A Rolls Royce with a Veto Pro Pac tool bag in the trunk. Now that’s pretty drippy. For Moe Hirsch, Moes Consulting and Mechanical Services, Rockland County, N.Y., his bucket list item is a good representative mix of work and swaggy. Hirsch basically started off in the trades when he joined his cousins, who were plumbers Read more

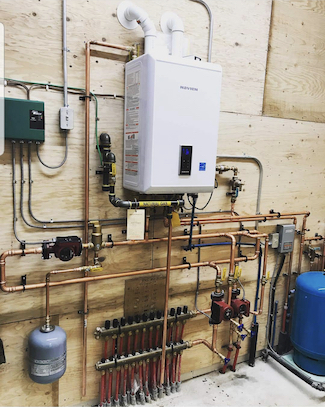

hydronics

A Rolls Royce with a Veto Pro Pac tool bag in the trunk. Now that’s pretty drippy. For Moe Hirsch, Moes Consulting and Mechanical Services, Rockland County, N.Y., his bucket list item is a good representative mix of work and swaggy.

A Rolls Royce with a Veto Pro Pac tool bag in the trunk. Now that’s pretty drippy. For Moe Hirsch, Moes Consulting and Mechanical Services, Rockland County, N.Y., his bucket list item is a good representative mix of work and swaggy.

Hirsch basically started off in the trades when he joined his cousins, who were plumbers, for a few days and he immediately loved the excitement. Eventually, when things began to slow down, “I went out on my own using the heating knowledge I had learned. I had the mentality that if someone was going to figure it out, it might as well be me.”

From there, Hirsch grew into a plumbing, heating and cooling company, and two years ago began distributing and installing Cummins generators. Currently, the company focuses on the mechanical trades but offers property services to its clients as well.

Hirsch says he’s learned a lot from so many that narrowing it down would be impossible to credit everyone. Having said that, “The trade leaders for me were Dan Holohan, Mark Eatherton, Bob Hot Rod Rohr and John Siegenthaler. In the business world, Grant Cardone and Brandon Dawson have showed me what my true potential is. You really can learn something from everyone,” says Hirsch.

In addition to meeting and helping so many people, another rewarding aspect of the trades is that it can be very profitable. And while you can be in the trenches working hands-on, says Hirsch, you can use your skills to be a great manager, assistant or other asset to a company. “It’s not all wrenching knowledge. Business to me is 33% knowing your trade, 33% knowing business management, fact finding and sales, and the other 33% is just being a genuine, kind person.”

How can the PHVAC industry do a better job attracting people to the trades? Hirsch, you could say, practices what he preaches. As he prepares for every job, Hirsch makes sure he has his MacBook, latest smart phone, his personal CO detector and his loaded Veto bag, and says, “Make trades cool again; show kids the cool stuff. If they’re into muscle cars show them a tradesman driving his mustang to work. If they’re techy, show them someone performing a diagnostic using a computer.”

Moreover, social media, whose influence on young people can’t be denied, has opened many doors for tradespeople. “Social media is a free outlet to showcase your work—you can share your work, learn from others and link up with locals. Plus, social media can make the sale easier. The client feels they know you and is more willing put their trust in you,” says Hirsch.

Moreover, social media, whose influence on young people can’t be denied, has opened many doors for tradespeople. “Social media is a free outlet to showcase your work—you can share your work, learn from others and link up with locals. Plus, social media can make the sale easier. The client feels they know you and is more willing put their trust in you,” says Hirsch.

As far as balancing work/leisure time, “I don’t balance them,” says Hirsch. “I try to do both to the max.” And that includes spending time with his wife and kids, training his new Golden Retriever, Marshmallow, and, of course, bumping into clients and seeing their happiness.

Milwaukee Valve has announced the retirement of President and CEO Rick Giannini, effective January 20, 2023. John Labellarte, the company’s current COO, will succeed Giannini in leading the commercial, industrial and marine valve manufacturer. Giannini joined Milwaukee Valve in 1998 and successfully guided the business through challenging market conditions. His leadership transformed Milwaukee Valve into Read more

John Lebellarte

Milwaukee Valve has announced the retirement of President and CEO Rick Giannini, effective January 20, 2023. John Labellarte, the company’s current COO, will succeed Giannini in leading the commercial, industrial and marine valve manufacturer.

Giannini joined Milwaukee Valve in 1998 and successfully guided the business through challenging market conditions. His leadership transformed Milwaukee Valve into a service leader and global manufacturer. He guided the transformation of the sales organization, reinvested in manufacturing processes and equipment, and assembled the company’s overseas manufacturing operations. Giannini greatly expanded the development and growth of Milwaukee Valve’s product offering and presence in the Navy Marine market.

Giannini also developed and maintained the management team which will continue to lead the company. He dedicated time and energy to industry-leading organizations, serving as Chairman of the Aircraft Carrier Industrial Base Coalition (ACIBC) since its inception in 2004. He also sat on The American Supply Association’s (ASA) Industrial Piping Division Steering Committee and served on ASA’s Board of Directors.

New president and COO John Labellarte started with Milwaukee Valve in 1999 as General Manager. He was promoted to Vice President and COO in 2006. During his tenure, Labellarte has been instrumental in driving the company’s global manufacturing initiatives, strategic planning, product development and operational performance. His focus on continual improvement and the utilization and development of new technologies will continue to build brand value and value proposition for the company. Prior to joining Milwaukee Valve, Labellarte worked for 12 years with the Marpac & McCANNA Valve companies, serving in operations and management roles. He is extremely qualified to lead Milwaukee Valve, with 35 years of executive and operations management experience in the valve industry.

In its 121st year of business, Milwaukee Valve Company is internationally recognized for state-of-the-art manufacturing facilities and innovative new products covering a wide range of commercial and industrial applications.

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once Read more

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

While he’s not busy with his day job working on hydronic heating systems, commercial and residential plumbing, backflow prevention and gas work, Chris Massaro (@nwo_plumber) loves playing guitar and recording music. Admiring the recent tattoo to commemorate his daughter’s birth, “I was in a bunch of bands throughout high school and recorded an album once. I don’t get around to it as much as I used to or like to, but I’m definitely making more time for that now,” says Massaro, owner/lead tech at Aqua North Plumbing and Heating Ltd., Thunder Bay, Ontario, Canada.

I take that back. Massaro also enjoys hanging out with friends and family, golfing and mountain biking. And, he definitely needs to get that grill time in—grill, smoke, BBQ. “Sometimes in that order, in one cook. Most of the time I do use the smoker though. I’ve been on a pulled pork kick lately. My favorite is some nice pork shoulders on the Traeger. It’s the ultimate dad activity, in my opinion,” says Massaro.

The work\life balance has been a struggle for Massaro; he realized one day that when you are running your own small business sometimes there isn’t a balance. You have to make the time and prioritize it. “Do what’s important to you and make time for the people and activities you love. And most importantly, take care of yourself! Because you’re worth it. Time stands still for no one so spend it wisely,” says Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

And that’s why staying physically fit and active is important to Massaro. “I’m always lifting, bending, up and down the stairs all day so it’s helpful to have a training regimen that supports that. And, it really helps to keep me in mental shape as well,” say Massaro.

Even more important is eating right, says Massaro. “We use a lot of energy in a day in the trades so we have to keep that fire fed. All of this allows me to stay energized all day and still have plenty of gas in the tank when I get home for family time,” continues Massaro.

Massaro’s foray into the trades started when he starting working for the family business as a plumbing apprentice at the age of 13. “Made best friends with my shovel and we went to work. Thankfully, I graduated from digging trenches and went on to start really learning about the ins and outs of the trade,” recalls Massaro.

Over the next few years, Massaro spent most days plumbing residential systems with a few commercial jobs sprinkled in here and there while working for my father. “It was nice to be doing a bit of everything and not just strictly one area of the trade, which I felt was important to be a well-rounded tech.

Once Massaro had a few years under his belt, he did a lot of remote northern work for fly-in communities. “Those big jobs we did up there really sharpened my time and material management skills,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

In addition, the high school Massaro attended offered a cooperative education program where he was able to gain work experience hours toward his apprenticeship if he chose to stick with plumbing. “I would go to regular classes for the morning periods then co-op at Aqua North in the afternoon,” says Massaro.

As a side note, Massaro says that if your local high school offers a cooperative education program, he highly recommends getting involved. “It’s a really pressure-free way to get your feet wet in whatever trades the school offers,” says Massaro. “I always try to take on one co-op student per year and leave them with a positive experience in the trade. I feel that’s the best way for kids to feel out what they want to do. And, don’t be afraid to ask questions!”

Next, after getting all of his trade school and work hours complete, Massaro then wrote his exam for his certificate of qualification in plumbing. Shortly thereafter, Massaro bought the family business, and the rest is history.

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

As fourth-generation plumber, Massaro has had some great mentors in his career, with plenty of help and guidance from his father and grandfather in learning new and old ways of plumbing. “If my great grandfather was around then I’m sure he would have some real old school stuff to show me.”

And while Massaro doesn’t consider himself a role model, he’s always willing and ready to help others to do their best at work, and life in general. “I’ve learned a lot over the years and sharing the experiences and knowledge with up-and-coming tradespeople is paramount,” says Massaro.

For Massaro, he loves building something from nothing and executing the job. “Sometimes just sitting back after the job is done and being like ‘damn we really did that.’”

Perception Change

The perception of the industry needs to change, says Massaro. “I think the wheels are turning on that as we speak but we’ve got a long way to go.”

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Social media is that vehicle for the instrument of change as it’s an easy way to showcase contractor work, and connect with other professionals. “There’s a solid amount of tradespeople out there doing an amazing job. If we can show people that there’s more to plumbing than just plunging toilets, fixing leaks, and back-breaking work, then I think that’s a win,” says Massaro.

Whether it’s new and better tools, techniques, business knowledge, etc., Massaro has learned so much on social media. “It’s awesome that we can connect with people and have such a great community sharing tricks of the trade, meet-ups or even debate if it’s tape then dope—which it is—or dope then tape,” says Massaro.

In the end, as Massaro sets his sights on his career and further enriching his life, a good bucket list item to check off would be getting a recreational pilot’s license. “Always wanted to get into aviation in some way.”

The sky’s the limit.

By Aaron Stotko When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high. That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion Read more

By Aaron Stotko

When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high.

That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion connections to be the ideal system, due to its durability and ease of installation in addition to the job-site productivity, safety and, best of all, profitability potential it provided.

And City Wide Mechanical isn’t alone in their findings. Many mechanical contractors are discovering the benefits of PEX-a pipe and F1960 connections as the preferred alternative to copper, iron, and steel, which have dominated the mechanical piping industry for decades.

Benefits of PEX-a

PEX is an acronym for crosslinked polyethylene. It has been used in North America since the mid-1980s, starting with radiant floor heating systems, then moving into plumbing and, eventually, to hydronic hot-water heating and chilled-water applications.

PEX can be manufactured via three different processes, which create products with varying crosslinking percentages that allow for different characteristics. PEX-a is the most durable, flexible, and resilient with crosslinking around 85%. PEX-b is a stiffer piping product with crosslinking around 65% to 70%, and PEX-c features crosslinking around 70% to 75%.

ASHRAE Headquarters Grand Opening Fall 2021, photos by Devin Abellon

One major benefit of the higher crosslinking in PEX-a is its extreme flexibility along with its thermal and shape memory. The flexibility of PEX-a eliminates most connections in smaller-diameter piping, saving time and money with up to half the connections required in rigid metal piping systems. To make a change in direction, the installer simply bends the pipe instead of having to stop and make a fitting. There are also bend supports available that help hold a bend securely in place.

The thermal memory of PEX-a provides kink repairability with a simple shot of heat from a heat gun. This eliminates the need to add in a coupling if a kink ever occurs in the pipe. (It is important to note that kink repairability is not possible with PEX-b or PEX-c pipe.)

The shape memory of PEX-a allows the pipe to expand and contract back down to its original shape. This makes it extremely resilient in freezing conditions and also provides for the fastest, easiest, most reliable PEX-a fitting system — F1960 expansions.

Expansion fittings require one simple tool to expand the pipe and an expansion ring before inserting a fitting. As the pipe and expansion ring naturally shrink back to their original shape, it creates a strong, durable connection that holds tight and can never be dry-fit. (Note: It is not recommended to expand PEX-b or PEX-c pipe due to microcracking that can occur.)

The innovative expansion fitting method eliminates torches, glues, and solder from a job site for greater worker safety. Plus, the system is extremely easy for installers to learn, helping get new crews up to speed quickly.

Speaking of job-site safety, PEX is also much lighter in weight compared with metal systems. For example, a 300-foot coil of 1/2-inch PEX weighs about 18 pounds, whereas the same amount of copper pipe weighs around 85 pounds. The lighter weight of PEX makes it safer and easier for installers to move around a job site and also eliminates the need for heavy-lifting equipment.

PEX-a also has a long-term advantage over copper when it comes to performance longevity. It is a static system, meaning its internal surfaces — which are three times smoother than copper — will not pit, scale, or corrode. That means its performance will remain the same from day one through decades of use.

Finally, because it is not a traded commodity, PEX-a holds a relatively stable material cost. This makes bidding a project much more consistent and reliable.

Application Details and Installation Tips

PEX-a is regulated by the ASTM F876 standard, which denotes temperature and pressure ratings of 200°F at 80 psi (pounds per square inch), 180°F at 100 psi, and 73.4°F at 160 psi. These values are well within the range of operation for most hydronic systems, including chilled beams, fan coil units, baseboards, radiators, hydronic VAV (variable-air volume) reheat coils, and radiant manifolds.

Because PEX is oxygen-permeable, it is important to use a pipe with an oxygen barrier that limits oxygen diffusion to levels below DIN 4726. This will protect the metallic components in the mechanical piping system, such as valves, strainers, and pump volutes, from corrosion.

The pipe is manufactured in sizes from 5/16 inch up to 4 inches and features a copper tube size (CTS) outside diameter. This means all the off-the-shelf components used in a copper hydronic piping system — hangers, supports, and insulation — can be the same.

For horizontal piping, the industry offers PEX-a Pipe Support — a galvanized-steel channel that is 9 feet in length and available in PEX pipe sizes from ½ inch to 3½ inches. This solution enables hanger spacing similar to copper pipe and helps control the natural expansion and contraction of the pipe as it heats and cools.

Because PEX-a expands at 1.1 inches per 100 feet per 10°F Delta T (which is 10 times that of copper), installing anchors every 65 feet and using PEX-a Pipe Supports allows PEX-a to function much like a copper system. In fact, different installation methods have a different effect on the overall net expansion rate.

With a strut-and-clamp system, using PEX-a Pipe Supports and anchoring with fixed points reduces the expansion rate of PEX-a to 0.08 inches per 100 feet per 10°F Delta T (a rate less than copper). And a loop-and-clevis system can reduce the rate to 0.12 inches per 100 feet per 10°F Delta T.

If you’d like to learn more about PEX-a piping systems, visit the Plastics Pipe Institute at plasticpipe.org or the Plastic Pipe and Fittings Association at ppfahome.org.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Expansion tanks are a vital safety component in plumbing and hydronic systems. In the next edition of Coffee with Caleffi™, legend Bob “Hot Rod” Rohr joins Cody Mack to expand your knowledge of these versatile tanks. They will discuss function, sizing and how to avoid common failures. Attendees will also learn about proper placement, multiple-tank Read more

Expansion tanks are a vital safety component in plumbing and hydronic systems. In the next edition of Coffee with Caleffi™, legend Bob “Hot Rod” Rohr joins Cody Mack to expand your knowledge of these versatile tanks. They will discuss function, sizing and how to avoid common failures. Attendees will also learn about proper placement, multiple-tank applications, vessel linings and other best practices. This edition of Coffee with Caleffi will be on Thursday, Aug. 18 from 12 noon – 1:00 p.m. CDT.

Rohr is a 2020-2022 Carlson-Holohan Industry Award of Excellence honoree, he travels from sea to shining sea for Caleffi North America, sharing his 40+ years’ of experience as a plumbing, radiant heat and renewable energy contractor. He is a regular contributor to industry magazines where Hot Rod brings his rubber-to-the-road experiences to life.

Mack has nearly 20 years’ experience as installation contractor, service technician, application engineer, training manager and now product manager for Caleffi. Our audience will appreciate his thoughtful yet humorous content delivery combined with his practical, common sense product approach.

The monthly educational webinars are free and are intended for engineers, contractors, designers and wholesalers. A Certificate of Attendance is emailed to attendees following the event for continuing education audits.

Please visit our website at www.caleffi.us for schedule details and registration.