Bryant, a leading provider of high-quality heating, ventilation, and air conditioning solutions, is proud to announce the successful conclusion of its 120th anniversary celebration, having raised $113,000 in support to food banks affiliated with Feeding America. Through a year-long campaign of charitable donations and volunteer hours, Bryant has made a significant contribution to the fight Read more

HVAC

Bryant, a leading provider of high-quality heating, ventilation, and air conditioning solutions, is proud to announce the successful conclusion of its 120th anniversary celebration, having raised $113,000 in support to food banks affiliated with Feeding America. Through a year-long campaign of charitable donations and volunteer hours, Bryant has made a significant contribution to the fight against hunger, helping communities across the nation. Bryant is a part of Carrier Global Corporation (NYSE: CARR), global leader in intelligent climate and energy solutions.

Over the course of 2024, Bryant employees, distributors, and dealers collectively raised money for Feeding America. Bryant kicked off efforts with a $50,000 donation; the rest was raised through individual contributors and 17 partners from seven states. These funds will be distributed to food banks across the country, providing critical resources to individuals and families in need. The company’s commitment to fighting food insecurity goes beyond financial support, with more than 600 volunteer hours dedicated to local food banks.

“We are incredibly proud of the impact we were able to make in our 120th year,” said Nick Arch, Vice President and General Manager, Residential HVAC Solutions, Bryant. “Exceeding our volunteering goal was a testament to the generosity and strength of the Bryant network. Our commitment to supporting Feeding America will continue to grow as we work together to ensure that no one goes hungry.”

Throughout the year, Bryant’s employees, and affiliates packed food donations, supported mobile pantries, drive-thru pantries, and other food distribution efforts, and launched a social media campaign. These efforts were aimed at providing immediate assistance while also raising long-term awareness about the issue of food insecurity.

Bryant’s support of Feeding America is part of the company’s broader Corporate Social Responsibility (CSR) program, which focuses on making a positive difference in communities where Bryant operates. Through initiatives like these, Bryant strives to leave a lasting impact on both local and national levels, demonstrating its commitment to creating a better future for all.

Feeding America, the nation’s largest hunger-relief organization, provides millions of meals each year to people facing food insecurity. By supporting Feeding America, Bryant has directly contributed to the organization’s mission of providing food to individuals and families in need.

To learn more about Bryant’s ongoing support of Feeding America and the renewed commitment to support in 2025, visit https://www.bryant.com/en/us/about-bryant/community-involvement/.

This Is Part 1/2 of Building a Sustainable Future with Thermal Energy Networks by Marc Miller, Egg Geo, LLC Modern energy demands are growing, and the need for sustainable, efficient solutions to heat and cool our homes and businesses has never been greater. Enter Thermal Energy Networks (TENs)—innovative systems that distribute and reuse energy to Read more

This Is Part 1/2 of Building a Sustainable Future with Thermal Energy Networks by Marc Miller, Egg Geo, LLC

Modern energy demands are growing, and the need for sustainable, efficient solutions to heat and cool our homes and businesses has never been greater. Enter Thermal Energy Networks (TENs)—innovative systems that distribute and reuse energy to reduce costs, cut emissions, and optimize performance.

Image: Eversource

This article explores the basics of TENs, their benefits, and real-world applications, helping you understand their potential to transform energy systems for the better.

What Are Thermal Energy Networks?

At their core, TENs are district energy systems that use ambient temperature loops (ATLs) to share heating and cooling between buildings. These loops typically circulate a heat transfer fluid, such as water or a water-propylene glycol mixture, at a temperature range of 50°F to 85°F. By tapping into diverse thermal sources, such as geothermal wells, waste heat recovery, or natural water bodies, TENs provide sustainable, cost-effective alternatives to traditional heating and cooling systems.

Crucially, TENs optimize thermal sharing between stakeholders:

- Consumers exclusively use thermal energy.

- Prosumers both produce and consume energy (e.g., offices that generate heat and reuse it internally).

- Generators supply thermal energy into the network (e.g., geothermal wells or industrial processes).

How TENs Are Different?

Unlike traditional systems like two-pipe or four-pipe setups of district heating and cooling scenarios, TENs use an ambient one-pipe loop that operates at variable fluid flow and temperatures instead of relying on constant temperature and variable flows. Here’s what sets TENs apart:

- One-Pipe Systems manage heating and cooling directly by varying the flow of the fluid of varying temperature circulating the loop.

- Efficiency in Pumping reduces energy waste with self-balancing, simpler designs that eliminate the need for balancing valves. This results in significantly lower operating and installation costs.

- Pump Controlled Instead of Valve Controlled. No balance valves or control valves are used. Flow through decoupled secondary loops is managed by a pump sized to deliver the optimal flow.

Key Benefits of TENs

Energy Efficiency

TENs enable efficient thermal load sharing and shedding. For example:

- Unused heat from one building can be redistributed to another, maximizing energy use across the network.

- Water source heat pumps (WSHPs) leverage the stable temperature of ATLs, operating with coefficients of performance (COP) ratings of 3–5, which translate to lower energy consumption.

Cost Savings

Compared to traditional systems, TENs offer significant financial benefits:

- Lower Installation Costs: With single-pipe systems, there’s less piping, no balancing or control valves, and reduced labor for installation because of less fittings, less tooling and overall less pipe. Additionally there is a single pipe size for the entire loop.

- Reduced Operating Costs: Circulating water at ambient temperatures requires much less pumping power.

Scalability and Flexibility

TENs are highly scalable—there’s no limit to the number of stakeholders that can connect to an ATL. The caveat is that when sizing the loop, it must be sized for the total load to include anticipated future expansion. The more buildings added, the better the system operates due to improved thermal diversity, which counterbalances the temperature cascade effect (where fluid temperatures progressively change as they circulate).

Environmental Impact

Integrating geothermal energy with TENs significantly reduces greenhouse gas emissions. By shifting away from fossil-fuel-based heating systems, TENs pave the way for a green and sustainable future.

Real-World Example

The Eversource Geothermal Pilot in Framingham, Massachusetts, is a first-of-its-kind utility-scale networked geothermal project. Launched in 2024, this system connects 135 residential and commercial buildings, providing ground-sourced heating and cooling through an ambient temperature loop.

Key takeaways from this pilot include:

- Reduced reliance on fossil fuels, replaced with renewable energy from earth’s natural thermal stability.

- Positive feedback from participating stakeholders due to noticeably reduced energy costs and environmental impact.

- A replicable model for other communities to follow.

“This project… is enabling our team to see how we can provide services in a completely new way,” shared Bill Akley, President of Gas Distribution at the project’s groundbreaking.

Challenges and Considerations

No system is without challenges, but TENs offer practical solutions for common concerns.

- Temperature Cascade Effect: Concerns about progressive temperature changes are resolved by system diversity. More connected stakeholders create a smoothing effect that distributes thermal loads more evenly.

- Initial Investment: Modern legislative incentives and community grants, like those funded by the U.S. Department of Energy, are now making upfront costs more affordable for communities adopting TENs.

How TENs Function, a Simple Explanation

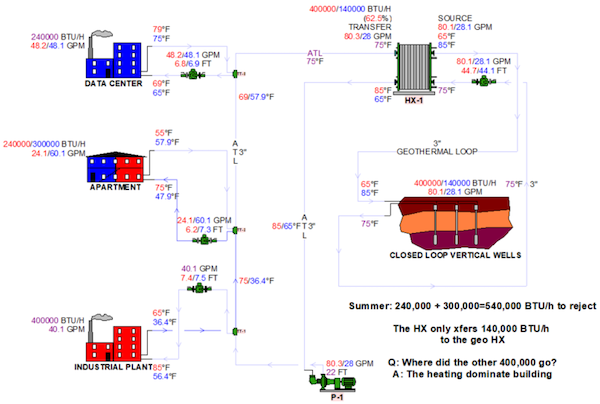

In the first illustration below, a TEN utilizing its one-pipe Ambient Temperature Loop (ATL). The TEN consists of a geothermal source/sink, an intermediary heat exchanger, a main loop distribution pump, and three stakeholders: a cooling-dominant data center, a heating-dominant industrial plant, and an apartment building with relatively balanced heating and cooling loads.

During the summer, the network manages a total heat rejection of 540,000 BTU/h from the apartment building and the data center. However, only 140,000 BTU/h is transferred to the geothermal sink via the heat exchanger (HX-1). This reduction occurs because the network redirects excess heat to the industrial plant, utilizing it for productive purposes rather than rejecting it to the ground.

In winter, the network requires a total of 640,000 BTU/h to meet the heating demands of the apartment building and the industrial plant. Of this, 400,000 BTU/h is supplied by the geothermal source through HX-1, while the remaining 240,000 BTU/h is provided by the data center, offsetting the geothermal demand. This demonstrates the network’s ability to efficiently balance loads by redistributing energy among stakeholders.

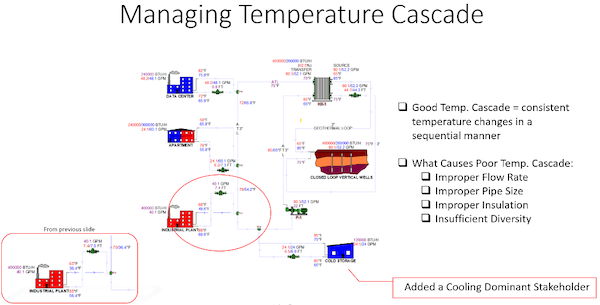

In the second example below, we introduce a cooling-dominant load of approximately 10 tons (120,000 BTU/h) to the loop. The system is designed to maintain a leaving heat exchanger temperature of 65°F and a return temperature of 75°F, preserving a 10°F delta T. This consistency is achieved through pump control. By increasing the pump speed and actively managing water flow through the heat exchanger based on temperature, the system sustains the desired 10°F delta T. foundational principles of a TEN.

The performance of such a network improves with greater load diversity, i.e., the inclusion of more stakeholders with varying thermal profiles. Additionally, since the system is pump-controlled and does not rely on balancing valves the system is self-balancing. In fact, the temperature cascade effect is shown to improve with an increasing number of thermally diverse stakeholders connected to the loop.

In the previous scenario, the pump’s flow rate was 28 GPM. With the added load, it increases to 54 GPM. Additionally, the inlet temperature to the industrial plant rises from 56.4°F to 69.6°F. Even with the extra 10 tons of cooling load, the pipe size for both the geothermal source/sink loop and the ambient temperature loop remains 3 inches. Importantly, the return temperature to the heat exchanger remains consistent at a 10°F delta T with a 75℉-return design temp.

By examining the ambient temperature loop (ATL), we observe that the temperature range improves significantly, aligning with the target range of 55°F–85°F. Previously, when there were only three loads, the loop’s temperature immediately after the industrial plant was much lower at 36.4°F. Furthermore, the heat transfer through HX-1 and the geothermal well field increases substantially, from 140,000 BTU/h to 260,000 BTU/h, reflecting the additional 10 tons of cooling load.

It is worth noting that this theoretical scenario assumes no other consumers of waste heat, providing just a snapshot in time. In practice, there will always be various heat consumption requirements, such as domestic hot water production, pool heating, or snow melting. Thermal energy networks (TENs) are designed not only for heating and cooling but also for these additional purposes. As a result, the BTUs from cold storage will be utilized across multiple applications beyond simple heating or cooling thus keeping the amount of heat to be rejected by HX-1 to a minimum

This simplified explanation underscores the system’s ability to adapt to increased loads while maintaining efficiency and highlights the versatility of thermal energy networks in meeting diverse energy demands. In part 2 of this article, we will dive into the specifics of how to connect your home or building to the TEN with a decoupled secondary loop and talk about how to control the pump to account for Thermal Diversity and Temperature Cascade Effect.

Marc Miller is a Mechanical Systems SME – Educator – Technical Writer – Author – Construction Management Consultant with Home – Egg Geo. He is presently the Lead Author on two textbook projects with Egg Geo. He may be reached at marcm@egggeo.com.

Marc Miller is a Mechanical Systems SME – Educator – Technical Writer – Author – Construction Management Consultant with Home – Egg Geo. He is presently the Lead Author on two textbook projects with Egg Geo. He may be reached at marcm@egggeo.com.

https://vimeo.com/1063068523 On this week’s update, we’ll talk U.S. infrastructure and what the current state of that looks like, World Plumbing Day, we’ll feature some of our AHR visits and a new contractor spotlight with Shawn Ziegler, Accurate Mechanical out of Lancaster, Ohio. Plus, we’ll talk new, weekly podcasts. Oh, and I almost forgot, Gate Lice Read more

On this week’s update, we’ll talk U.S. infrastructure and what the current state of that looks like, World Plumbing Day, we’ll feature some of our AHR visits and a new contractor spotlight with Shawn Ziegler, Accurate Mechanical out of Lancaster, Ohio. Plus, we’ll talk new, weekly podcasts. Oh, and I almost forgot, Gate Lice.

A former star middle linebacker for the University of Toledo, which progressed to the Marion Mayhem indoor professional football team, and then to an All-American middle linebacker for a semi-pro football team for nearly 10 years, Shawn Ziegler has now turned to boxing. After some time had passed after his football career, he started working Read more

A former star middle linebacker for the University of Toledo, which progressed to the Marion Mayhem indoor professional football team, and then to an All-American middle linebacker for a semi-pro football team for nearly 10 years, Shawn Ziegler has now turned to boxing. After some time had passed after his football career, he started working out and getting back into shape, when his buddy messaged him and asked if I wanted to try out boxing, Being the competitor that he is, Ziegler said yes. He’s had three fights so far and, you guessed it, he’s undefeated.

A former star middle linebacker for the University of Toledo, which progressed to the Marion Mayhem indoor professional football team, and then to an All-American middle linebacker for a semi-pro football team for nearly 10 years, Shawn Ziegler has now turned to boxing. After some time had passed after his football career, he started working out and getting back into shape, when his buddy messaged him and asked if I wanted to try out boxing, Being the competitor that he is, Ziegler said yes. He’s had three fights so far and, you guessed it, he’s undefeated.

Ziegler is uncertain if he’ll fight again, but he’s not closing the door entirely. It’s tough to get in the ring at the age of 40, says Ziegler, especially after playing football for so many years. “I’m a 40-year-old living in 60-year-old body, but I wouldn’t trade it for anything. I’ve enjoyed every moment of my athletic career,” says Ziegler.

Ziegler is uncertain if he’ll fight again, but he’s not closing the door entirely. It’s tough to get in the ring at the age of 40, says Ziegler, especially after playing football for so many years. “I’m a 40-year-old living in 60-year-old body, but I wouldn’t trade it for anything. I’ve enjoyed every moment of my athletic career,” says Ziegler.

For the past five years, Ziegler has been the mechanical piping field supervisor for Accurate Mechanical, Inc., Lancaster, Ohio, which includes dabbling in mechanical piping and equipment installation—boilers, chillers, air handlers, cooling towers and VRF systems. “My crew and I can do it all,” says Ziegler.

From the Jump

Ziegler has always been a part of the trades, as long as he can remember. “My grandfather and my father were both involved in the trades; my father was a brick, block and stone mason, so I was introduced to the labor force at the ripe old age of five. I can remember tagging along with dad on side jobs and him putting me to work mixing mortar,” recalls Ziegler.

From an early age, Ziegler’s grandfather and father taught him what it meant to work for the things you want in life. “They shaped me into a man, and I didn’t even realize they were doing so,” says Ziegler.

As a young adult, Ziegler worked a few different trades after his college football career ended. He worked in concrete, masonry, and demolition before, what he says, “stumbled upon plumbing.”

“I was laid off from my demolition job where I was making I measly $10 an hour so I talked to a buddy who was in a plumbing apprenticeship and he said the company was looking for new apprentices. So, I signed up, and the rest is history,” says Ziegler.

That history was defined by his journey into plumbing and pipefitting nearly 16 years ago. “Within those 16 years I’ve worked my way through the trenches and into a good role as the field supervisor where I over see a crew of 10 pipefitters,” says Ziegler.

He began as a plumbing apprentice in 2008 and graduated from the Association of Plumbing and Hydronic Contractors (APHC) apprenticeship program in Central Ohio in 2012 near the top of his class. Although, Ziegler says he found out quickly he enjoyed working in the HVAC industry more than the plumbing industry. “I started my HVAC career in 2010 after only two years plumbing. I’ve always been a bigger and stronger guy than most of my co-workers, so I was always put on the jobs where heavier lifting was required. Now I’m in a position near the top of my trade,” says Ziegler.

As a pipefitter, Ziegler’s No. 1 tool will always be a RIDGID pipe wrench. But with the magnitude of some of his jobs—a lot of big commercial, industrial work—Ziegler uses a wide variety of tools, including grooving machines, big hydraulic cutters, thread machines, and his crew uses a lot of rigging tools to set their equipment into place. “Most companies hire sub-contractors to move and set their HVAC equipment, not us we pride ourselves in the fact that we can do a job from start to finish,” says Ziegler.

Ziegler currently is taking college classes to get his business management degree, in hopes to continue his climb to the top of his career.

Paying Homage

Ziegler does want to send a shout out to a few great men that helped develop him into the professional that he is today. The first nod goes to an old man named Dave Boehringer. He was a senior piping foreman that Ziegler worked with for nearly 10 years. “He may be one of the smartest and hardest working men I’ve ever known. Dave taught me what hard work and dedication was all about. He had a way to reach out and pull the young apprentices in, and he was great teacher of the trade. I was blessed to have a foreman like him in my early years,” says Ziegler.

The next gentleman is Andy Jacobs. He took a chance on a young man that didn’t know which direction was up at the time. Jacobs hired Ziegler, just as he was stepping away from plumbing, as a journeyman pipefitter at a company named Engineering Excellence, a service-based company that specializes in HVAC retrofits. “I learned a lot during my eight years there. I have worked with Andy off and on for nearly 10 years, maybe more. And to this day, he is one of my best buddies,” says Ziegler.

The Younger Generation

Yet, Ziegler sees himself as a role model for people looking to get into the pipefitting trade. He regularly attends career days and talks to the younger generation. He also coached high school football for many years, helping several of his young athletes get into the trades.

“The best thing we can do to attract the youth to the trades is treat them the right way. Remember that they are young and learning something new. Make them feel as if they are wanted and appreciated. That goes along way,” says Ziegler.

In addition, Ziegler’s message to the younger generation trying to get into the trades is to stick with it no matter what. “Times will get tough, the pay sucks starting out, but if you do your best and apply yourself in everything you do, it will all work out in the end. The best thing they can do is listen to those above you,” says Ziegler.

What does Ziegler like the most about his work? The biggest reward Ziegler’s gotten while on a job is someone from another trade complimenting him on his craftsmanship, telling him that something I installed is the best they’ve seen; however, the most challenging things he faces now are completing job on schedule with limited manpower. “I have a great crew, but I would love to be able to clone the guys I have now and double my crew,” says Ziegler.

Work/Life Balance

Ziegler says that it is very important to balance work and life, but often times that’s hard to do. “This may be a better question for my wife,” says Ziegler. His spare time is spent reading—Stephen King novels are his favorite—and helping his wife take care of their 5-acre hobby farm where they raise rabbits, and chickens, ducks, and his five Great Pyrenees dogs that they have rescued over the years. “We are a busy family. I work, go to school, help on the farm, and help raise our two disabled children. So, time is a tough thing to find sometimes,” says Ziegler.

And, Ziegler tries to keep in the best shape as he can. “Working out and staying in shape helps the mind and body tremendously,” says Ziegler. “I struggle sometimes to stay motivated, but when I’m working out it delivers a peace of mind. It’s always nice to be in some sort of shape while working as a pipefitter. We do a ton of heavy lifting while we are installing.”

And, Ziegler tries to keep in the best shape as he can. “Working out and staying in shape helps the mind and body tremendously,” says Ziegler. “I struggle sometimes to stay motivated, but when I’m working out it delivers a peace of mind. It’s always nice to be in some sort of shape while working as a pipefitter. We do a ton of heavy lifting while we are installing.”

At the end of the day, it’s that balance that helps him enjoy the good life. “When I wake up in the morning, I always tell myself that today is going to be a great day. No matter what challenges may lay ahead of me. I’m truly blessed to work in a trade that I enjoy. I think I actually enjoyed it more when I was physically doing the work in the field, but I love to be able to teach and help my apprentices grow into productive tradesmen.”

There’s something undeniably satisfying about getting a great deal – it might be snagging a discount on a new gadget or finding a cheaper alternative to an expensive service, or loads of other possibilities, but the point is that saving money always feels like a win. But when it comes to plumbing supplies, cutting corners Read more

There’s something undeniably satisfying about getting a great deal – it might be snagging a discount on a new gadget or finding a cheaper alternative to an expensive service, or loads of other possibilities, but the point is that saving money always feels like a win. But when it comes to plumbing supplies, cutting corners can absolutely end up costing you more in the long run – and that’s not a win at all.

At first glance, it’s easy to think that all pipes, fittings, and fixtures are pretty much the same. After all, they all serve the same function, so why wouldn’t you go for the cheaper option? However, the reality is that not all plumbing supplies and materials are created equal, and skimping on quality can lead to frustrating, expensive, and sometimes even disastrous consequences.

With that in mind, keep reading to find out why the idea that cheaper is better isn’t the right one when it comes to plumbing supplies, and spending a little more initially can save you from a lot of headaches and problems later on.

Cheap Materials Have A Short Lifespan

One of the biggest problems with bargain plumbing supplies is that they just don’t last – lower-cost materials are often made from thin plastics or lightweight metals, for example, and these are things that can’t stand up to the constant wear and tear of water pressure, temperature changes, damp conditions, and so on. True, they might be fine at first so you think it’s all okay, but it’s really only a matter of time before they start to crack, corrode, or degrade.

A low-quality pipe or joint might seem like a great deal when you’re buying it and especially when you’ve got a budget to stick to, but when it fails a few months later and floods the kitchen, the money you saved is going to disappear very quickly. And that’s just the beginning of the problem – the cost of replacing that failed pipe or whatever it was is one thing, but water damage, mould growth, and emergency plumbing fees are going to add up very quickly.

Leaks Lead To Bigger Problems

A small drip from a cheap tap or a tiny leak in a poorly fitted pipe probably won’t seem like a big deal – annoying, yes, but nothing too important to think about. However, given enough time, that little issue can become something much bigger and much more costly to deal with. Water has a sneaky way of finding its way into walls, floors, hidden spaces, even your electrics, and when it does that, it’ll cause untold damage that you won’t be able to see until it’s too late.

Mould loves damp places, and once it starts growing behind walls or under flooring, it’s tough – and expensive – to remove. Then there’s structural damage to think about, and that’s a real nightmare to contend with. It water gets into a wooden beam or your drywall, it can weaken your entire home, which might sound dramatic, but it’s really something that can happen.

Poor Fittings Mean Constant Repairs

When plumbing components don’t fit together properly, you end up dealing with loose connections, weak seals, and recurring leaks… not good in any way, shape, or form. It’s all because cheap materials don’t hold up well to change, so if you need to tighten something, adjust it, or there are temperature changes (which there will usually be with plumbing as water temperatures change a lot in general), so you’re going to always be going back to the same problem time and time again and trying to fix it. That’s going to take time, effort, and money, and all those things can be in short supply.

Instead of buying supplies that need to be replaced every few months, it makes so much more sense to invest in high-quality and much more durable materials and supplies – choose ones that will last for years of being used all the time, and just think about all the problems that’s going to prevent. Yes, you will need to spend more when you buy it, but when you’ve got cheaper materials, you’ll have to spend more to replace it, fix it, and deal with the problems they cause, and that’s probably going to end up costing more than just buying the good stuff right at the start!

Cheap Fixtures Waste Water And Energy

Low-cost plumbing supplies, like taps, showerheads, toilets, and so on, often aren’t all that great at water flow regulation – that’s something that tends to cost a little more. So that means they either use far more water than they should, or they’ll have low water pressure, which is truly frustrating. And all of these things make life a lot harder when you just want things to be easy and have a nice bathroom, ensuite, cloakroom, kitchen… you get the idea.

Want a great shower that really wakes you up? Don’t buy a cheap showerhead or you’ll end up with a trickle of water that you’ll hate. Want an efficient toilet? Spend a little more because a cheap toilet is probably going to need more than one flush and that’s wasting water (and time if you’ve got to wait for the tank to refill). What we’re saying is that these cheaper items are increasing your utility bills over time, and that means those initial savings are going to get eaten up – you won’t have saved anything and will probably pay more. Pay more at the start, and save money on your bills – that’s a much better way round to do it, especially as you’ll be kinder to the planet at the same time.

Emergency Repairs Are Expensive

One of the biggest hidden costs of using cheap plumbing supplies is the potential for having to deal with an emergency repair situation – after all, when a ‘bargain’ pipe bursts in the middle of the night, or a cheap valve fails and you don’t spot it at first, you’re going to have to pay for experts to come and sort out the problem, and that’s not usually going to be cheap.

Unlike planned maintenance or scheduled upgrades, emergency repairs tend to cost more (especially if they’re out of hours), and what started as a fantastic way to save some money and still get the job done ends up being one of the most expensive mistakes you can make. It’s better not to tempt fate and just do it well from the very start.

You’ll Compromise Safety

So we’ve talked – a lot – about the financial costs of cheap plumbing supplies, but the fact is these cheaper items can also be an issue when it comes to safety, so even if money isn’t your main concern and you’re happy to keep paying out for fixes, you’ve got to admit that you want a safe place to live, haven’t you?

So what’s the issue? Well, poorly made components can lead to contaminated water, gas leaks, or even problems with the structural integrity of a building – that’s not good. And it’s why the plumbing industry has such strict regulations about things, and why ignoring those regulations to save a little money can actually put your home and family at risk.

A great example of durable and reliable construction materials can be seen in cities – for example, manhole frames and covers are circular and made of cast iron because they need to be incredibly strong, weather-resistant, and long-lasting. If corners were cut on these types of things, the failures would be awful and potentially life-threatening, so it just can’t be done. Plus, the constant repairs would cost a huge amount, and that would put taxes up for everyone – no one’s going to be happy with that. So why not apply the same principle to your home? It could make all the difference and it’s sure to make purchasing decisions a lot easier too.