It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing. Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his Read more

Uncategorized

It’s been quite the start to 2022 for Ryan Bickerton, owner/operator of Bickerton Plumbing and Heating LLC, Boston. Recently recovered from COVID, his phone hasn’t stopped ringing. He’s been busy, and that’s a good thing.

Mostly specializing in high-end renovations, old houses in the historic areas of Boston and high-efficiency boilers, Bickerton has run his own company since 2014. At the age of 18, Bickerton started into plumbing, working for a larger residential company doing large multi-unit buildings where he worked for 2 1/2 years before moving to a smaller company doing mainly commercial work.

The itch started for Bickerton when he started in construction over the summers during high school, working for a roofing company and a general contractor, basically doing whatever was needed on a job site. “I tried helping whoever needed to be helped on the site—plumbers, electricians, carpenters—cleaning up, making coffee runs, etc. I remember those summers working for the GC and I enjoyed helping the plumbers more than anything else. I realized I was falling in love with the industry, and the rest is history,” says Bickerton.

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Nevertheless, Bickerton was encouraged to make an attempt at college even though he didn’t really want to; he gave it a shot anyway. He lasted less than a year and decided that was it. “For me, it was a waste of time and money,” says Bickerton. “My parents were okay with me leaving after giving it a valiant effort, but my father said ‘pick a trade because you’re not going to be sitting around here all day.’”

Bickerton recalls speaking to his father, and a few other people he knew who worked in the trades, and was pushed in the direction of electrical or plumbing mainly because, “you’ll never be looking for work.”

After obtaining his Journeyman Plumbing and Gas Fitting License in 2008, Bickerton completely shifted gears and joined the United States Marine Corps where he was deployed to Afghanistan. It was a difficult decision but joining the military was something Ryan had always wanted to do. In 2008, it was the right time. After six years of service with the Marines, Bickerton returned to plumbing and got his Master Plumbing and Gas Fitting License. “I started doing more and more side work until I landed a few bigger jobs that motivated me to leap into owning my own company. I haven’t look back since,” says Bickerton.

Part of that drive came from his biggest role model, his father, who worked most of his life in a power plant in South Boston as a general mechanic—he could pretty much fix anything and everything that needed fixing. “My father is the hardest working person I know. I remember as a young kid not seeing him for days at a time because he was getting home late and leaving early before we were awake. I knew he was out working hard taking overtime to provide for us. He could and would fix most things around the house. I remember one year our water heater went out on Thanksgiving and he took care of it by himself. I thought that was pretty cool, and still do,” says Bickerton.

As for Ryan, he never considered himself a role model, but he tries to conduct himself that way. Any chance he gets, he’ll speak highly of the trades. “If any young kids ask me about the trades, I do my best to steer them in the right direction and let them know it’s a very viable option. It’s a rewarding career choice, and college and white-collar work doesn’t have to be for everyone,” says Bickerton.

Bickerton does rough-ins to beautiful renovations.

Bickerton’s trade role model was his first foreman, Mike Sheehan, a plumber for 30+ years, his body broken from years of moving massive boilers and extra heavy cast-iron pipe. “But he still loved the trade. He taught me a lot of my early skills, and he would say that this trade has all the potential to do anything you want with it, which has really stuck with me to this day,” says Bickerton.

Bickerton’s go-to tool has been the ProPress/MegaPress. “Don’t get me wrong, I loved to solder and took great pride in having clean joints, and still think it’s a necessary skill to have, but the press system is a complete game changer.”

While respecting these two men’s work ethic, Bickerton knows that balancing work and family life is important. It’s probably his most difficult task, says Bickerton. “I’m usually out the door by 5 am and home around 5 pm, and the kids go to bed between 7:30-8 pm and then most nights I have to do estimates or invoices when they’re in bed so I don’t have as much ‘leisure time’ as I’d like. I try to make every second I’m home count.”

And the weekends are for family. Bickerton used to work every Saturday and even some Sundays. Lately, however, Ryan doesn’t work Sunday unless it’s a catastrophic emergency, and on Saturdays he tries to be done by 12 or sometimes not at all. “Like I said before, I love plumbing and working but I don’t think I’ll ever regret not working more and spending less time with my family so I try to best divide my time in the fairest manner possible.”

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

It’s clear that family time is most important. “In my spare time, more than anything, I enjoy hanging out with my wife and our children. My wife Micayla and I have been married for six years and our three kids are growing up fast. If I’m not working, I’m with them. They are starting to get into different activities, hockey, baseball, football, swimming, horseback riding, and I just enjoy every second of that. Even if it’s just hanging out and watching a movie, it’s never wasted time for me,” says Bickerton.

Perhaps family means a bit more to Bickerton because his daughter, Mallory, was diagnosed with a rare genetic disorder called Rubenstein Taybi Syndrome (RTS). In 2017, Ryan and Micayla, along with some close friends, started a non-profit organization called Mals Pals Foundation. “We have been very fortunate with Mallory. We live in the epicenter for healthcare; she has had an inclusive educational opportunity here in Boston and it helps that we are able to pay for anything and everything she has needed in order to thrive,” says Bickerton.

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mal’s Pals Foundation aims to ease the burden of other families who maybe are not as fortunate. The Bickertons raise awareness for rare diseases like RTS, and they help educate newly diagnosed families. “We are trying to make difference in other people’s lives even if it’s just a small one. You can check us out at malspalsfoundation.org.”

Mallory is now seven-years-old and doing well. “Initially, there were concerns, but honestly, I wouldn’t have it any other way,” says Bickerton.

Bickerton looks forward to going to work every day. “But the most rewarding to me is being able to sit back at the end of the day or at the end of a job and look at what I’ve done,” says Bickerton. “I like having something tangible, that I can look at and touch and say I did that, or I fixed that or I created that. Whether it’s fixing a leaking faucet, creating a bathroom where there wasn’t one before, plumbing a 5-unit building completely from scratch or providing someone with heat and hot water for the next 20-30 years. That’s pretty cool.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

In the end, Ryan really loves plumbing, even if he’s stressed out and jobs are behind, or he’s behind on paperwork, or he’s made a mistake and or redo something. “I still consider myself lucky to be doing what I love every day. And on those harder work days, I still get to come home to three beautiful children and a wife who loves me. Every time I walk in the door and they scream ‘DAD!’ all that stress lifts off instantly, and it’s all worth it.”

Emerson’s Greenlee team facilitated the field study designed to further enhance worker safety Greenlee, part of Emerson’s professional tools portfolio, is helping municipal utility workers in Knoxville, Tenn. learn how they can benefit from ergonomic health and safety on the job. Greenlee, an industry leader in tools with applied ergonomics, spent several days in the Read more

Emerson’s Greenlee team facilitated the field study designed to further enhance worker safety

Greenlee, part of Emerson’s professional tools portfolio, is helping municipal utility workers in Knoxville, Tenn. learn how they can benefit from ergonomic health and safety on the job.

Greenlee, an industry leader in tools with applied ergonomics, spent several days in the field with Knoxville Utilities Board (KUB) employees studying how they use utility tools in natural gas, electric, water and wastewater projects. As part of the research, KUB members had sensors placed on key pressure points on their bodies. This helped to scientifically measure each user’s energy and form output when working with different tools in various application scenarios.

“We’re showing people literally what their body is going through with every lift, turn and bend they do during the workday,” said Ryan Berg, director of product management, Greenlee for Emerson. “You can talk about how a certain tool is designed to deliver less strain on the body, but it’s not until you see the data from the sensors that it makes sense. We can show the energy each person is exerting and talk about how performing a task differently or using another tool or method could prevent harm to the individual.”

This quantitative data is helping KUB add to its existing ergonomics strategy by showing employees how new tools and work processes have a long-term effect on their bodies.

“In the past, we’ve looked at all the potential for ergonomic improvements, but we’ve not had any measurable data. This is the first time we’ve had real measurable data or have looked into specific tools and tasks to pinpoint our biggest issues and find a feasible solution,” said Hayden Sparks, safety specialist, KUB. “It’s important to understand how our employees use tools and which tools they prefer so that we can give them a better process and better tools to increase their longevity. We want them to take care of themselves in the

long run.”

The KUB field study results are an example of how ergonomic considerations can enhance employee health and safety efforts by showing how the impact of tool selection and other practices in the field can make a big impact. These enhancements can help improve productivity, decrease injuries and save money over time.

Greenlee is dedicated to optimizing and enhancing applied ergonomics in tool design to make work easier and safer for trades professionals.

To learn more, visit Greenlee.com/Ergonomics.

Emerson’s professional tools business includes Greenlee as well as the RIDGID® and Klauke® brands and provides the industry’s broadest portfolio of advanced, reliable tools and technologies for the mechanical, electrical and plumbing trades globally. Visit emerson.com/professionaltools for more information.

A. O. Smith, a leader in water heating and treatment, announced new class dates for its series of October virtual training programs. These classes were added as a result of high-demand for its industry-leading A. O. Smith University educational sessions. The A. O. Smith University class schedule is flexible month-to-month, and sessions are offered on Read more

A. O. Smith, a leader in water heating and treatment, announced new class dates for its series of October virtual training programs. These classes were added as a result of high-demand for its industry-leading A. O. Smith University educational sessions.

A. O. Smith, a leader in water heating and treatment, announced new class dates for its series of October virtual training programs. These classes were added as a result of high-demand for its industry-leading A. O. Smith University educational sessions.

The A. O. Smith University class schedule is flexible month-to-month, and sessions are offered on a variety of topics, including residential training, commercial training, tankless training, and heat pump training. This October, classes will include the following:

- 12, 8 A.M.CST: Residential Training – residential gas and power vent

- 13, 8 A.M.CST: Commercial Training – commercial electric

- 14, 8 A.M.CST: Tankless Training – tankless installation

- 26, 8 A.M.CST: Residential Training – residential electric

- 27, 8 A.M.CST: Commercial Training – commercial gas

- 28, 8 A.M.CST: Tankless Training – application, how it works, troubleshooting

With the onset of COVID-19, most classes shifted to a virtual learning format. Thanks to the state-of-the-art broadcast studio located in Ashland City, instructors provide real-time, full-scope demonstrations on a range of A. O. Smith products and attendees continue to receive the benefit of hands-on training in this virtual environment.

“This past year has placed a tremendous emphasis on digitally-driven education. Through the virtual learning format, we continue to provide valuable resources to contractors and technicians. This new platform allows us to reach a wider audience than ever before,” said Jason Leonard, marketing technology and training manager at A. O. Smith. “We continue to maintain two-way interaction between instructors and class attendees thanks to our state-of-the-art facilities. Instructors work hands-on with the units and provide real-time demonstrations to help technicians and contractors better understand A. O. Smith products.”

The company has two state-of-the-art training facilities, located in Ashland City and Johnson City, Tennessee, which held primarily virtual training sessions over the past year and a half with over 100,000 combined class attendances. Both facilities are utilized to train technicians, contractors, and product representatives on a variety of products and topics.

There is a 50-person cap placed on all sessions to ensure participants have a high-level of engagement with instructors, as well as the opportunity to ask questions throughout the training. This approach helps maintain A. O. Smith University’s focus on techniques and skills to help grow contractors’ careers.

To view the full class schedule and for further information, visit www.university.hotwater.com/virtual-campus/.

“You called the right place! How can we make you smile?” See how easy it was to catch your attention with a simple greeting? You would be surprised how often a simple acknowledgment of the customer will improve an online review. When working in the home service industry, customer service is your brand. It’s what Read more

“You called the right place! How can we make you smile?”

See how easy it was to catch your attention with a simple greeting? You would be surprised how often a simple acknowledgment of the customer will improve an online review. When working in the home service industry, customer service is your brand. It’s what people remember about you long after a job is completed. It’s the thing that can help drive your business to the next level.

As service providers, it is important to realize that, in today’s world, communicating with your customer directly, has become a necessity. With people finally getting a chance to converse face-to-face after a long period of strict social distancing guidelines, the customer wants to get to know you. No longer can we as service providers hide behind the bag in 2021. Which means it’s the perfect season for sharpening our soft skills such as controlling voice patterns and body language now that we are spending more time face to face. These skills are vital when communicating with customers.

Communicating with a customer is about building professional trust. When a customer feels that you have listened to them and understood what they need, they trust that you can accomplish the job and that expectations are clear. That is when the skills we’ve mastered as service providers come into play, and we follow through with what we promised our customers. This allows your team to ask the customer for additional and referral business, as well as that five-star review that will help create credibility online.

The Wow Factor

The No. 1 rule of any service provider is to go above and beyond expectations. We call this the “wow factor.” The wow factor is doing something extra without expectation; meaning don’t tell the customer you’re going to do it as part of the job. Instead, tell them you did it to say, “thank you.” These don’t have to be major jobs either. It can be as simple as changing air filters when repairing an HVAC unit. The key to this is to start the job the customer paid you to do, add something extra to the deal and then let the customer know at the end. Effectively communicating this is also paramount. Don’t make it look like the extra job was a hassle. Use proper body language and tone to show the customer you were excited and happy to do the job. The technician needs to list this “wow factor” on their invoice at full price then discount it off showing the customer that you are saying “thank you” by going ahead and covering that expense today.

The Good, The Bad, The Lost Customer

It’s funny. Research shows us that the No. 1 reason a customer leaves any company and finds a replacement is a lack of customer service. When there is poor communication, the customer doesn’t feel that he or she has been truly heard. Customer service is about communicating with the customer in a simple form and ensuring they know you’re listening. Using soft skills to keep the customer engaged is key. Not only will it reaffirm they are your No. 1 priority, but it will also help avoid potential conflicts with the customer. If they feel listened to and acknowledged, they will become customers for life and begin to send referrals your way.

The Golden 3

So, after all this discussion, you are probably wondering what are the most important soft skills a service provider should understand and master to improve customer service and satisfaction. In my experience, there are three:

- Listening to the customer: Listen to the customer’s whole question before thinking about how you are going to respond. If a customer finishes their entire question and you already know the answer, then there is a good chance you didn’t actually listen. One thing that we have learned is most field staff stop listening to the customer in the first 10 words that are said. Most customers don’t say what they mean until the last 10 words. So, oftentimes technicians think they are working in the right direction, and they’re working on the completely wrong thing. Following this rule helps ensure all parties’ expectations are clear.

- Skillset training, both technical and communications: We are creatures of regression. We automatically lose things that we don’t practice or sharpen. Making sure you are setting time aside as a company for all your field staff to sharpen their technical and soft skills multiple times a week (even if it’s only 15-30 minutes) helps to limit their loss of knowledge.

- The ability to shut up: This is probably the most important skill a field tech can learn. When you ask a customer a question, STOP and wait for their response. When a technician asks a question, they tend to get uncomfortable with the silence. So, the tech ends up asking another question to break the silence, which in turn completely breaks the customer’s train of thought. It’s important to know that when you ask a question and then SHUT UP it may be uncomfortable for you, but it’s not for the customer. It doesn’t register as silence to the customer because they are still processing the information you just presented. So, learn to shut up and let them finish their process…respectfully.

If you can follow these three simple rules and processes, I’m confident you will improve your customer service skills and help retain customers while gaining some new ones, too.

Matt Koop is Vice President of Training and Implementation for The New Flat Rate, a home service menu-selling system designed to put profit directly into the hands of plumbing, electrical, and HVAC contractors. For more information visit www.thenewflatrate.com or email info@menupricing.com.

Matt Koop is Vice President of Training and Implementation for The New Flat Rate, a home service menu-selling system designed to put profit directly into the hands of plumbing, electrical, and HVAC contractors. For more information visit www.thenewflatrate.com or email info@menupricing.com.

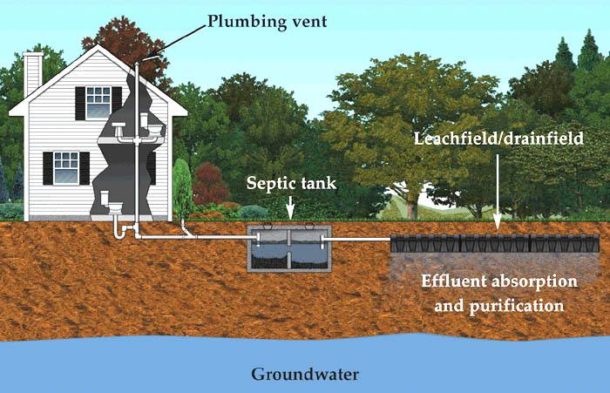

Dealing with a blocked septic line or septic system can happen from time to time. Usually, it’s nothing more than clearing a clogged sink or toilet. When that doesn’t work, you might have a bigger problem on your hands. One of the possible problems is a broken septic pipe. Learn how to determine if you Read more

Dealing with a blocked septic line or septic system can happen from time to time. Usually, it’s nothing more than clearing a clogged sink or toilet.

When that doesn’t work, you might have a bigger problem on your hands. One of the possible problems is a broken septic pipe. Learn how to determine if you have a broken septic pipe and what your options are to fix it.

How Do I Know If My Septic Pipe is Broken?

Before assuming the pipe is broken, try to see if there’s a clog in the pipe. Things like toilet paper, hair, or even kitchen grease can cause clogged pipes. You might also notice slow drains or a sewer odor inside your house. Using a plunger, chemical drain cleaner, or plumbing snake can all be used to clear the clogged pipe.

Don’t forget to check drains for your washing machine, dishwasher, or other sinks you might have in your home. Those appliances can also have a slow drain that you might not notice right away but can indicate a problem.

If that doesn’t seem to resolve the problem, it’s time to contact a professional. Continuing to use a snake or chemicals can cause damage and make the situation worse and possibly more expensive.

Another one of the telltale signs your septic system is broken is a soggy area in your yard. You may also notice a foul smell while you’re outside. If you’re familiar with where your sewer pipes or septic tank are located, it can help you confirm this is the problem.

While a clog may not break the sewer pipe on its own, repeated clogs can damage the pipes. Tree roots are known to cause a damaged sewer line and you may not know anything is wrong until there’s a big problem.

A licensed professional plumber can come out and take a look at the sewer lines by doing a camera inspection. This will allow them to see exactly where the issue is and what’s causing the problem even in spots that wouldn’t be otherwise visible.

Broken sewer lines can cause health issues and additional damage to your home that can be more expensive. It’s important to have these repairs made right away to keep your family safe and avoid a more expensive repair because of more damage.

Can I Repair a Broken Septic Pipe?

Depending on the damage, you may be able to repair just the broken section of pipe you find. Homeowners who have older septic systems may want to go ahead and replace the entire septic system when damage is found. It might be a more expensive option now, but wind up saving you money in the long run.

If you decide to try to find the broken pipe yourself, it’s important to be very careful when digging up your yard to locate the broken area in the pipe. A shovel can cause a cracked sewer pipe that might not have been damaged before. These cracks letting surrounding soil in can cause even more damage to the septic system.

You may notice sewage backup at the broken lines or near your septic drain field. In addition, you might be able to smell sewer gas near the broken lines. These things can help you locate the general area of broken sewer lines in your yard.

After you find the broken line, it might be obvious that there’s a clog that’s easily fixed. Be sure to wear gloves to keep your hands protected from any sharp objects or sewage that may be present.

Contacting a professional plumber to repair the pipes is another option. Because they’re experts, they’ve handled a situation like yours before and know exactly what needs to be done to repair your broken pipes. When you contact a plumber, they’ll let you know your options regarding repairing versus replacing the sewer lines.

PVC or metal pipes can be repaired by sealing the pipes back together with an epoxy or other pipe sealant. Concrete pipes will need to be repaired with mortar. Your home may also have clay sewer pipes. These pipes can be patched as well.

What Does Fixing a Broken Septic Pipe Cost?

Once you’ve found the location of the broken pipes, you can start gathering information to request a quote from a plumber for the sewer line repair and replacement options. Several different things will need to be taken into consideration when a professional plumber provides a quote.

One of the first things to look at is the location of the damage. If the damaged pipes are on public property, you’ll need to contact the proper authorities to have the damage repaired.

On average, the cost to repair sewer lines is $2500, with the average range being $1100 – $4100. Smaller repairs will obviously be less expensive, while repairs that require trenches to be dug or complete replacement of your entire system will be much more expensive.

Your plumber will let you know what the necessary repairs are that need to be made to make your sewer system functional again. You may want to just make the repairs but might actually save money replacing your current plumbing system. Doing proactive maintenance on your septic system will help catch smaller problems before they become a larger issue to deal with.

Repairs can take a few hours or a few days to complete depending on the severity of the clog and damage, what your pipes are made of, and if repairs or a replacement are happening.