Working in the trades business can be challenging. You need to spend time learning and perfecting your skill set, but it is also important that you focus on doing as much as you can to stand out and get ahead of the competition. Starting out as a new plumber can be pretty daunting, and there Read more

Industry Blogs

Working in the trades business can be challenging. You need to spend time learning and perfecting your skill set, but it is also important that you focus on doing as much as you can to stand out and get ahead of the competition. Starting out as a new plumber can be pretty daunting, and there are a lot of ideas and processes that you should be thinking about moving forward.

Make sure you focus on doing as much as possible to improve your prospects, and to give yourself the greatest chances of success. There are a lot of things that you need to make the most of right now, and this is something that you have to keep in mind as much as possible. Try to work on the best ways of being able to do this. Here are some of the key examples.

Promote Yourself Effectively

Promoting yourself effectively is one of the best things that you need to do as a budding new plumber, and this is something to work on right now. Try to make sure you come up with some of the best ideas you can use to get your name out there and achieve success. You have to improve and boost your reputation, and make sure you do as much as possible to achieve this. Focusing on social media marketing is one of the most effective ways of being able to achieve this right now, and there is a lot to consider here moving forward. Do your best to focus on being able to achieve this process, and there are a lot of things that you need to get your name out there and really get people excited about the business and you as a professional

Develop a Customer Base

Developing a customer base is one of the key things that you need to improve upon as a budding plumber, and this is the area where you are able to achieve success moving forward. There are a lot of things that play a part in this, and a lot of it is about developing a strong reputation and being able to improve the way you do things as a plumber. You have to provide service of the highest quality, as well as present yourself in a professional and reliable way, and this is one of the key things that you can do to boost reputation and help secure a strong customer base for regular business.

Always do Everything By the Book

There can be a tendency to cut corners when you are first starting out because you want to rush through things incredibly quickly. However, this is something that you should be looking to avoid as much as possible. You need to do what you can to be able to ensure you do things by the book, and this is a great way of being able to make the most of this right now. This means making sure you have the right tools and that you fit and repair things in the correct way. It means remembering to wear a mask and use hand sanitizer. In fact, you could even combine this step with the marketing step by heading to 4 All Promos and stocking up on some branded hand sanitizer. Ensure you do everything in the right way, and that you always place priority on being able to be honest and forthright; this can make all the difference to how you are perceived.

There are plenty of steps you can take that are going to allow you to improve upon this, and there are so many things that play a role in this process moving forward. Try to focus on doing what you can to improve your prospects this year and try to stand out as a new and reliable plumber. Being able to make use of these factors is definitely something that you should be looking to make the most of right now, and there are a lot of things that can help you significantly with this as a working professional.

For more info, check out this blog on some of the best plumbing tools.

Unemployment rates in the trade industry remain low. While that’s good for workers and the economy, it makes finding quality new talent a challenge and means employee retention is more important than ever. An old saying teaches that “Employees don’t leave jobs; they leave employers.” A healthy work environment doesn’t just produce happy employees. It Read more

Unemployment rates in the trade industry remain low. While that’s good for workers and the economy, it makes finding quality new talent a challenge and means employee retention is more important than ever. An old saying teaches that “Employees don’t leave jobs; they leave employers.” A healthy work environment doesn’t just produce happy employees. It makes happy customers, too! At Nebrasky Plumbing, Heating & Cooling, we’re proud to have built a work culture that extends to our work ethic. It’s a model from which employees, management, and customers all benefit.

Our approach began, ironically enough, when unemployment was at an all-time high – early in the COVID-19 pandemic. Then, finding new team members was a challenge for a variety of reasons, so owner Paul Nebrasky did what so many business owners found they needed to do to keep the lights on during lockdown. He adapted.

Nebrasky began an initiative to retain good workers by hiring an internal brand ambassador who, in addition to representing the company, could consistently engage with employees. The position needed to be filled by a leader and natural communicator who could seamlessly integrate into our organization to facilitate new ideas, implement trainings, and make employees recognize that they are vital to our mission and our clientele.

It worked. Now, what began as adaptation to a crisis remains as an example of how employee moral goes hand in hand with customer satisfaction.

Employees who know they are valued by their employer are more motivated, attentive, and detail oriented than those who simply clock in to collect paychecks. Out team’s newfound sense of camaraderie amounts to a renewed sense of purpose, a responsibility to perform quality work not only for our customers but for the benefit of our collective – and for personal satisfaction, as well.

Company culture is part of an organization’s brand and says more than an advertisement can – and with fewer words. While our brand ambassador initiative began with an internal focus on our employees, it has had the effect of creating a multitude of ambassadors. When a motivated Nebrasky technician introduces themself at your door, they are introducing you to our team and our values. The face of a contented employee is the face of our company, and a job well done is our calling card!

Paul has grown Nebrasky Plumbing, Heating & Cooling from a single plumbing truck to a multi-disciplinary plumbing and HVAC company with nearly 50 employees. When he took over his father’s business, he was a 23-year-old operating out of his house. That was 1988. Today, the company offers plumbing installation, service, and repair; new construction plumbing; heating; air conditioning; and home energy assessments to a nine-county market area – all from its office and warehouse facility in Monroe, NY.

Paul has grown Nebrasky Plumbing, Heating & Cooling from a single plumbing truck to a multi-disciplinary plumbing and HVAC company with nearly 50 employees. When he took over his father’s business, he was a 23-year-old operating out of his house. That was 1988. Today, the company offers plumbing installation, service, and repair; new construction plumbing; heating; air conditioning; and home energy assessments to a nine-county market area – all from its office and warehouse facility in Monroe, NY.

By: Chris Holbert, CEO of SecuraTrac Being a plumber is one of the most dangerous jobs in America. According to the Bureau of Labor Statistics, plumbers have one of the highest rates of injuries among all occupations. Often times plumbers are prone to slips and falls from high heights, working in confined spaces, and more Read more

By: Chris Holbert, CEO of SecuraTrac

Being a plumber is one of the most dangerous jobs in America. According to the Bureau of Labor Statistics, plumbers have one of the highest rates of injuries among all occupations. Often times plumbers are prone to slips and falls from high heights, working in confined spaces, and more. While plumbers have cell phones on them on the job, as well as having and wearing protective/preventative gear or equipment, it’s not necessarily the most efficient way to keep them safe or provide them tools to react in an emergency.

Depending on the job and what scenario they find themselves in, plumbers may not always have the ability to call 911 in an emergency. Or if they fall or a struck by an object, plumbers may be unconscious. This common scenario makes it impossible for the workers to use a cell phone and reach for help.

According to the Pew Research Center, approximately 95 percent of Americans now own a cell phone of some type, and more than one-third own a smartphone. Although these devices may provide many conveniences to users, in emergency situations their use is limited. Cellular devices require the user to still be conscious, or within range of the phone to call for help, making the device un-reliable for plumbers and not the most plausible option for ensuring workers stay safe.

But there’s a better solution to providing emergency communication for workers that can be easily carried or worn. The specific devices we are talking about is mPERS devices, which can automatically report an incident to emergency services so workers can receive help as soon as possible. mPERS devices, which have been used by seniors for years, are essentially a help button that can be pressed to alert emergency services that a worker needs help. In recent years, these devices have become even more beneficial outside of the senior space because they no longer require a base station device to place calls, which limited their range of use.

mPERS devices are small, portable, and lightweight. They use up-to-date location technology, and some even offer built-in fall advisory capabilities. These devices can detect horizontal and vertical movement and can initiate a call for help to emergency services without the need to even press a button. This is perfect in situations where plumbers may be unresponsive because of an accident or medical emergency, eliminating the need to call for help themselves entirely. The cloud-based technologies found in mPERS devices make it possible for Central Stations to pick up and response to the need for help as soon as possible. If a worker falls on the job, the device can report it via a text message or red flag in a software system.

The devices can also last much longer on one charge than a normal cell phone, making this another benefit of a mPERS device being used by plumbers. By having less functions, no screen, apps, or texting ability to drain battery, you aren’t constantly on them doing something. They can be turned off, but many also come with a “sleep” mode, where once the SOS button is pressed, the exact location information of the worker is sent to a central reporting station where an emergency call can be placed. There are mPERS devices on the market that can last up to 30 days on a single charge.

The use of mPERS devices can also make it easier to keep track of the number of incidences that occur, where they occur, and the type of accident that occurs. This is valuable information that can help implement newer safety tactics to avoid a repeat accident, for both workers and employers.

But not just any mPERS device can satisfy all the needs of all plumbers that will be utilizing this device. Several things should be considered before selecting a device. One of the most important considerations is looking into mPERS devices that are capable of 5G technology. By the end of this year, all major cell phone networks will fully transition to 5G technology, making out-of-date devices that can only handle 3G or 4G useless. Another consideration is the ability to upgrade an mPERS device down the line if it becomes necessary with new data networks and technologies evolving every day.

Whether it’s a pendant, clipped to the pocket or belt, etc. picking a wearable device (mPERS device) that makes the most sense for plumbers’ specific needs is an important part of taking advantage of all of the safety benefits that can potentially help save loves and improve the health of plumbers.

Personal Protective Equipment (PPE) has moved beyond heat insulated gloves, hard hats, eye protection, etc. While these are all vital pieces of equipment for plumbers to use, they can’t prevent and protect against everything. mPERS devices are another great addition to plumber PPE that doesn’t take up space, is easy to use, and can even work on its own without a user doing anything. Plumbers, and companies, should seriously consider and look into employing these devices as a standard across their practice. Instead of being stranded or calling out for help, a worker can receive connection to emergency services within seconds and in turn, prevent a bad situation from becoming worse by just the push of a button.

Chris Holbert is the CEO of SecuraTrac. SecuraTrac® develops, markets, and sells a suite of mobile safety solutions focused on improving senior and employee health and safety through mobile, location-based technology and state-of-the-art, cloud-based platforms. For more information please visit: www.securatrac.com.

Chris Holbert is the CEO of SecuraTrac. SecuraTrac® develops, markets, and sells a suite of mobile safety solutions focused on improving senior and employee health and safety through mobile, location-based technology and state-of-the-art, cloud-based platforms. For more information please visit: www.securatrac.com.

As the demand for more energy-conscious water heating solutions continues to grow, the industry is seeing an increase in the popularity of heat pump water heaters – a product rated three times more efficient than a standard tank electric water heater. This trend has allowed manufacturers to focus on creating more energy-efficient technology with the Read more

As the demand for more energy-conscious water heating solutions continues to grow, the industry is seeing an increase in the popularity of heat pump water heaters – a product rated three times more efficient than a standard tank electric water heater. This trend has allowed manufacturers to focus on creating more energy-efficient technology with the homeowner and professional in mind. Driven by factors including government regulations, customer demands and the desire for smart technology, A. O. Smith strives to be a key resource for customers by providing insights and solutions to help move the industry forward.

Regulations and rebates

To support decarbonization and electrification efforts, local, state and national governing bodies have set, or are currently vetting, regulatory standards that have already elevated the demand for heat pump products. Tax credits and rebates are also helping to drive the adoption of heat pump water heaters in new construction and existing homes by giving consumers more reasons to switch from traditional electric or gas water heaters to heat pump water heaters.

The Inflation Reduction Act, which was passed in mid-2022, will have a direct impact on the water heating industry. It includes increases in tax credits for homeowners and homebuilders, which will help lessen the financial investment that often comes with purchasing a heat pump water heater and select high-efficiency gas water heaters.

Starting in 2023, the tax credit for heat pump water heaters will be 30% of the total cost to purchase and install the unit up to a cap of $2,000. This variable tax credit will offer significantly higher upfront savings to homeowners in 2023, especially when combined with local utility rebates, which can run as high as $1,000 in some states.

To make it easier for customers purchasing energy efficient water heaters to find local rebates and tax credits, A. O. Smith also offers a ZIP code-enabled rebate finder powered by EcoRebates. The tool helps streamline the process by allowing customers to enter their location to see current rebates available for a wide selection of high-efficiency products.

Professional perks

Along with the desire for increased cost-savings comes the need for an improved installation and service experience for the professional. A. O. Smith recently launched the Voltex AL (anti-leak) heat pump water heater, a first-of-its-kind water heating solution with updated water connections, smart connectivity and integrated leak detection.

Installation flexibility was a priority when designing the Voltex AL model, providing professionals with a universal replacement option. Incorporating a zero-clearance design for the sides and back, as well as top and front water connections, this product is an ideal choice for a variety of new and retrofit applications. The Voltex AL heat pump water heater also operates at 45 dBA, making it the quietest model currently on the market.

The ENERGY STAR® certified Voltex AL® product features an incredibly high Uniform Energy Factor (UEF) of 4.02 with the 66-gallon unit and 3.8 with the 50-gallon. It’s also available in an 80-gallon model.

Smart technology

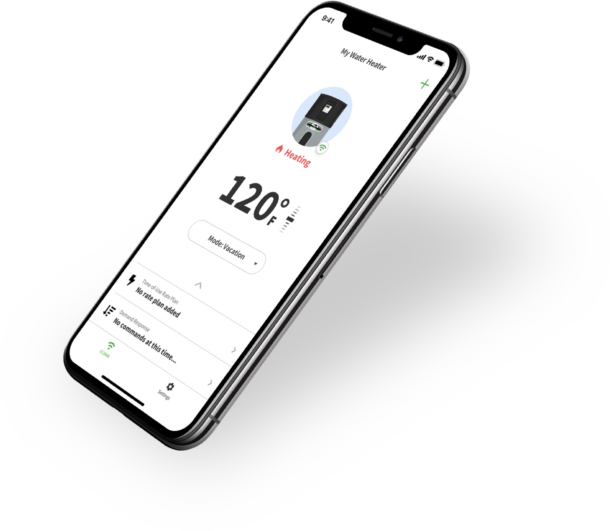

Another key driving factor in the development of heat pump water heating technology is the adoption and integration of smart features. As technology evolves, more homeowners are interested in controlling their appliances remotely using their smartphones.

With the new Voltex AL heat pump water heater, the integrated iCOMM™ connectivity platform supports features like anti-leak technology through the use of integrated leak detection and a smart anode. Using the A. O. Smith mobile app, professionals and homeowners can remotely monitor and adjust the water heater to improve performance and increase savings. For added peace of mind, the smart sensor provides notifications through the notification-enabled mobile app in the event of a detected leak. Owners can also utilize an optional shutoff valve accessory to further protect homes. The smart anode adapts to local water conditions, protecting and extending the life of the water heater, and it displays a specific error code on the control panel when it needs to be replaced. Demand response and time-of-use capabilities make it even easier to save money by integrating the heat pump water heater into the growing number of utility smart grid programs.

Heat pump water heaters will continue to play an important role in decarbonization and efficiency efforts. As government agencies put energy efficiency front and center, it’s our responsibility as manufacturers to prioritize more sustainable technology for our customers to ensure a greener future.

Blog Authors:

Arthur Smith, Product Coordinator – Specialty Residential, A. O. Smith

Arthur Smith, Product Coordinator – Specialty Residential, A. O. Smith

Francois Lebrasseur, Business Development Manager – Utility Sector, A. O. Smith

Francois Lebrasseur, Business Development Manager – Utility Sector, A. O. Smith

Without proper maintenance, steam and hot-water boilers in hydronic heating systems corrode and become less efficient, leading to additional service calls and a shorter life span. Replacing a heating system can be very expensive, costing home and building owners thousands of dollars. To help prevent this, encourage your customers to spend a little money every Read more

Without proper maintenance, steam and hot-water boilers in hydronic heating systems corrode and become less efficient, leading to additional service calls and a shorter life span. Replacing a heating system can be very expensive, costing home and building owners thousands of dollars.

To help prevent this, encourage your customers to spend a little money every year on services to maximize the life of their heating systems and prolong a significant expenditure.

With that said, there are some best practices when it comes to servicing a boiler not firing up or flushing different types of hydronic heating systems. In such a system, water expands when it is heated and contracts when it is cooled; i.e., enlarges or reduces in volume. Known as thermal expansion, this is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature.

To accommodate thermal expansion, storage is needed within a system. Two types of systems accommodate thermal expansion: a closed loop (sealed) system and an open loop (vented) system.

Before we dive into how and when to flush a heating system, let’s take a closer look at the difference between a closed loop system and an open loop system.

What is a Closed Loop System versus an Open Loop System?

Closed Loop

In short, a closed loop system is closed to the atmosphere. These systems integrate expansion tanks to accommodate the expansion and contraction of water. A closed system also has a built-in, dedicated return line to carry water back to the heating source (usually a boiler), preventing the possibility of warm or cold spots from mixing in the water supply, as happens in an open loop system.

Usually smaller than open loop systems, closed loop systems there take up less space, while assisting with cleanliness, improving water quality, and reducing the entry of oxygen into the system.

As already noted, a closed loop means less potential for water to enter the system, and that decreases the risk of corrosion.

Open Loop

An open loop system is open to the atmosphere and draws water directly from the hot or cold water lines to which it is connected. Open loop systems have an open expansion tank that accommodates expansion and contraction within the system. More evaporation happens with this type of system, leading to more water being introduced and possibly contaminating the system.

While closed loop systems aren’t as common, they are usually older heating systems and often cannot reach higher pressures. As mentioned, these units allow pollutants to enter the system water, so feed and expansion tanks require periodic cleaning. That enables oxygen to enter the system, contributing to corrosion.

The pipework run from the expansion tank location to the mechanical room where the boiler is located can be grueling and will need insulating to protect against freezing. (More on freezing temperatures later.)

When to Flush a System

Flushing A Hot Water System

Newer residential hydronic systems with hot-water boilers are closed-loop. We do not recommend opening and flushing a closed loop system unless you absolutely have to. Why? Because the enemy of such a system is actually oxygenated water.

However, like a car, closed loop hydronic heating systems must be regularly serviced to prevent problems and maintain efficiency. But unlike a car, they don’t cough, stutter, give off smoke or produce a foul odor when something goes wrong. The system just silently continues doing its job, slowly deteriorating in performance and failing much sooner than it should.

However, sometimes the system will provide some clues that it is acting up — like making a rumbling noise as minerals start to collect in the system. After all, a closed system still has a component that feeds water into it if it needs to.

Additionally, your customer might have a system leak that they weren’t aware of, adding oxygenated water to the system for years. That will cause many problems and change the pH level in the system.

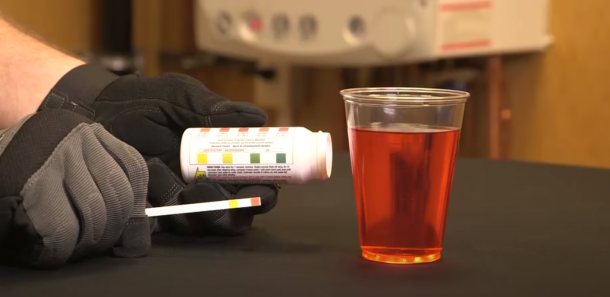

For a closed-loop residential boiler to operate properly, the liquid it circulates must maintain the correct pH levels. To truly identify if you have a potential leak or sludge buildup, you must conduct a pH test to determine if the system should be flushed with a cleaner. We recommend conducting a pH test at least once a year.

Start with a visual reading by opening the drain valve and bleeding off some liquid. If it appears clear, proceed with a pH test. To run a pH test, you can buy test strips that provide a color-coded readout. If you need a more precise reading — say, for an aluminum system — use a digital pH meter.

The correct pH level depends on the composition of the heat exchanger. Systems with a cast iron, stainless steel, or copper exchanger are resilient and usually have a wide range of acceptable levels. Aluminum is more prone to corrosion and may require a specific pH number. Read the system’s installation and operating manual to determine the acceptable pH range. We recommend using a corrosion inhibitor to balance out the pH — a seamless fix. However, if the buildup or corrosion has been going on for several years, the system will probably not recover with this treatment. Instead, you’ll have to use a cleaner to flush the system to maximize boiler efficiency.

Check out this blog that covers the impact of pH in hydronic heating systems and how to test and balance levels.

Flushing A Steam Heating System

Larger steam boilers are usually used in multifamily or commercial applications. Years ago, these large steam boilers held thousands of gallons of water. But, as time went by, steam boilers became more efficient. Today, more compact units are available.

As a steam boiler heats up, water turns into steam and eventually flows through the system. When that steam condensates, it all returns to the boiler. But newer, more compact boilers don’t have nearly the capacity of their older, larger counterparts, so the former run out of water quickly.

Over the years, the industry has developed components to sense when the boiler is low on or out of water. They will shut the boiler down, giving the system time to fill up. So these safety components essentially prevent the unit from firing if it’s low on or out of water.

Some components are electronic. Others involve a ball sitting inside the unit that floats up and down as the water level of the boiler changes.

Timers on these systems will indicate a shutoff for, say, one to three minutes, providing time for all the condensate and water to return to the boiler. Then, if the return water is not sufficient, electronic and solenoid valves will open to let more water in.

That, of course, permits corrosion-causing, oxygenated water into the system. Which is why these safety components must be flushed from time to time, because of the likelihood of mineral buildup.

Which is why steam boilers require regular maintenance and should be flushed with a cleaner or corrosion inhibitor at least twice a year — typically at the beginning and at the end of the heating season.

Preventative Maintenance and How to Flush a Heating System

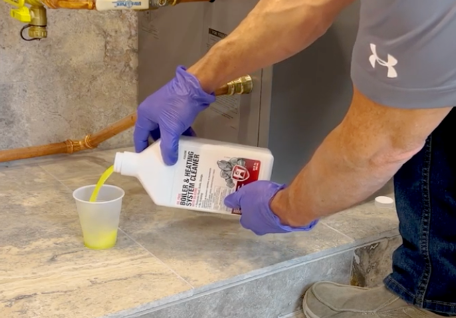

Depending on how dirty the system is and if you don’t want to take it out of operation to completely flush it, we recommend using a cleaner like Hercules® Boiler and Heating System Cleaner. That’s because it can stay in the system and doesn’t require flushing the system.

Hercules Boiler and Heating System Cleaner is formulated to clean and condition all steam and hot-water boilers in hydronic heating systems. The cleaner contains silicone to protect pumps by lubricating seals, maximizing efficiency and preventing valve clogging and corrosion.

Still, be sure to check the pH levels in the system. If the first liquid sample in your visual pH reading contains a lot of rust or sludge, you must take a more aggressive approach by flushing the system with a system restorer. Sludge indicates corrosion in the heat exchanger, fittings or piping.

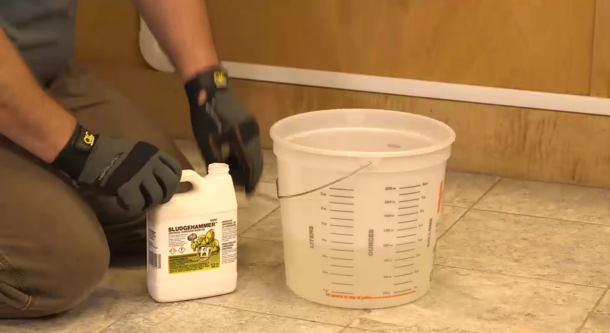

Here’s how to remove sludge:

- Drain off about a gallon of liquid and replace it with three quarts of water and one quart of a system restorer like Hercules® Sludgehammer™ System Restorer & Noise Reducer, which removes scaling and sludge deposits.

- Let the solution circulate for two hours.

- After 2 hours of cycling, dump the system. Leaving the chemical in for too long can damage metal pipes and fittings and ruin the heat exchanger.

- Refill the system with a blend of water and inhibited virgin propylene glycol to prevent corrosion and scale buildup inside the heat exchanger and piping system. Always reference the system manufacturer’s installation and operating manual to ensure you use the proper blend.

Watch this video to learn how to remove sludge and corrosion in hydronic heating systems with Sludgehammer.

While Flushing the System, add Antifreeze

Many contractors use only water in indoor hydronic heating systems. However, water freezes at 32° Fahrenheit; so if there is a power outage, pipes could freeze and burst. In addition, as we’ve learned, water also promotes corrosion and mineral buildup.

Adding an inhibited virgin propylene glycol antifreeze to a boiler corrects both of those problems. Installing inhibited virgin propylene glycol into hydronic heating systems is also a requirement to maintain warranty by leading boiler manufacturers.

The type of antifreeze you’ll need depends on the climate and the metal content of the system.

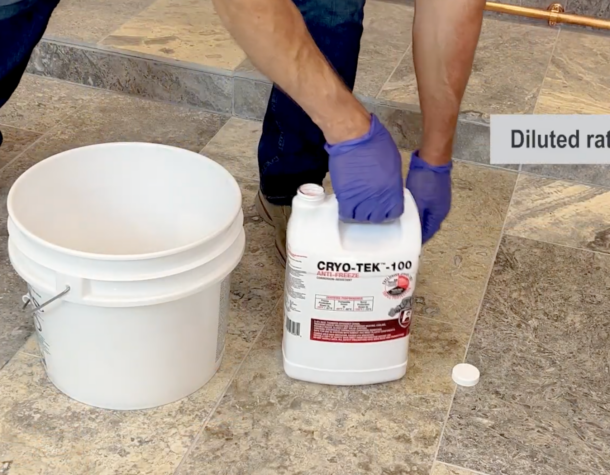

- For cast iron, stainless steel, or copper systems, choose an antifreeze solution like Hercules® CryoTek™ AG, -100, Original or Universal.

- For systems with aluminum heat exchangers, the best choice is an antifreeze that works with any type of metal, such as Hercules® Cryo-Tek™

- Depending on the level of freeze protection required to have an effective and efficient operating system, you can choose blends like Cryo-Tek™ AG or Universal and blend them with distilled water to arrive at the proper freeze protection. Or you can purchase pre-blended formulas like -100 or Original.

The active ingredient of antifreeze is propylene glycol. Avoid antifreeze products that contain “used” propylene glycol, which may introduce minerals and other foreign particles to the boiler. Look for a label that reads “inhibited virgin propylene glycol.”

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.

Author’s biography: Sean Comerford is a Technical Applications Manager at Oatey Co. He is a third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new-construction, service and fire protection jobs. He holds a State of Ohio Fire Protection License for Sprinkler and Standpipe.