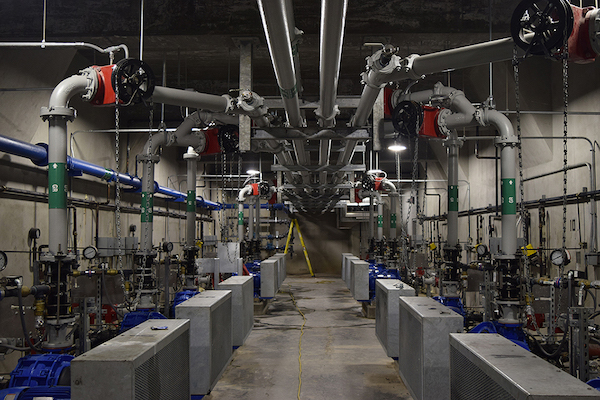

The headworks facility at the RM Clayton Water Reclamation Center, Atlanta’s largest wastewater facility, provides a critical function as the first line of defense in wastewater treatment as it collects and treats flows from a combined stormwater and sanitary sewer system. The varying sources of influent results in wide flow rate fluctuations containing large quantities of difficult to remove grit. To mitigate the harmful effects of grit accumulation and facility wear, the city selected a design-build team of Western Summit/Anatek, Inc./Brown and Caldwell to implement immediate and long-term solutions and provide reliability.

RM Clayton Water Reclamation Center Headworks (City of Atlanta Department of Watershed Management)

The $53.5 million project included headworks upgrades, replacement of coarse screening and grit removal systems with a 12-cell, multi-tray HeadCell grit extraction structure, and installation of new influent monitoring equipment to integrate with the digital control system at the 240 million gallons per day (MGD) facility. Complex excavation, drilling, and blasting of 35-foot sloped and 40-foot vertical areas within the facility was included to make room for the new HeadCell facility.

Addressing the city’s need to maintain operations, a temporary retrofit of the existing grit removal system was implemented to provide immediate grit relief and downstream process protection.

By leveraging the collaboration inherent in the design-build delivery method, the overall schedule was reduced by 18 months compared to a traditional design-bid-build delivery method.

Located rurally in the Great Smoky Mountains approximately 40 miles from Knoxville, Tennessee, is Bush Brothers & Company’s (Bush’s Best Baked Beans) new $55 million Process Water Reclamation Facility (PWRF). Led by a design-build joint venture of Brown and Caldwell and Haskell, the new 2.1 MGD facility treats production process water to a high effluent quality for agricultural irrigation along with reuse within the PWRF and non-food contact production applications at the Bush Brothers & Company main production plant.

Bush Beans Process Water Reclamation Facility (Bush Brothers & Company) Photo credit: Antonio Valdivia

The design-build team collaborated with Bush Brothers & Company to deliver a cost-effective, aesthetically pleasing solution that complements, rather than intrudes on the landscape surrounding the Great Smoky Mountains. This socially responsible project was delivered $13 million below budget.

“Our warmest congratulations go to the city of Atlanta and Bush Brothers & Company for recognition and celebration of their visionary leadership and innovation,” said Brown and Caldwell Senior Vice President and Integrated Project Delivery Director Shawn Sock. “We are very honored to have been trusted with the opportunity to contribute to the success of these projects and are so grateful for the collaboration, dedication, and professionalism of the project teams we were privileged to join.”