North America’s most efficient water heater qualifies for the highest level of energy rebates and can save homeowners hundreds of dollars upon purchase. Rheem recently unveiled the industry’s most efficient hybrid electric water heater. Named ProTerra™ for its unmatched efficiencies, this ENERGY STAR® certified water heater from Rheem is over 400 percent more efficient compared to Read more

HVAC

North America’s most efficient water heater qualifies for the highest level of energy rebates and can save homeowners hundreds of dollars upon purchase.

Rheem recently unveiled the industry’s most efficient hybrid electric water heater. Named ProTerra™ for its unmatched efficiencies, this ENERGY STAR® certified water heater from Rheem is over 400 percent more efficient compared to any standard electric tank-type water heater in market and is more eco-friendly than ever at up to 4.0 UEF.

Rheem recently unveiled the industry’s most efficient hybrid electric water heater. Named ProTerra™ for its unmatched efficiencies, this ENERGY STAR® certified water heater from Rheem is over 400 percent more efficient compared to any standard electric tank-type water heater in market and is more eco-friendly than ever at up to 4.0 UEF.

“Rheem is committed to developing cutting-edge products that benefit end-users and our environment,” said Ankur Maheshwari, senior product manager, Rheem. “Our top-of-the-line ProTerra water heater can save homeowners money upon purchase in the form of a $300 federal tax credit, and because the system requires minimal power to operate, its carbon footprint is the lowest in its class.”

The ProTerra’s compact design makes it a perfect tank replacement for even the home’s smallest spaces. The system is available in the widest selection of gallon sizes in its category – 40, 50, 65, 80 – to support various hot water needs, and the ProTerra with LeakGuard™ model is now the industry’s only hybrid water heater with built-in leak detection and auto-shutoff that limits water loss from the tank to no more than 20 ounces. LeakGuard protects the home against water damage, providing peace of mind for end-users.

This all-new hybrid water heater also has Rheem’s exclusive EcoNet® Wifi technology built in. Once connected through the EcoNet mobile app, users can monitor the system from any location, adjust water temperatures for controlled comfort and receive maintenance alerts to ensure the system continues to run smoothly without interruption. Additionally, through the EcoNet mobile app, users can access Rheem’s Hot Water Availability feature which indicates how much hot water is available in the tank, preventing any cold shower surprises. Other advanced features include scheduling around peak electricity rates, an energy usage tracker to manage consumption without sacrificing comfort and five operating modes to balance between energy usage and hot water availability.

Plumbers can access detailed system diagnostics through Rheem’s Contractor App, which shortens service visits and improves credibility in the field. The ProTerra has all serviceable components on the front of the unit, which also saves plumbers valuable time on a jobsite. Another benefit to plumbers is the unit’s zero clearance requirement on the sides. This makes earthquakes straps easy to install, providing an extra benefit in California where earthquake straps are code.

“Our ProTerra hybrid water heater is not only the most efficient water heater available, it is also NEEA Tier 4 certified and comes with CTA 2045 adaptor with full Demand Response capability out of the box,” said Scott Cohen, Senior Manager, Rheem. “This level of product efficiency is Rheem’s ongoing priority when developing new innovations and supports the company’s “Greater Degree of Good” sustainability initiative which includes reducing GHG emissions by 50 percent.”

The ProTerra qualifies for the highest level of energy rebates, will save homeowners up to nearly $500 in annual energy costs[1] and will pay for itself within two years[2]. For more information on utility rebates, ask your local utility provider and visit www.rheem.com/hybrid.

[1]Based on comparison against the estimated annual operating cost of a standard electric water heater of like capacity manufactured prior to 2015 under NAECA II which is likely being replaced.

[2]Based on purchase price and energy cost savings of a 50-gallon Hybrid Electric Water Heater with 3.55 UEF (3.50 EF) over a 50-gallon standard residential electric water heater with a 0.93 UEF (0.95 EF).

Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator. These circulators are available with cast iron or Read more

Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

These circulators are available with cast iron or NSF/ANSI 61 & 372 certified stainless steel volutes, so they are ideal for closed-loop heating systems as well as domestic hot water recirculation systems. Both circulators also offer a convenient, rotatable control box cover for a professional look, no matter the orientation of the installed circulator.

The 0034e features an easy-to-use dial with five operating modes, including constant pressure, fixed speed, Taco’s exclusive activeADAPT™ self-adjusting proportional pressure, and 0-10V capability. The 0034ePlus adds proportional pressure and more constant pressure settings as well as a digital display with real-time feedback, including watts, GPM, feet of head, and RPM. Both circulators are dual-voltage 115V/230V.

Both new circulators come with exclusive features that make Taco’s ECM high-efficiency circulators so easy to use, including SureStart® automatic unblocking and air purging, BIO Barrier® black iron oxide protection, dual electrical knockouts, six-inch stranded leads, recessed flange nut-grabbers and double insulation so no ground wire is needed.

For more information, visit www.TacoComfort.com

Mickelson Plumbing & Heating, Missoula, Montana, specializes in plumbing, HVAC and boiler service, and high-efficiency systems. Starting his own business out of necessity, or perhaps the illusion of it, Andy Mickelson (@mick_plumb) launched Mickelson Plumbing & Heating New Year’s Day, 2011. I guess you could say it’s all part of Mickelson’s fabric and mental make-up—there Read more

Mickelson Plumbing & Heating, Missoula, Montana, specializes in plumbing, HVAC and boiler service, and high-efficiency systems.

Starting his own business out of necessity, or perhaps the illusion of it, Andy Mickelson (@mick_plumb) launched Mickelson Plumbing & Heating New Year’s Day, 2011. I guess you could say it’s all part of Mickelson’s fabric and mental make-up—there is no end result other than success. “I am a terrible loser; I hate not winning daily,” says Mickelson.

Turning the clock back to where it all began, Mickelson was eight years old when he got his taste of real hard work, helping out his father, a remodeling contractor. “It was easy to have my brothers and me helping out, and at that time, we were eager to get dirty and learn how to build things, and THAT has never stopped,” says Mickelson.

Soaking up knowledge whenever he had the chance, Mickelson has had many great mentors in his first shop, and the UA produces an incredible brotherhood of knowledgeable folks. “Dick Darne was one of the Journeyman that I learned the most from; he had a hip replacement, and a few weeks later I began my service career, carrying his tool bag and being his hands in the field when he couldn’t. All I had to do was listen to directions and retain the methods of his madness. The troubleshooting tactics I learned in a roundabout way were invaluable.”

Today’s Landscape

Nearly 10 years after venturing on his own, who could’ve ever foreseen the situation we are faced with today? “The first quarter was one of the best we’ve ever seen, but April produced only 68% of the average business produced in the first three months of the year,” says Mickelson.

Thankfully, Montana has seen fewer COVID-19 cases than the rest of the country, and the state has re-opened for business. But that’s not to say Mickelson isn’t taking the necessary PPE precautions, and Mickelson is screening all customers at this time. “For the most part, we are not taking on work that can be postponed.”

In general, needless to say, Mickelson loves what he does—creating solutions for his customers. “Service work allows me to do that several times a day. It’s a good thing.”

But thinking of going out on your own? A heavily-involved Boy Scout leader, Mickelson suggests taking its motto to heart—Be Prepared. “Plan, Plan, Plan. There are fantastic resources available to help people prepare to start a business. USE THEM! Also, you have to answer the simple question, am I ready to be a business owner first and a plumber second? If yes, then proceed. If no, rethink the approach get your mind right. Businesses hire good plumbers, not the other way around.”

And those who are thinking of getting into the trades? “Do it, unless you have a better plan that actually pays,” says Mickelson, but he stresses that we need to kill the stigma that the trades are all about hard work. Concerning to Mickelson, those who discourage others from entertaining the idea of becoming a tradesman based on the work being too tough or man’s work. “Anyone who indulges in this tactic is merely afraid of their own deficiencies and nervous about being replaced by someone who may work smarter or harder.”

Sure, there are aspects that are hard, continues Mickelson, but with continued education and exerting oneself, reaching a higher level of employment in the trades is a real possibility. Good work ethics and attitude are noticed—one may not hear about it—but it doesn’t go unnoticed. And, share the knowledge others have shared with you. “I have always found that it is far easier to share knowledge with a willing listener than it is to intentionally with hold it,” says Mickelson.

Mickelson’s career has afforded him a good life with his wife and two kids. “Family time is my favorite. Second would be exercising my 2nd Amendment rights. Both of which usually occur outdoors.”

Yet balancing work/family life is a careful endeavor for Mickelson. “It’s really easy for family to take a back seat and be lost in the hustle. I traditionally try to make sure that work is done during the day and that my ‘Night Shift’ doesn’t start until everyone has begun to wind down for the night. All in all, business has taught me to use my time efficiently, and set priorities, Family, friends, money, seems to be a good flow.

All in all, waking up every day is a blessing for Mickelson. “I’ve told my kids for years that they are the only person who can make their day a bad day, so go into battle and aim for a great day, and worst-case scenario it’ll be OK.”

Ductwork Learnings on HVAC and Aging in Place The term “aging in place” refers to homeowners’ ability to stay in their home as they age. But what’s good for a homeowner, may not be good for a home’s ductwork system. As homes built during the housing boom of the late 1990s and early 2000s age Read more

Ductwork Learnings on HVAC and Aging in Place

The term “aging in place” refers to homeowners’ ability to stay in their home as they age. But what’s good for a homeowner, may not be good for a home’s ductwork system. As homes built during the housing boom of the late 1990s and early 2000s age, many of these homes’ ductwork systems – particularly in areas such as the deep south – are beginning to show their age.

While HVAC contractors understand the benefits of replacing aging, less efficient HVAC equipment, what about the unseen parts of the comfort system? Even the highest performing, most energy efficient system will not deliver optimal performance if the invisible network of ducts that distribute air to every room in a home are damaged, leaky, or poorly connected.

Aging ductwork is a key concern in many housing markets that experienced robust growth during the housing boom – Southern Florida, Phoenix and Las Vegas, for example. Ductwork in many of these warm region homes is located in the unconditioned attic space, where it is out of sight and not subject to routine maintenance.

The integrity of a home’s ductwork in unconditioned spaces can have a big impact on comfort, energy, and efficiency. Offering duct inspections and retrofits can help contractors optimize their customers’ comfort while generating an additional source of revenue for the business.

Owens Corning recently piloted a duct retrofit service with five HVAC contractors in Florida. The objective was to understand homeowners’ interest in ductwork -and evaluate conditions in aging homes. The HVAC ductwork inspection evaluated key ductwork areas, with a focus on helping stop the spread of airborne pollutants and unwanted noise while improving home comfort and efficiency:

Ductwork inspections reviewed:

- Duct insulation integrity

- Interior duct condition

- Exterior duct condition

- Sealing around duct joints

- Evaluation of output efficiency

Contractors in the pilot found that a home’s ductwork is an overlooked opportunity to add comfort and support homeowners in creating comfortable environments. Few homeowners are aware of the role their home’s ductwork plays in facilitating comfort, air flow and the spread of airborne pollutants. Contractors also found that speaking with customers about their home’s ductwork, conducting a duct inspection, determining if the duct is sized properly, and explaining the benefits of a duct retrofit helped generate new business opportunities.

Pilot participants found that a good place to start the conversation with homeowners is by reviewing a checklist of signs suggesting duct problems. These signs may include:

- Musty smell

- Excessive dust

- Mold/mildew or visible “dirt” around vents

- Condensation on (or near) AC unit cooling coils

- Frequent cycling

- Hot or cold spots

- Visible ductwork damage

While many homeowners take great pride in having the most energy efficient cooling equipment, they will not enjoy the benefits of their investment if their ducts are leaking. In fact, the typical house loses up to 30% of the air in ducts due to leaks and holes in ductwork. Today’s HVAC equipment is more energy efficient than ever, standing up to today’s vigorous code environment and weather that seems to keep getting warmer. But as American homes age and energy codes are stricter, the ductwork distributing air is not keeping pace.

To learn more about Owens Corning’s air distribution services and how duct retrofit can support your business and the homeowners you serve, contact Duct Retrofit Program Business Development Leader Dave Pawlicki at dave.pawlicki@owenscorning.com

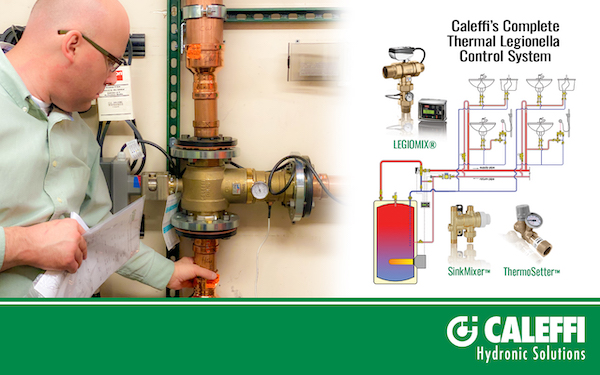

The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Read more

The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Legionella which can proliferate to dangerous concentrations.

Experienced water maintenance managers know susceptible systems should be flushed before reusing. Important considerations should not be overlooked such as ensuring all service lines are purged and dead legs drained.

Several factors determine if the system equipment requires treatment such as how long a system is left idle, the temperature of the stagnated water and condition of the internal surfaces. This is so bacteria that are resistant to simple purging/draining and have become resident in biofilm can be addressed. Common methods include thermal treatment or treating with chemicals such as chlorine, chlorinated gas and chlorine dioxide.

A significant benefit of thermal treatment is that it’s a proven, cost-effective method for bacteria management on an ongoing basis in the hot side of the plumbing system. The cold side doesn’t typically require ongoing treatment unless water remains stagnated for extended periods within the temperature range that Legionella grows which is 68°F to 122°F.

Thermal treatment requires little additional maintenance compared to chemical treatment. Also, common plumbing equipment such as seals, gaskets and polymer components are not exposed to potentially incompatible life-shortening chemicals.

Residual chemicals in the water can also be a human health concern if acceptable concentration values are exceeded. In contrast, most common plumbing materials can withstand, without effect, thermal shock temperatures such as 160°F.

Thermal treatment consists of periodically circulating elevated water temperature such as 160°F through the entire system for a specific and measured period of time, thereby killing harmful bacteria and restoring the water to a safe and usable condition. During this period it is important to ensure all point-of-use fixtures are either disabled for access or equipped with anti-scald devices. An example is the Caleffi scald-protection valve SinkMixerTM — an innovative, easy to install valve for under-sink applications.

Often the most difficult portions of the hot water side to circulate sufficiently through is the recirculation return risers. This because they are sized and balanced to a relatively low flow rate such as 0.5 GPM. The Caleffi ThermoSetterTM thermal balancing valve automatically responds when it senses high temperature water by fully opening an internal by-pass, thereby allowing a sufficient return riser flushing during treatment. It then automatically returns to standard operation state when water temperature decreases to normal.

If a building is equipped with a Caleffi LEGIOMIX digital mixing valve, it will enjoy highly accurate mixed water temperature 24/7. The LEGIOMIX has industry-unique, calendar- based automatic thermal disinfection programs. For thermal monitoring, it has data logging capabilities and can connect to a building automation system for remote monitoring and access.

LEGIOMIX combined with SinkMixer anti-scald valves and ThermoSetter recirculation balancing valves offer an innovative total thermal solution for control of safe and sanitary domestic hot water.