The Grand Opening of Rinnai’s RAM Lakes Facility in Griffin, Ga., featured the first non-condensing tankless—the first of many salable units— manufactured here in the states. At approximately 6:15 am on a crisp Tuesday morning, Rinnai America Corporation made history in the United States, and all of North America. At its new 300,000-sq.-ft RAM (Rinnai Read more

Plumbing

The Grand Opening of Rinnai’s RAM Lakes Facility in Griffin, Ga., featured the first non-condensing tankless—the first of many salable units— manufactured here in the states.

President, Rinnai America Corporation, Frank Windsor puts his John Hancock on the first unit manufactured at the RAM Lakes facility in Griffin, Ga.

At approximately 6:15 am on a crisp Tuesday morning, Rinnai America Corporation made history in the United States, and all of North America. At its new 300,000-sq.-ft RAM (Rinnai America Manufacturing) Lakes facility in Griffin, Ga., the first—of many non-condensing tankless water heaters—rolled off the line. On April 21, 2022, the Griffin facility completed the production of its first tankless water heater, a unit of the highly anticipated RE Series, the first and only non-condensing unit with a built-in pump and SmartCirc intelligent recirculation technology.

“This is a significant milestone for our company and corporation. We are here to celebrate not only becoming the first major tankless manufacturer in the North American market to invest in domestic manufacturing,” said Frank Windsor, President, Rinnai America Corporation. “But we are also launching a brand-new product here today, which will become a really compelling product we bring to market.”

On April 21, 2022, Rinnai held a festive Grand Opening at its RAM Lakes facility.

“This morning, the first RE Series tankless water heater came off the end of the line,” said Shelley Kiley, Vice President of Operations. “The day has arrived that we are going to produce our first salable RE Series tankless hot water heater and we are so excited. Over the last two years, it’s been a challenge for the entire team. They worked tirelessly through a lot of challenges, obviously covid, global supply chain issues, escalation of pricing of materials for the construction of this and I would say that the whole team is really proud that they came within 4% of budget and only six weeks of delay on the entire project from start to finish,” said Kiley.

Throughout the new facility, Rinnai definitely puts its money where its mouth is as you’ll find fully operational tankless units humming beautifully throughout, like this SENSEI RSC199iN.

In 2017, the global organization recognized the significant potential for this market and made the decision to invest in Rinnai America to become a growth vehicle for the corporation. According to Windsor, this has been a substantial investment over the last three or four years—a new corporate headquarters in Peachtree City, which was an $18 million dollar investment, a $10 million investment in our new world class innovation center attached to our headquarters in Peachtree City, along with this manufacturing and distribution center, which was a $70 million investment.

Perhaps supply chain issues have been alleviated with manufacturing in the states. Here, in the 140,000-sq.-ft. distribution center, the inventory is aplenty with tankless units produced at the RAM Lakes facility.

Over the last four years, the company has invested $100 million to show its commitment to the North American market. “In 2020, amidst all of the chaos associated with the pandemic, our company chose to move forward and invest, break ground on the facility we are standing in today. I’m very proud of the hard work and dedication our team has put forth in this initiative, which is critical for our organization’s future growth and success,” said Windsor.

With a goal of 400 units manufactured per line, at the time of the Grand Opening celebration, one line was up and running with a projected three lines running by summer. In addition, the RAM Lakes facility has already employed more than a hundred of the new local top talent with a projected few hundred additional jobs to be added by the end of the year.

Exporting tankless. What a concept. How cool is that? “It is cool. We will be shipping them to Mexico and shipping them throughout Latin America. We have a fast-growing Latin American business. It’s fun to be able to make product here in the U.S. and ship to other parts of the world,” said Windsor.

Tanika Peoples, Senior Human Resources Generalist, talks about Rinnai’s core values at the new facility.

Moreover, with all of the supply chain issues and complexities, having manufacturing here in the states alleviated some of the hassle. “This will have a huge impact on our supply chain. No. 1, we will be making the product right here in closer to our customer, and No. 2, we don’t have to rely on containers and supplies coming out of China. We are purchasing many of the parts right here in the U.S. or we’re purchasing it from our company in Japan. That really simplifies the process; it gets the product much closer to us. It’s also building the competency for our team to be able to innovate going forward.”

** Rinnai is a $3.2 billion company that is seen as one of the leading gas appliance manufacturers in the world. Rinnai is a market leader in Japan, Asia, Australia, New Zealand, with businesses also in Italy and the UK. For more than 100 years, Rinnai has developed high-quality products to heat water and homes. However, within the last few years, the company has looked towards new expansion opportunities, including investing in new markets to sustain innovation as well as operationalizing manufacturing and production to meet need. The North American market was quickly identified as one of the greatest growth vehicles for the company. Rinnai entered North America in 1974 in Southern California, moved to LaGrange, Ga., and recently its headquarters in Peachtree City, Ga.

The plumbing industry has grown steadily by 2.1% since 2017. This makes it one of the most actively growing industries in the US. By January 2022, there were 129,517 plumbing businesses operating in the US, which is likely to increase by 2023. However, running a plumbing business can be as challenging as any other establishment Read more

The plumbing industry has grown steadily by 2.1% since 2017. This makes it one of the most actively growing industries in the US. By January 2022, there were 129,517 plumbing businesses operating in the US, which is likely to increase by 2023. However, running a plumbing business can be as challenging as any other establishment. Although it has peculiar problems, some general business solutions can be applied. Here are some common problems to be aware of.

Difficulty in customer retention

Like any other entity, repeat business for plumbing works often depends on client satisfaction. When the customer is dissatisfied with the work done, the likelihood of hiring another plumbing company is higher. This makes customer retention a huge challenge for plumbing businesses. According to an IBIS World survey on this issue, three out of five customers are likely to try another plumber. It further reported that this often happens when the customer or client is unhappy with a previous job.

Indeed, it is a very competitive industry with high customer expectations. So, if you’re struggling with customer retention, perhaps, it will be worthwhile to assess your services. For example, do you frequently attract people with unbelievable discounts and offers? If that is the case, you may rather be putting potential clients off. Those unbelievable discounts may be interpreted as sub-standard service. Furthermore, do you have hidden charges only known to the customer after the job is done? Once again, if you answered in the affirmative, it may be time to review that strategy. Many things often account for why your plumbing business cannot retain customers. However, when you identify those loopholes, things could turn around for the better.

Problems with pay systems

A fundbox.com survey stated that 50% of plumbers face cash flow problems. This, however, applies mostly to licensed freelance plumbers as those who work as employees for companies often do not experience this problem. It is even worse for plumbing businesses with multiple branches in different locations. It takes a lot of effective management skills to handle so many workers in different locations. Without it, your business may struggle with making timely payments, among other things. You will need an effective payroll system to avoid any delays. Moreover, because many plumbing companies pay their workers on a commission basis, this is necessary.

Non-existent or poor target marketing

First of all, it’s already been established that the plumbing sector is highly competitive. For whatever reason, it’s been discovered that some plumbing businesses fail to work on effective marketing. The truth here is that people do not seek information about plumbing businesses until they’re in dire need of one. However, if your target marketing is done right, you will have clients calling for routine plumbing checks.

Target marketing involves studying the demographic of your business’ location. If it is mainly a residential area, your marketing can focus on homeowners living in really old properties. The reason is that old houses often have hidden plumbing issues usually discovered when things get out of hand. By positioning your business as the go-to plumber, you increase your business’s chances of receiving more calls for old home jobs.

With proper planning and effective strategies, most of these problems can be avoided in your plumbing business. No business operates without glitches. However, what you do to avoid or minimize them can influence your success.

Grenada, Miss. — Milwaukee Tool is excited to announce construction on their newest facility in Mississippi. Located in Grenada County, Mississippi, Milwaukee’s latest expansion will accommodate the company’s growing power tool accessories and power tool business, and will also serve as a centralized repair facility. The new location will create more than 800 new jobs, and Read more

Grenada, Miss. — Milwaukee Tool is excited to announce construction on their newest facility in Mississippi. Located in Grenada County, Mississippi, Milwaukee’s latest expansion will accommodate the company’s growing power tool accessories and power tool business, and will also serve as a centralized repair facility. The new location will create more than 800 new jobs, and is planned to open in mid-2023.

“We’re thrilled to, once again, expand our footprint in the state of Mississippi, where we’ve been able to recruit some of the best talent in the country,” said Steve Richman, Milwaukee Tool Group President. “Our success is the result of our talented people and the culture we’ve created; it is unparalleled in the industry. We are committed to investing in new talent, and the right opportunities to continue meeting the needs of our distributor and user partners with the speed and agility that defines who we are as a company.”

Milwaukee® is investing more than $60 million into advanced technology and manufacturing equipment at their new 563,000-square-foot Grenada location. The facility will house critical accessory manufacturing capabilities, and will join the company’s other service hub in Greenwood, IN, as one of Milwaukee Tool’s main axis points for service operations.

Milwaukee Tool, which employs more than 10,000 people in the U.S., has continually expanded their footprint domestically and globally as their company experiences incredible double-digit growth. In Mississippi, the company has invested more than $209 million in domestic expansion projects over the last 5 years and employs 4,400 people.

More About Milwaukee’s Growth & U.S. Investments

Milwaukee Tool is a global company with manufacturing, distribution, and operations presences across North America, South America, Europe, Asia, and Australia. The company has designed, engineered, and manufactured products in the United States for nearly 100 years.

In the last year, Milwaukee® has invested $216 million in domestic expansion projects. In addition to this new Grenada location, the company’s other domestic presences include Greenwood, Olive Branch, Clinton, and Jackson, MS, as well as in Brookfield, Menomonee Falls, Milwaukee, West Bend, Mukwonago, and Sun Prairie, Wis., Cookeville, Tenn., Chicago, Ill., and Greenwood, Ind.

Flagship showroom in Fulton Market District highlights Sloan’s full suite of aesthetic, hygienic commercial restroom products. Chicago—On a dreary Tuesday morning in early May, Sloan sparkled by holding a ribbon-cutting ceremony to celebrate the opening of its flagship showroom and office space in the Fulton Market District. The flagship showroom highlights Sloan’s full suite of aesthetic Read more

Taking part in the ribbon cutting ceremony for the new space were Graham Allen and Kirk Allen, Sloan co-presidents and CEOs and fourth generation descendants of company founder William Elvis Sloan.

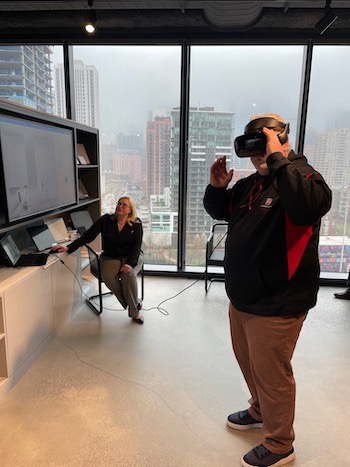

The Hub’s John Mesenbrink took part in some AR technology from the showroom.

Located on the building’s 10th floor, Sloan’s showroom space represents a return to the company’s origins, as Sloan was initially founded on nearby Jackson Boulevard prior to moving to its current Franklin Park headquarters in 1975. The new building features an office space and showroom, while Sloan’s manufacturing and corporate headquarters remains in Franklin Park.

The showroom features a wide range of Sloan products and innovations, including flushometers.

The showroom features a wide range of Sloan products and innovations, including sensor-activated faucets.

Webstone, a brand of NIBCO, announces new press × NPT products including ball valves with reversible handles, elbows, and couplings. Choose between MIP or FIP ends to easily transition from iron to copper or appliances to system piping. Also available is the new press ball valve with bleeder and reversible handle and large Pro-Pal® Union Read more

Webstone, a brand of NIBCO, announces new press × NPT products including ball valves with reversible handles, elbows, and couplings. Choose between MIP or FIP ends to easily transition from iron to copper or appliances to system piping. Also available is the new press ball valve with bleeder and reversible handle and large Pro-Pal® Union Ball™ (sizes 1¼” and 1½”) in FIP, sweat, and press. All products feature lead-free dezincification-resistant brass.

Webstone, a brand of NIBCO, announces new press × NPT products including ball valves with reversible handles, elbows, and couplings. Choose between MIP or FIP ends to easily transition from iron to copper or appliances to system piping. Also available is the new press ball valve with bleeder and reversible handle and large Pro-Pal® Union Ball™ (sizes 1¼” and 1½”) in FIP, sweat, and press. All products feature lead-free dezincification-resistant brass.

Learn more at www.webstonevalves.com/press